Abnormity detection method for natural gas purification process based on analysis of independent component of dynamic kernel

An independent component analysis and process abnormality technology, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc., can solve problems such as failure to detect failures in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

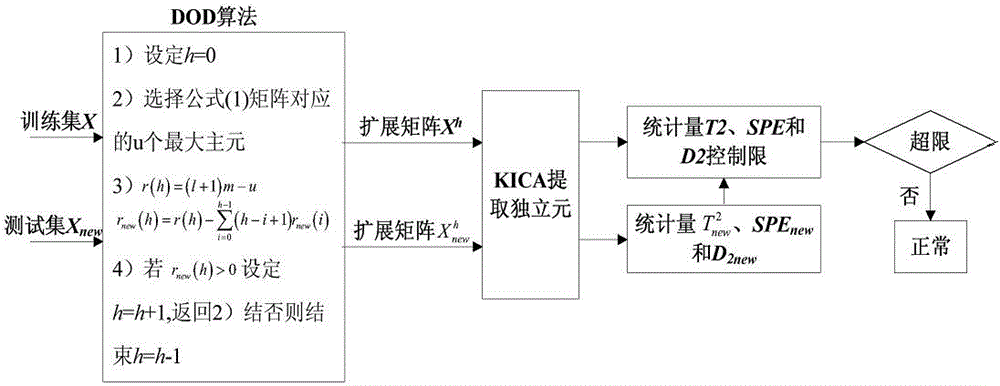

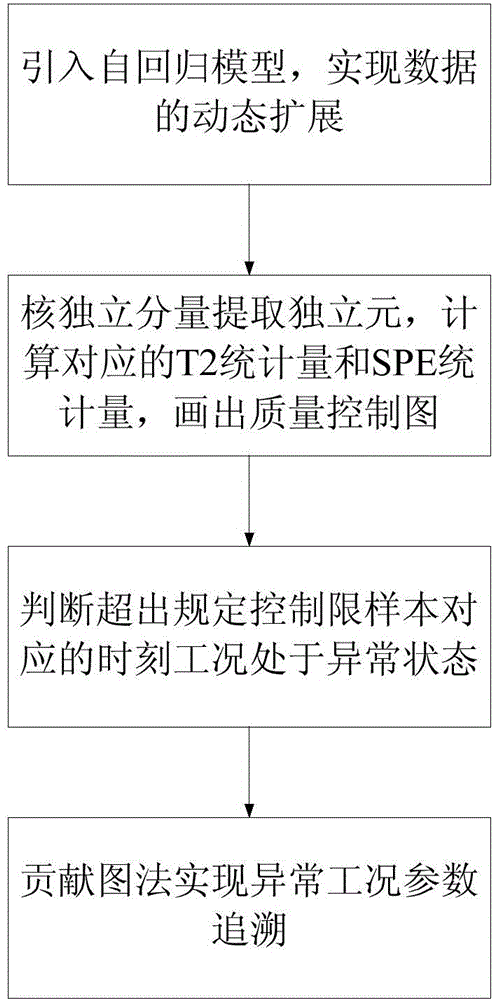

[0041] see image 3 , a method for abnormal detection of natural gas purification process based on dynamic kernel independent component analysis, the diagnosis method is carried out as follows:

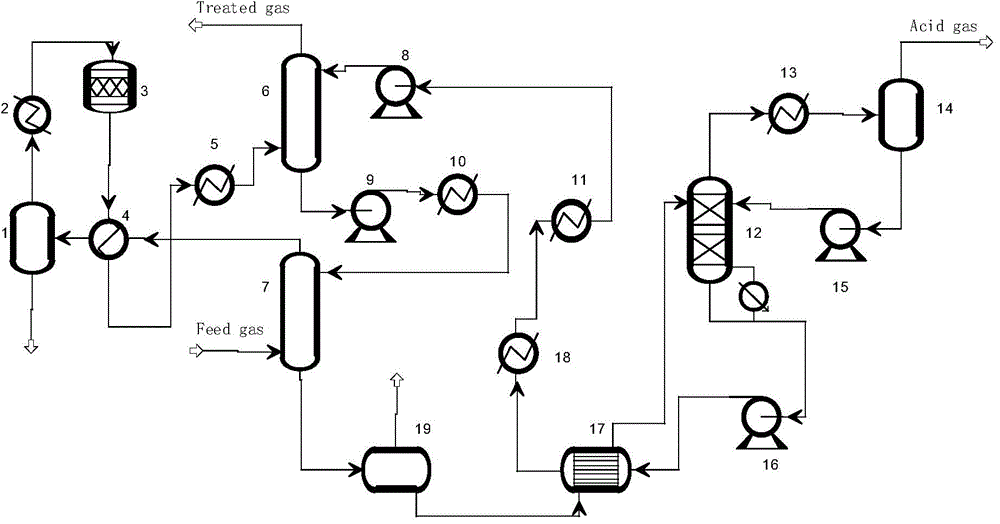

[0042] Step 1: Determine m process parameters in the monitored high-sulfur natural gas purification and desulfurization production process, wherein, m=10, each process parameter is: x 1 Indicates the inlet flow rate of the desulfurization absorption tower amine liquid, x 2 Indicates the inlet flow rate of tail gas absorption tower amine liquid, x 3 Indicates the raw material gas processing capacity, x 4 Indicates the circulating volume of semi-rich amine solution, x 5 Indicates the inlet temperature of the primary absorption tower amine liquid, x 6 Indicates the inlet temperature of the secondary absorption tower amine liquid, x 7 Indicates the flash tank pressure, x 8 Indicates the steam consumption at port A of the reboiler, x 9 Indicates the steam consumption at port B of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com