Antistatic acrylic plus material

An antistatic and acrylic technology, applied in fiber types, textiles and papermaking, fiber treatment, etc., can solve the problems affecting the polymerization stability of polymers, high thermal stability requirements of antistatic agents, etc., and achieve drape and air permeability reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

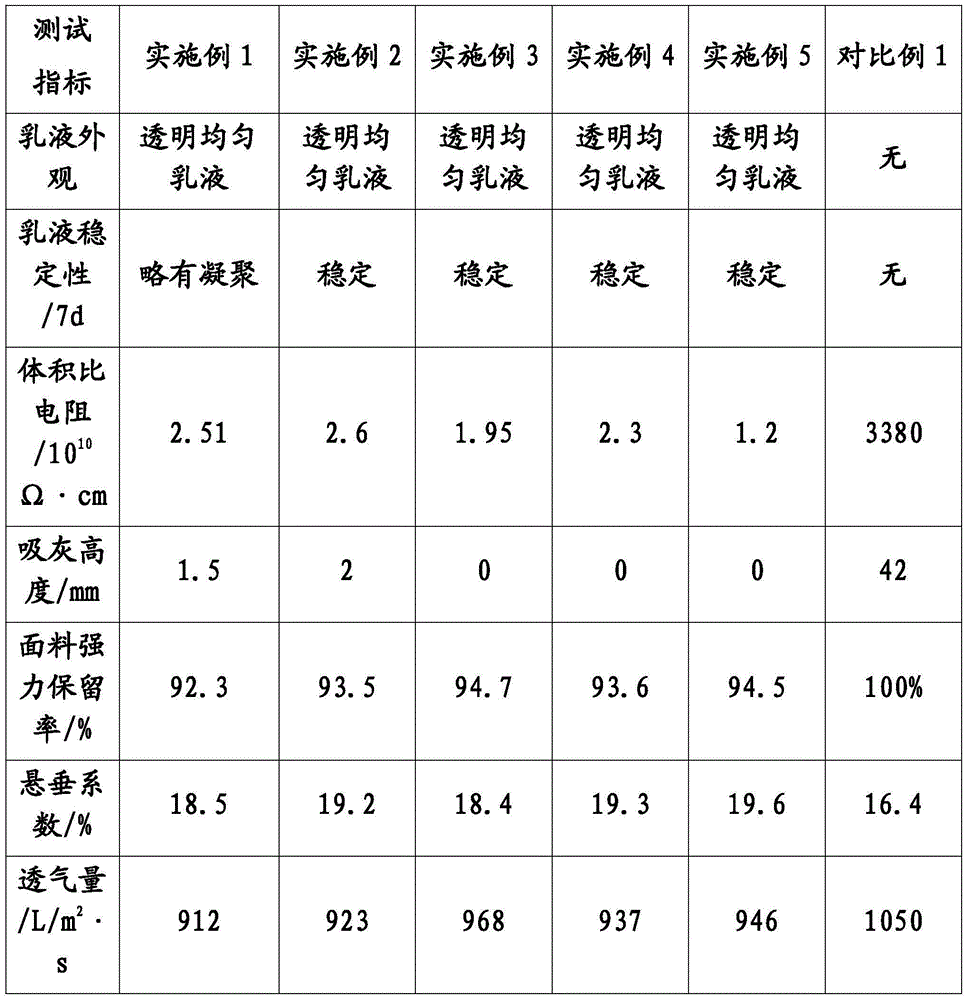

Examples

Embodiment 1

[0020] (1) The base layer of the antistatic acrylic fabric is 21S / 2 acrylic knitted fabric

[0021] (2) Antistatic finishing agent consists of:

[0022] Sodium Lauryl Sulfate 1%,

[0023] Ammonium Citrate 1%,

[0024] Tin dioxide 2%,

[0025] Acrylic resin 2%,

[0026] Ethanol 5%,

[0027] Water 89%.

[0028] A high-speed shearing machine is used to disperse each component to prepare an antistatic finishing solution.

[0029] (3) Preparation process of antistatic acrylic fabric

[0030] Immerse the acrylic knitted fabric in the above finishing solution, take it out after 30 minutes, pad the finishing solution, pre-dry at 80°C, bake at 100°C, wash with water, and dry to obtain an antistatic acrylic fabric.

Embodiment 2

[0032] (1) The base fabric of the antistatic acrylic fabric is 21S / 2 acrylic knitted fabric

[0033] (2) Antistatic finishing agent consists of:

[0034] Cetyltrimethylammonium Bromide 1.5%,

[0035] Sodium hexametaphosphate 1%,

[0037] Acrylic resin 2%,

[0038] Ethanol 6%,

[0039] Water 87.5%.

[0040] A high-speed shearing machine is used to disperse each component to prepare an antistatic finishing solution.

[0041] (3) Preparation process of antistatic acrylic fabric

[0042] Immerse the acrylic knitted fabric in the above finishing solution, take it out after 30 minutes, pad the finishing solution, pre-dry at 80°C, bake at 100°C, wash with water, and dry to obtain an antistatic acrylic fabric.

Embodiment 3

[0044] (1) The base fabric of the antistatic acrylic fabric is 21S / 2 acrylic knitted fabric

[0045] (2) Antistatic finishing agent consists of:

[0046] Cetyltrimethylammonium Bromide 2%,

[0047] Sodium hexametaphosphate 1%,

[0048] Antimony-doped tin oxide 2%,

[0049] epoxy resin 2%,

[0050] Ethanol 4%,

[0051] Water 89%.

[0052] A high-speed shearing machine is used to disperse each component to prepare an antistatic finishing solution.

[0053] (3) Preparation process of antistatic acrylic fabric

[0054] Immerse the acrylic knitted fabric in the above finishing solution, take it out after 30 minutes, pad the finishing solution, pre-dry at 80°C, bake at 100°C, wash with water, and dry to obtain an antistatic acrylic fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com