Water-cooling and air-cooing interactive type heat dissipation device for diesel engine

A technology for heat dissipation device and diesel engine, which is applied to measurement devices, engine cooling, mechanical equipment, etc., can solve problems such as uneven temperature distribution, and achieve the effects of simple structure, improved heat dissipation capacity, and reduced risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

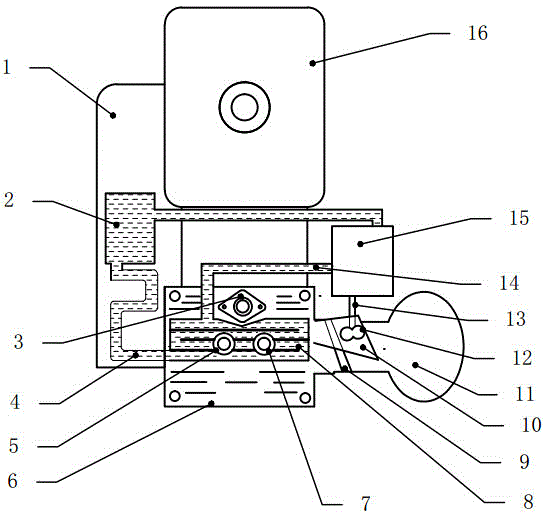

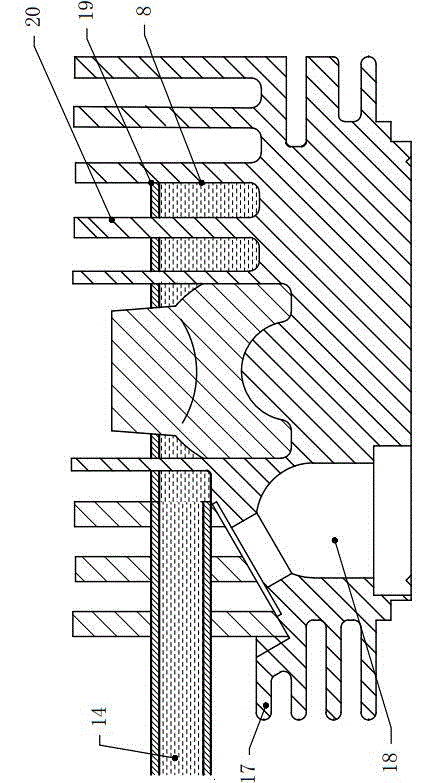

[0020] According to attached Figure 1-4 It can be seen that the present invention specifically relates to a diesel engine water-cooled and air-cooled interactive cooling device, which is a modification of the diesel engine cooling device, so that the diesel engine cylinder has a higher cooling capacity and reduces the risks caused by temperature rise and temperature difference.

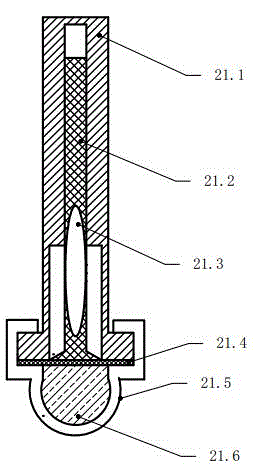

[0021] This cooling device specifically includes an air cooling system, the air cooling system includes a fan, a shroud 1 and a cooling fin 17 positioned on the cylinder liner and the cylinder head 6, the present invention adds a water cooling system on the basis of the original air cooling system of the diesel engine , wherein the water-cooling system includes a micro gear pump 15 and a closed-circuit pipeline connected with the micro gear pump 15, the closed-circuit pipeline is attached to the cylinder head 6, the power input shaft of the micro gear pump 15 is connected with an impeller 12, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com