Rail collection guidance and rail pushing trolley and long steel rail transport train set

A trolley and telescopic boom technology, applied in tracks, laying tracks, moving track parts, etc., can solve problems such as hidden safety hazards and low work efficiency, and achieve the effects of strong reliability, improved safety and efficiency, and strong bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

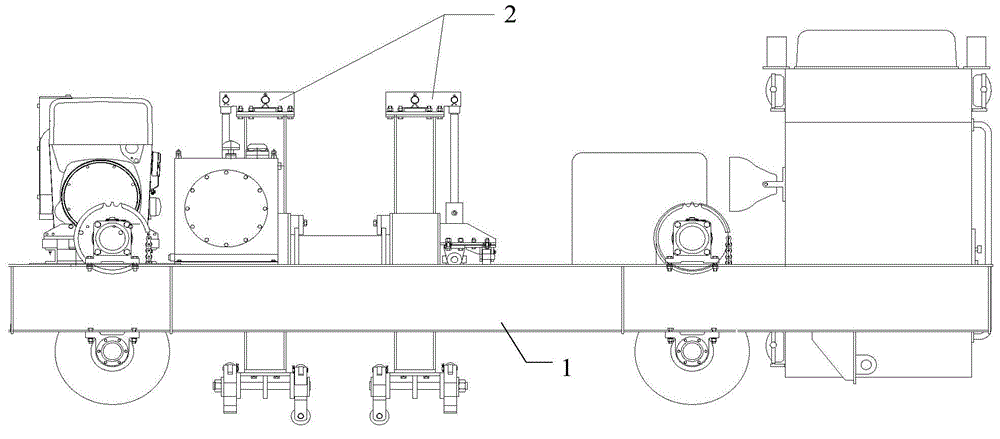

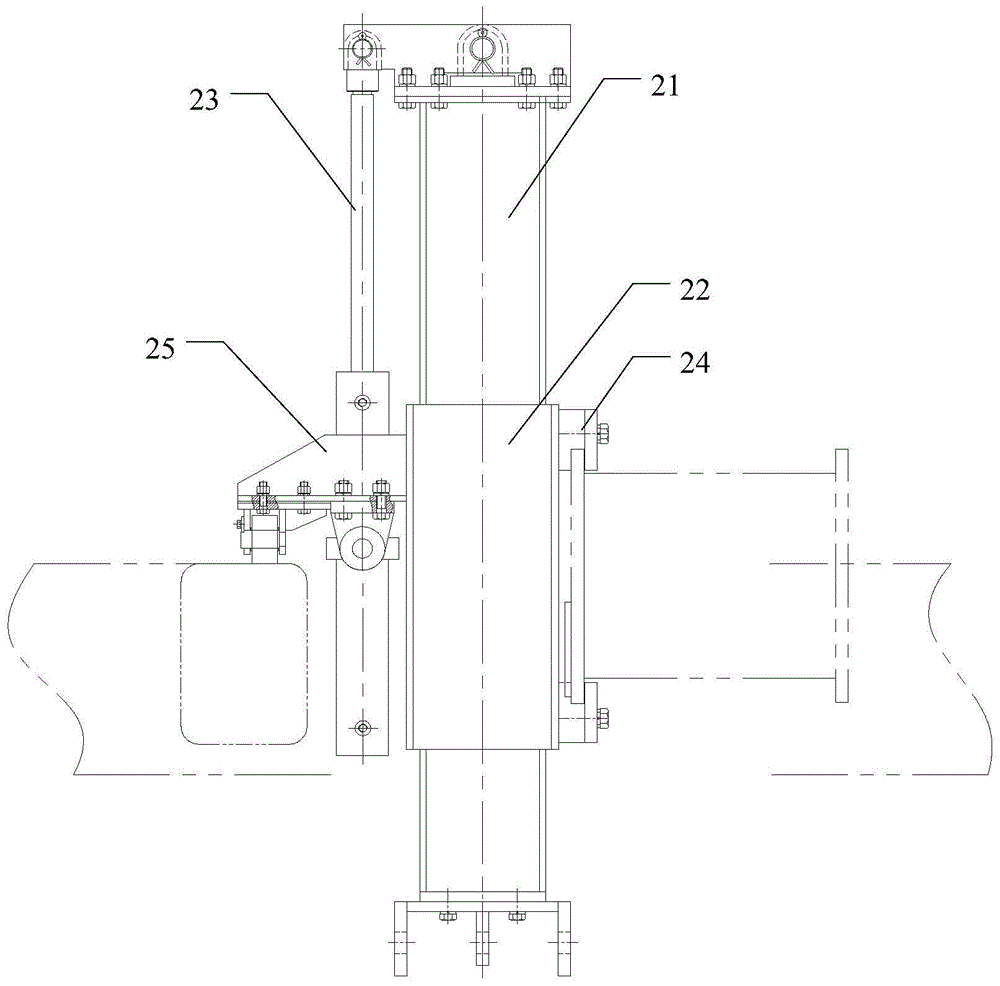

[0060] figure 1 It is a schematic structural diagram of the rail receiving guide and rail shifting trolley provided by Embodiment 1 of the present invention. figure 2 It is a schematic structural diagram of the telescopic arm assembly in the rail receiving guide and rail shifting trolley provided by Embodiment 1 of the present invention. Such as figure 1 and figure 2As shown, the rail receiving guide and rail shifting trolley provided by this embodiment includes: trolley body 1 and telescopic arm assembly 2;

[0061] The telescopic arm assembly 2 includes: a telescopic arm body 21, a sliding arm 22 sleeved outside the telescopic arm body 21, and a first hydraulic cylinder 23 for driving the telescopic arm body 21 to move axially along the sliding arm 22;

[0062] The two sides of the sliding arm 22 are respectively supported on the trolley body 1 by the first support member 24 and the second support member 25;

[0063] The bottom end of the telescopic arm body 21 is fixe...

