High precision polishing method and device for arc discharge fiber cross section

An arc discharge, high-precision technology, applied in grinding/polishing equipment, machine tools suitable for grinding workpiece planes, machine tools designed for grinding workpiece rotating surfaces, etc., can solve the problem of large optical signal scattering and absorption loss, device Unfavorable, can not eliminate the micro-crack loss on the surface of the polished optical fiber, to achieve the effect of eliminating roughness and suppressing large loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

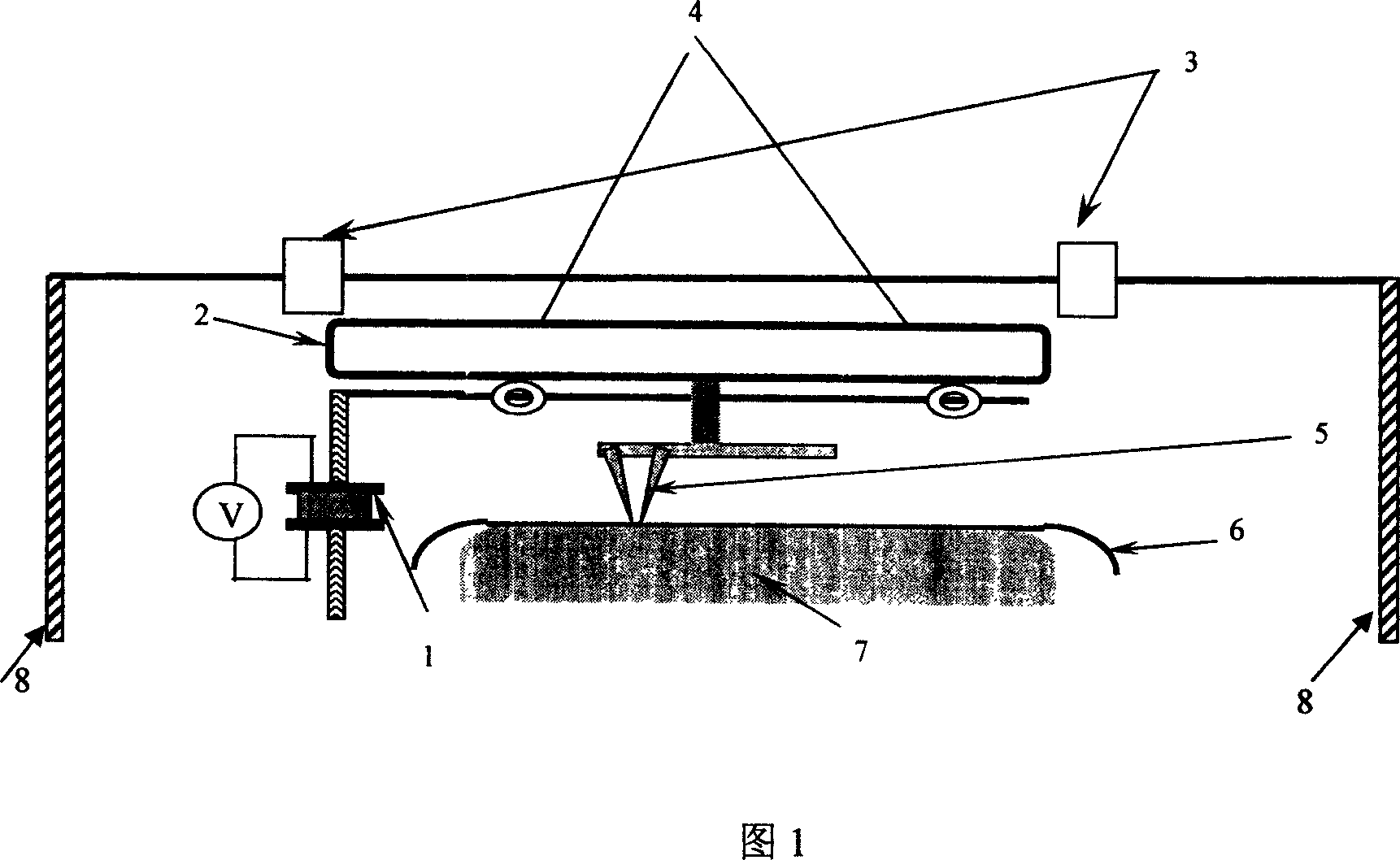

[0019] The present invention designs a high-precision polishing method and device for an arc discharge optical fiber grinding section, and its structure is shown in FIG. 1 .

[0020] In the accompanying drawings, 1 is the PZT height regulator, 2 is the conveyor belt, the transmission speed is controlled by the motor, 3 is the positioning sensor controlled by the relay, 4 is the contact point of the positioning sensor, 5 is the arc discharge electrode, 6 is the optical fiber to be polished after grinding, 7 is glass-ceramic for V-shaped notch optical fiber placement, and 8 is a positioning sensor support frame.

[0021] In order to polish the surface of the polished optical fiber, so as to remove the microcrack damage on the surface of the polished optical fiber and improve the performance of the device, the present invention uses the high temperature effect generated by arc discharge to melt the surface of the polished optical fiber, thereby effectively eliminating microcracks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com