Landfill liquid guide and drainage system

A landfill and liquid technology, applied in waterway systems, sewer pipe systems, layered products, etc., can solve problems such as leachate or groundwater cannot be discharged smoothly, drainage systems are easily blocked, and environmental damage is achieved, so as to improve liquid Efficiency of drainage, reduction of liquid residence time, and effect of increasing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

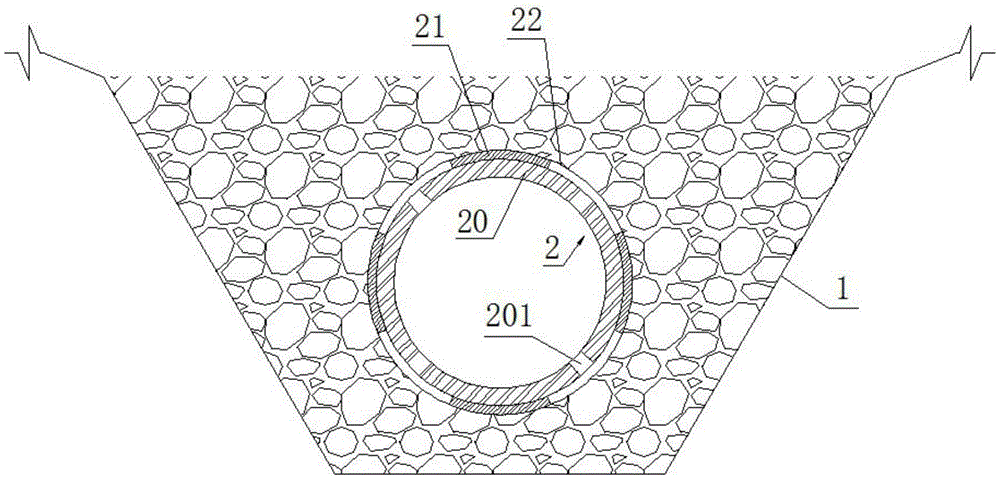

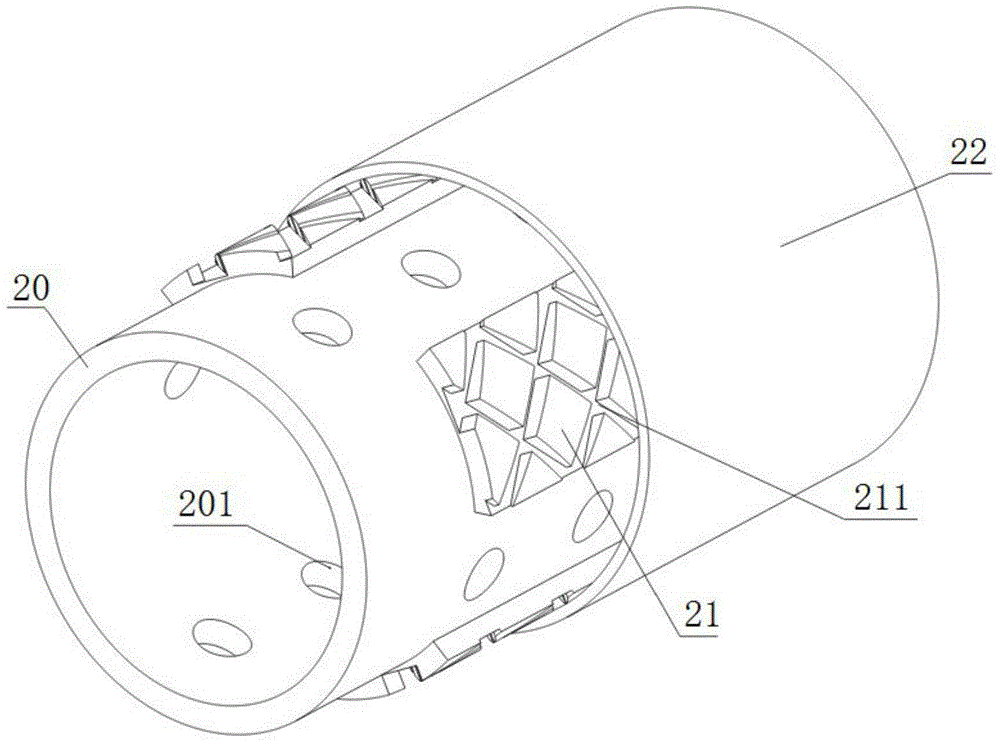

[0021] Such as figure 1 , figure 2 As shown, a landfill liquid drainage system according to the present invention includes a diversion blind ditch 1 and a drainage guide device 2 installed in the diversion blind ditch 1, and the drainage guide device 2 consists of flower tubes 20 and The outer wrapping layer 22 is composed of a plurality of filter holes 201 arranged on the flower tube 20 , and a cushion layer 21 is arranged on the outer surface of the flower tube 20 , and the cushion layer 21 is arranged along the axial direction of the flower tube 20 . By adopting this technical solution, the cushion layer 21 is arranged between the floral tube 20 and the outer wrapping layer 22, thereby increasing the space between the floral tube 20 and the outer wrapping layer 22, thereby improvin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com