3D printing pen

A 3D printing pen and pen holder technology, applied in the field of 3D printing pens, can solve the problems of 3D printing pen quality and cost impact, and achieve the effect of stable and reliable 3D printing effect, simple structure and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

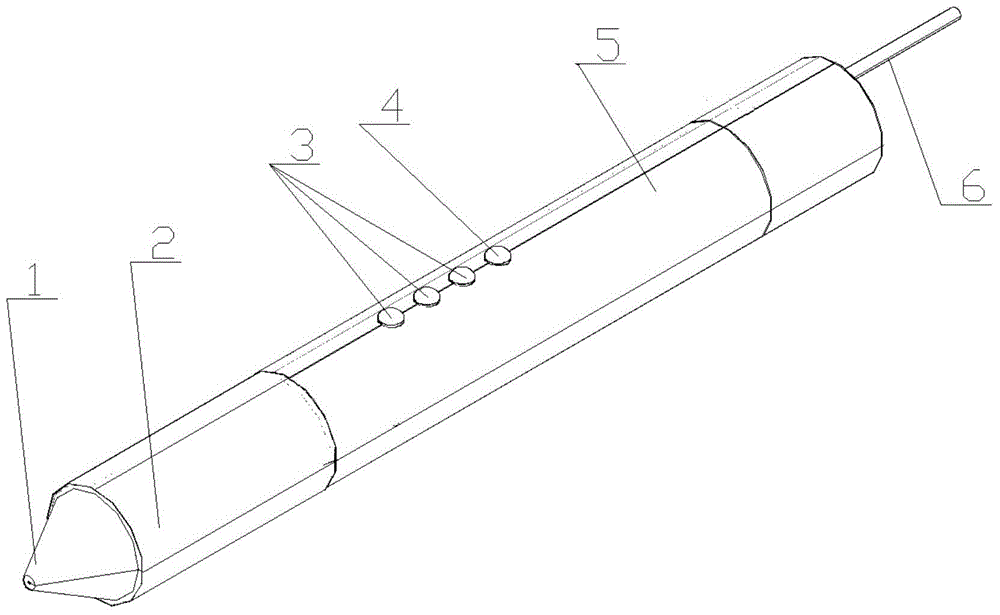

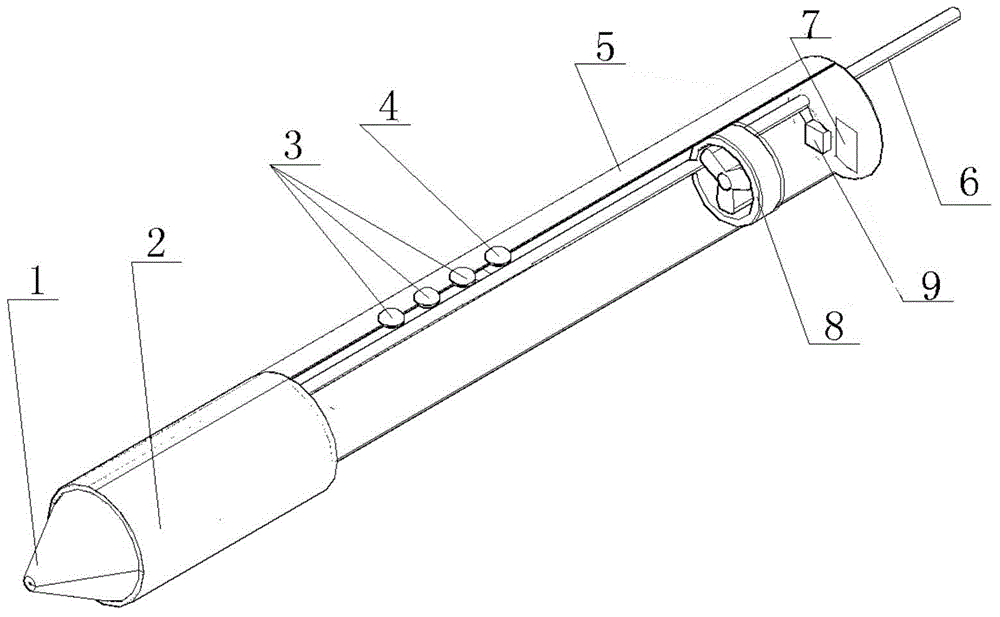

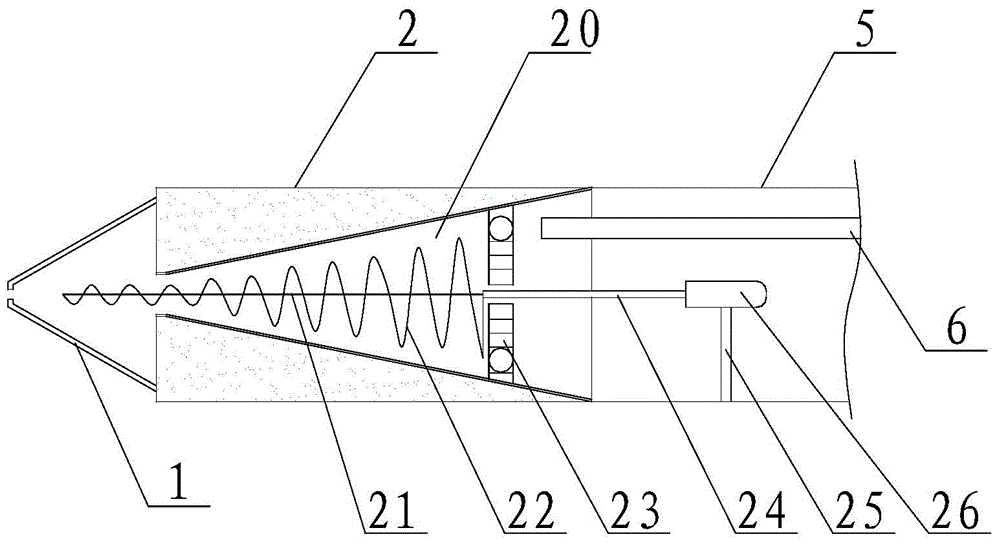

[0020] Such as figure 1 , figure 2 and image 3 As shown, the 3D printing pen of the present invention includes a pen holder 5, a nib 1 and a refill 6, an extrusion cylinder 2 is arranged between the pen holder 5 and the nib 1, and an extrusion cavity 20 is opened in the extrusion cylinder 2 , the extrusion chamber 20 communicates with the nib 1, the extrusion chamber 20 is provided with a heater 23 for melting the refill 5 and a screw conveying assembly for transporting the molten refill 5, the auger conveying assembly It includes a rotating shaft 21 and a helical blade 22 installed on the rotating shaft 21. One end of the rotating shaft 21 extends into the nib 1, and the other end of the rotating shaft 21 is connected to the second drive motor 26 through a connecting rod 24. The second Drive motor 26 is fixedly arranged in pen holder 5 by bracket 25, and described pen holder 5 is provided with speed regulating button 3 and switch button 4, and described pen holder 5 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com