Electric arc heating device capable of generating ultra-high-speed airflow

An arc heating and ultra-high-speed technology, which is applied in the direction of electric heating devices, heating by discharge, and thrust reverse devices, can solve problems such as large gradients, restrictions on the application of arc heating thrusters, and uneven flow fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

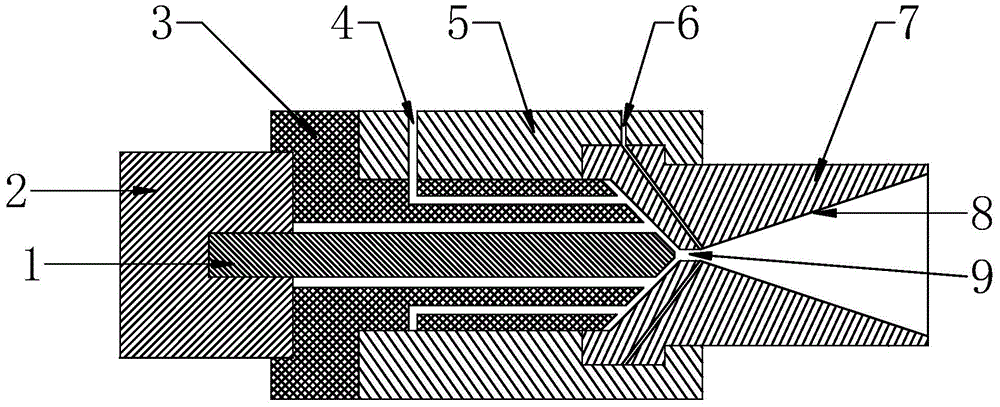

[0016] Such as figure 1 , 2 As shown, the present invention comprises: cathode 1, anode 7 double as nozzle, insulator 3 and metal sheath 5, cathode 1 is fixed on insulator 3 by cathode clip 2, and one end of metal sheath 5 links to each other with insulator 3, The other end is clamped with the anode nozzle 7, and the metal sleeve 5 is provided with an air inlet 4 and an air outlet 6.

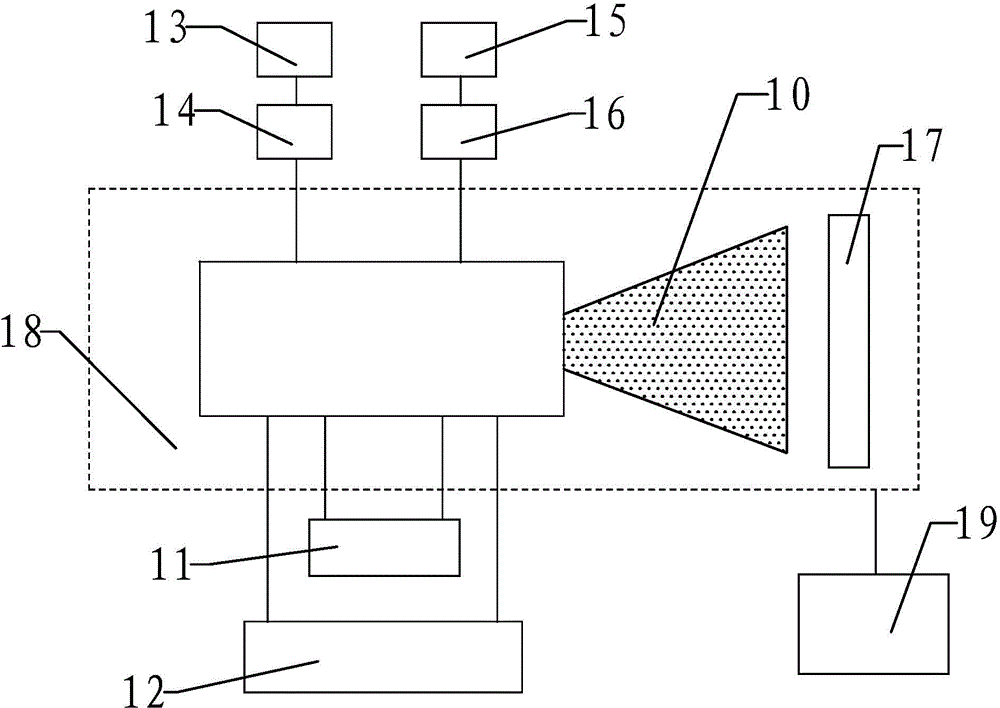

[0017] Mass flow meters 14 and 16 are arranged outside the air inlet 4 and the exhaust port 6. The mass flow meters 14 and 16 are mass flow meters with an accuracy of 3% of the full scale. The mass flow meters 16 connected to the exhaust port 6 An exhaust vacuum pump 15 is also connected. During the operation of the engine, the mass flow meter 16 at the end of the exhaust port 6 and the exhaust vacuum pump 15 also operate, and the mass flow meter 16 is adjusted so that the propellant drawn from the exhaust port is cold and low-speed propellant, and the propellant injected from the engine nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com