Embodiment 2

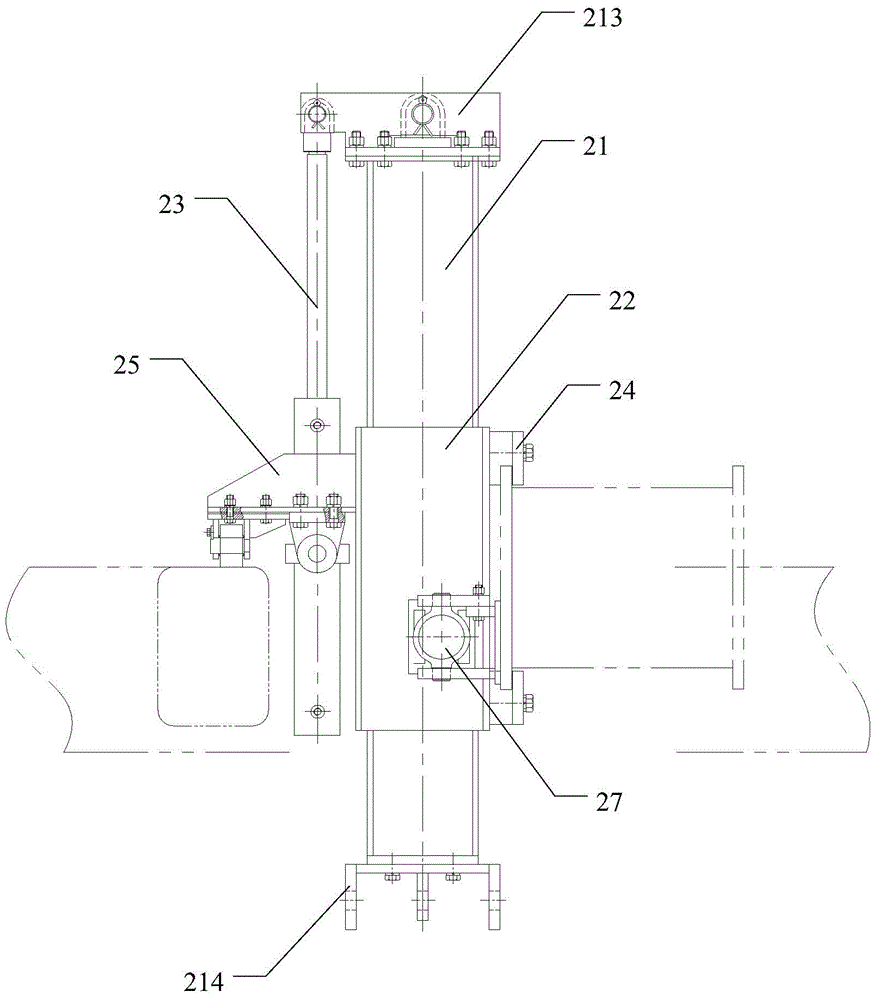

[0068] image 3 Schematic diagram of the structure of the telescopic arm assembly in the rail receiving guide and rail shifting trolley provided by Embodiment 2 of the present invention; Figure 4 for image 3 Side view of telescoping arm assembly shown. In this embodiment, on the basis of the technical solution provided in the first embodiment, a second hydraulic cylinder 26 and a horizontal hydraulic cylinder 27 are added to further drive the telescopic arm body 21 to move. Such as image 3 and Figure 4 As shown, the rail-receiving guide and track-shifting trolley in this embodiment includes: a trolley body 1 and a telescopic arm assembly 2, and the telescopic arm assembly 2 includes: a telescopic arm body 21, a sliding slide set outside the telescopic arm body 21 The arm 22 and the first hydraulic cylinder 23 for driving the telescopic arm body 21 to move axially along the sliding arm 22 .

[0069] Wherein, the telescopic arm body 21 includes: a first telescopic arm 2...

Embodiment 3

[0084] Embodiment 3 of the present invention provides a long rail transport train set, including the rail receiving guide and rail shifting trolley described in any of the above embodiments. The long rail transport train set of this embodiment is used for laying and reclaiming rails, and the structure and function of the rail receiving guide and the rail shifting trolley are similar to those of the foregoing embodiments, and will not be repeated here.

[0085] In the long rail transport car set provided in this embodiment, a sliding arm 22 is supported on the body of the rail receiving guide and the rail shifting trolley, and the sliding arm 22 and the telescopic arm body 21 are connected by the first hydraulic cylinder 23, and the telescopic arm body The bottom end of 21 is fixed with a fixture for clamping the old rail. The extension and shortening of the piston rod of the first hydraulic cylinder 23 can drive the fixture to move up and down. Due to the small volume of the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com