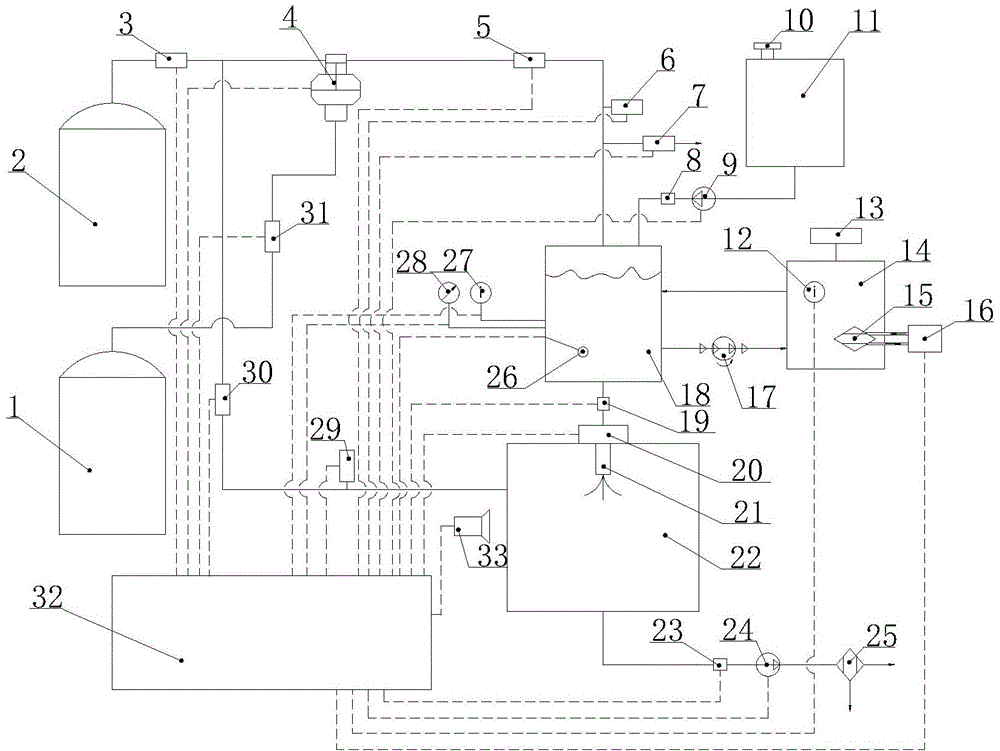

Gasoline engine direct injection type fuel injector performance detecting system

A detection system and fuel injector technology, which is applied in the testing of machine/structural components, charging system, engine testing, etc., can solve the problem of immature detection and research of direct injection fuel injectors, which cannot satisfy the performance of fuel injectors Accurate detection, performance differences of direct injection injectors and other issues, to achieve the effect of solving high-voltage drive and stability problems, improving safety, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0029]A gasoline engine direct-injection fuel injector performance detection system, including a test fluid pressure stabilization and maintenance device, a test fluid pressure adjustment and driving device, a test fluid temperature adjustment device, a test fluid replenishment device, a fuel injector installation device, and a test constant volume Device and control system 32, wherein the test fluid pressure stabilization and maintenance device is a constant temperature and constant pressure tank 18, which is provided with five nitrogen pressure input ports, test liquid replenishment ports, test liquid output ports, and temperature control input and output ports. Interface, pressure sensor 28, temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com