Grain storage automatic distribution method and device based on reciprocating machine

An automatic shunting and reciprocating machine technology, applied in the field of electronic information, can solve the problems of low degree of automation, inability to meet the needs of large-scale operations, and low operating efficiency, so as to achieve the effect of safe storage and avoiding mildew of grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In large-scale grain reserve depots, the purchased rice will become mildewed due to excessive moisture content. At present, before the rice enters the warehouse, it is mainly manually drawn out for inspection, and it is difficult to control the moisture content. It can only be detected when the water content of the extracted package is too large, which affects the appearance and smell of the grain. Modern grain logistics has changed from packaged grain to bulk grain transportation. Testing instruments are used to detect the moisture content of the online transported grain before the grain enters the warehouse, and the grain with excessive moisture content is kept out of the warehouse door in order to improve the quality of grain storage. This is an important subject that has received much attention in grain reserves.

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in furthe...

Embodiment 2

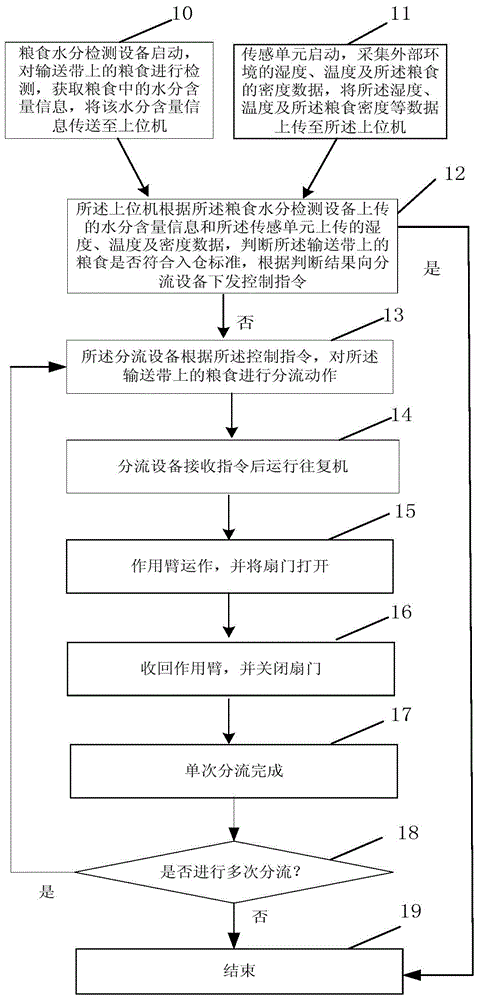

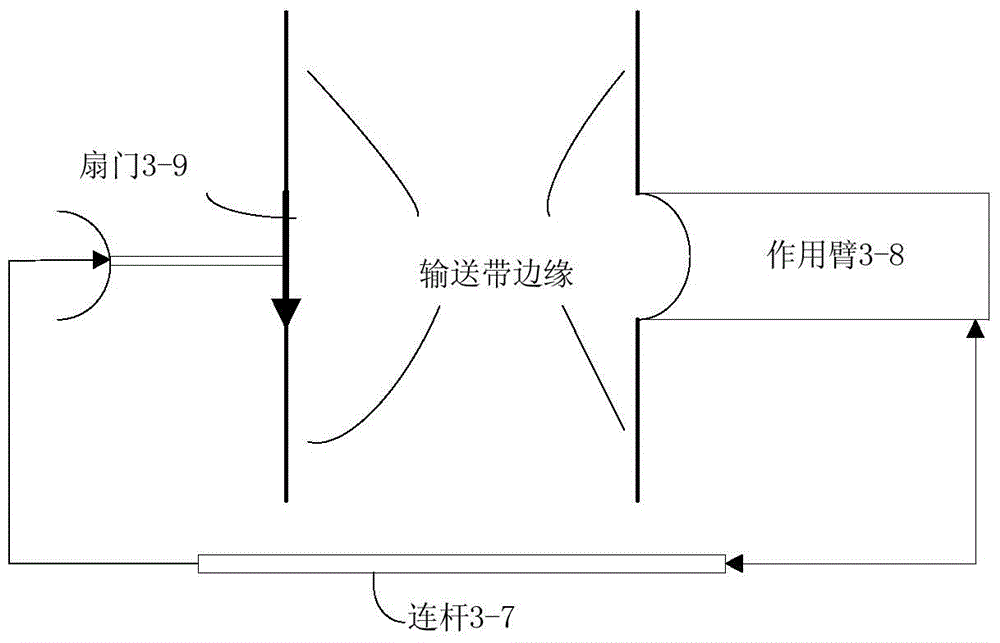

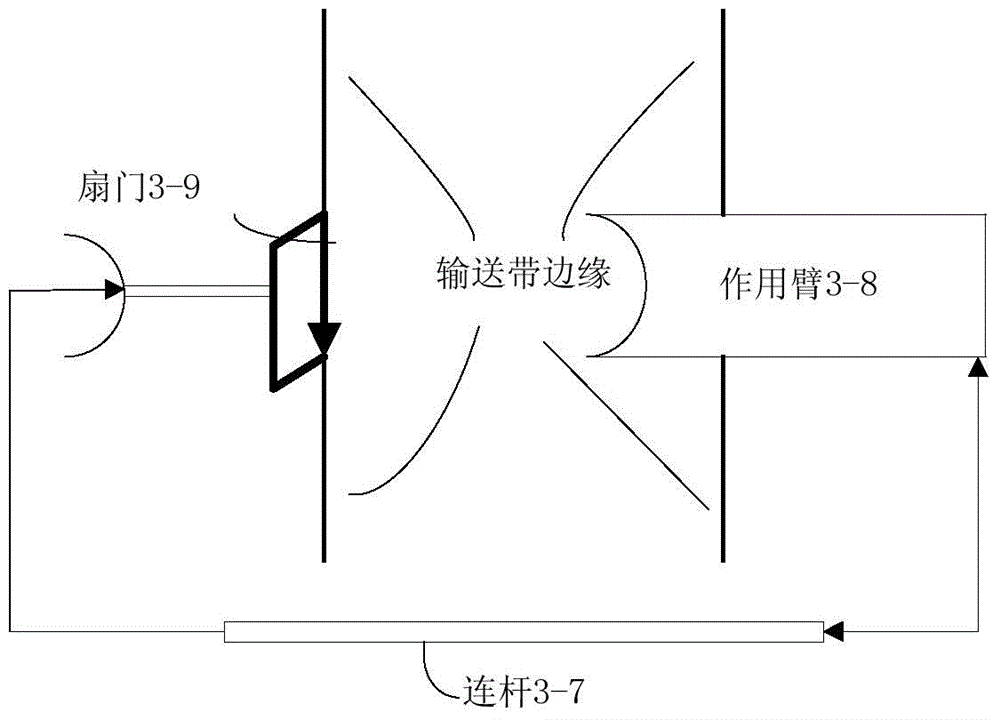

[0063] image 3 It is a structural diagram of a reciprocating machine-based automatic distribution device for grain storage according to an embodiment of the present invention. Such as image 3 As shown, the device includes, including: grain moisture detection equipment, sensing unit, diversion equipment and host computer, the grain moisture detection equipment starts, detects the grain on the conveyor belt, and obtains the moisture content in the grain Information, transmit the moisture content information to the host computer; start the sensing unit, collect the humidity, temperature and grain density data of the external environment, and upload the humidity, temperature and grain density data to the Host computer; the host computer judges whether the grain on the conveyor belt meets the warehousing standard according to the moisture content information uploaded by the grain moisture detection equipment and the humidity and temperature data uploaded by the sensing unit, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com