Floating slab and its floating track bed

A floating track bed and floating slab technology, applied in the field of rail transit, can solve the problems of restricting large-scale popularization and application, weak resistance to bending moment, restricting the speed of construction, etc., achieving reasonable stress, reasonable vibration characteristics, and improved use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

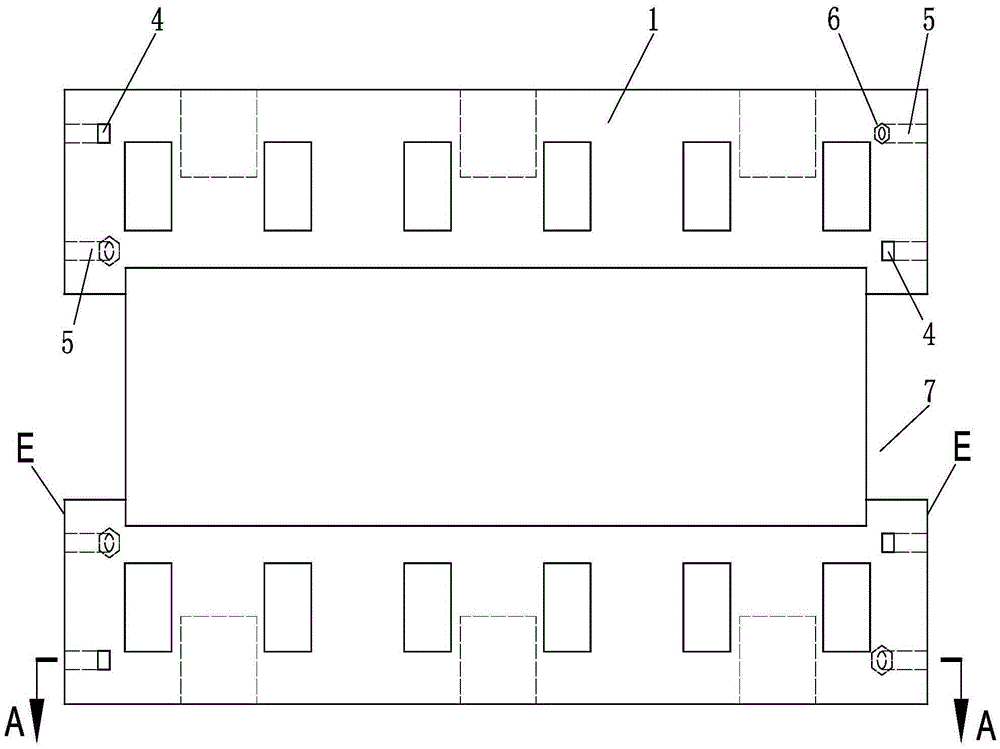

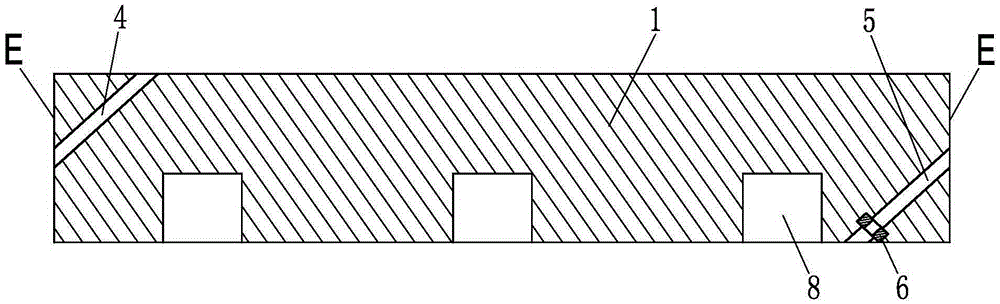

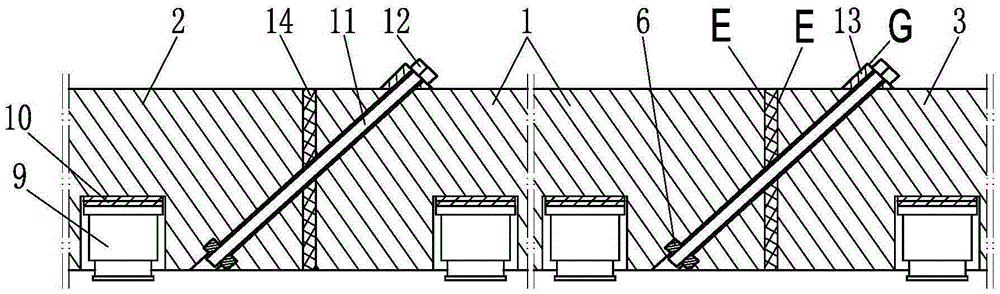

[0047] like figure 1 and figure 2 The floating plate of the present invention as shown includes a floating plate body 1, and observation ports 7 are provided at both ends of the floating plate body 1, and an installation reserved space 8 for matching with an elastic vibration isolation device is provided on the floating plate body 1, The connection ends on both sides of the floating plate body 1 are respectively provided with a first assembly hole 4 and a second assembly hole 5, the transverse vertical end surface at the connection end is the connection mating surface E, the first assembly hole 4 and the second assembly hole The two assembly holes 5 are all arranged in the longitudinal vertical plane of the floating plate body; the first assembly hole 4 runs through the floating plate body 1 obliquely, its upper opening is located on the top surface of the floating plate body 1, and the lower opening is located on the top surface of the floating plate body 1. On the connecti...

Embodiment 2

[0063] like Figure 4 , Figure 5 Shown is the floating plate of the present invention, with figure 1 , figure 2 The difference of the floating plate shown is that the floating plate body 1 is provided with a connecting sleeve 17 that cooperates with the elastic vibration isolation device, and each connection end of the floating plate body 1 is respectively provided with three first assembly holes 4 and three A second assembly hole 5, a groove 15 is arranged on the top surface of the floating plate body 1 corresponding to the upper opening of the first assembly hole 4, and the bottom surface of the groove 15 forms a locking shoulder G, which is perpendicular to the locking shoulder G. The central axis of the first assembly hole 4 is set. In addition, the floating plate body 1 is provided with an observation port 2, of course, the observation port 2 is closed by the end cover during use to prevent foreign objects from falling. In addition, the lower opening of the second a...

Embodiment 3

[0069] like Figure 9 Shown is the floating plate of the present invention, with Figure 4 and Figure 5 The difference of the floating plate shown is that the assembly interface in the floating plate body 1 is the articulated shoulder provided at the lower part of the second assembly hole 5, and the articulated shoulder is integrated and fixed in the concrete structure at the lower part of the second assembly hole. Metal articulated plate 20 is formed, and the middle part of articulated retaining shoulder is provided with installation through hole 21, and the outline shape of installation through hole 21 is rectangle; In addition, the connecting end of floating plate body 1 is respectively provided with adjacent floating plate. The anti-displacement structure of limited fit, the anti-displacement structure includes a convex structure or a groove structure, wherein a convex structure composed of a limit pin shaft 22 is provided on one side of the connection end, and a limit p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com