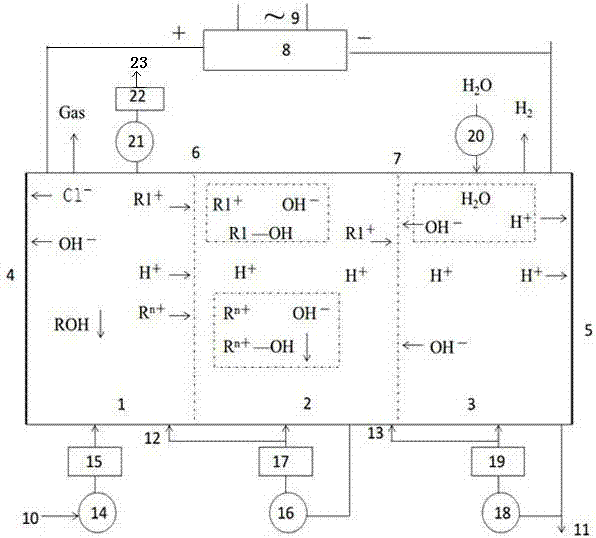

Method for preparing high-purity benzyltrimethylammonium hydroxide by continuous electrolysis with three chambers and two membranes

A technology of benzyltrimethylammonium hydroxide and high-purity benzyltrimethyl, which is applied in the direction of electrolysis process, electrolysis components, electrolysis organic production, etc. It can solve the problems of difficult large-scale safe production, low product purity and large amount of waste water To achieve the effect of improving current efficiency and product conversion rate, reducing energy consumption and saving membrane cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] At a temperature of 25°C, add a 30% benzyltrimethylammonium chloride solution into the anode compartment 1, and the current density is 800A / m 2 , after the electrolysis reaction, the middle chamber 2 and the cathode chamber 3 have a concentration of 25% benzyltrimethylammonium hydroxide. The concentration of each metal ion in the product is less than 20 ppb, and the chloride ion is less than 1ppm (see Table 1); the current efficiency is 61%, and the product conversion rate is 98.2%.

Embodiment 2

[0038] At 25°C, add a 50% benzyltrimethylammonium chloride aqueous solution into the anode chamber 1, and use a current density of 1500A / ㎡. After the electrolysis reaction, the middle chamber 2 and the cathode chamber 3 have a concentration of 25%. Benzyltrimethylammonium Hydroxide. The concentration of each metal ion in the product is less than 20 ppb, and the chloride ion is less than 1ppm (see Table 1); the current efficiency is 63%, and the product conversion rate is 98.3%.

Embodiment 3

[0040] At a temperature of 50°C, add a 50% benzyltrimethylammonium chloride aqueous solution into the anode chamber 1, and the current density is 1500 A / m 2 , after the electrolysis reaction, the middle chamber 2 and the cathode chamber 3 have a concentration of 25% benzyltrimethylammonium hydroxide. The concentration of each metal ion in the product is less than 20 ppb, and the chloride ion is less than 1ppm (see Table 1); the current efficiency is 69%, and the product conversion rate is 98.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com