Preparation method of antistatic acrylic plus material

An antistatic and antistatic finishing agent technology, applied in the treatment of textile materials, continuous treatment of textile materials, treatment of materials with two or more different solvent bases, etc., can solve the problem of polymer polymerization stability, anti-static The problem of high thermal stability of the electrostatic agent is required to achieve the effect of reducing the drape and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

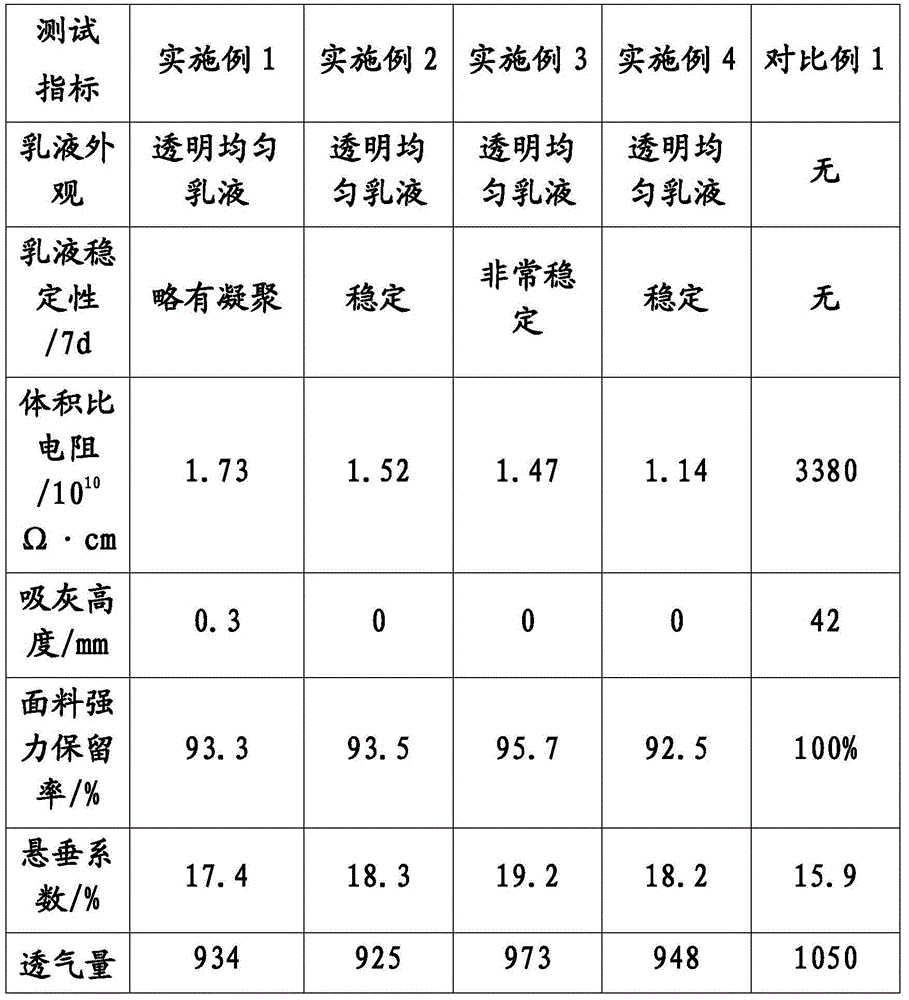

Examples

Embodiment 1

[0025] The preparation steps of antistatic acrylic fiber fabric are as follows:

[0026] (1) Use detergent to clean the acrylic knitted fabric and dry it;

[0027] (2) Dip the above-mentioned acrylic knitted fabric in the antistatic finishing agent, heat to 70°C, and keep warm for 30min;

[0028] (3) Take out the above-mentioned acrylic knitted fabric, and use a padding machine to squeeze liquid, and the excess rolling rate is 100%.

[0029] (4) Drying the acrylic fiber fabric after liquid squeezing, the drying temperature is 100° C., the drying temperature is 120° C., washed with water, and dried.

[0030] Wherein the composition of antistatic agent is as follows:

[0031] Acrylate 1%,

[0032] Sodium Lauryl Sulfate 2%,

[0033] Tin dioxide 1%,

[0034] Titanium Dioxide 1%,

[0035] ethanol 5%,

[0036] 90% water.

[0037] The above antistatic agent is emulsified and dispersed by using a high shear emulsifier to prepare an antistatic finishing agent.

Embodiment 2

[0039] The preparation steps of antistatic acrylic fiber fabric are as follows:

[0040] (1) Use detergent to clean the acrylic knitted fabric and dry it;

[0041] (2) Dip the above-mentioned acrylic knitted fabric in the antistatic finishing agent, heat to 40°C, and keep warm for 20min;

[0042] (3) Take out the above-mentioned acrylic knitted fabric, and use a padding machine to squeeze liquid, and the excess rolling rate is 60%.

[0043] (4) Drying the acrylic fiber fabric after liquid squeezing, the drying temperature is 80° C., the curing temperature is 100° C., washed with water, and dried.

[0044] The composition of antistatic agent is as follows:

[0045] Acrylate 1%,

[0046] Cetyltrimethylammonium Bromide 2%,

[0047] Antimony-doped tin oxide 1%,

[0049] Ethanol 6%,

[0050] Distilled water 89%.

[0051] The above antistatic agent is emulsified and dispersed by using a high shear emulsifier to prepare an antistatic finishing agent. ...

Embodiment 3

[0053] The preparation steps of antistatic acrylic fiber fabric are as follows:

[0054] (1) Use detergent to clean the acrylic knitted fabric and dry it;

[0055] (2) Dip the above-mentioned acrylic knitted fabric in the antistatic finishing agent, heat to 60°C, and keep warm for 30min;

[0056] (3) Take out the above-mentioned acrylic knitted fabric, and use a padding machine to squeeze liquid, and the excess rolling rate is 80%.

[0057] (4) Drying the acrylic fiber fabric after liquid squeezing, the drying temperature is 90° C., the curing temperature is 110° C., washed with water, and dried.

[0058] The composition of antistatic agent is as follows:

[0059] Acrylate 1%,

[0060] Sodium Lauryl Sulfate 2%,

[0061] Indium-doped tin oxide 1%,

[0063] Ethanol 8%,

[0064] Distilled water 87%.

[0065] The above antistatic agent is emulsified and dispersed by using a high shear emulsifier to prepare an antistatic finishing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com