Post insulator for 1500V rigid overhead contact line

A catenary and insulator technology, applied in the direction of suspension/strain insulators, etc., can solve problems such as not being able to meet creepage distance, withstand strength lightning full-wave impulse withstand voltage, affecting insulator installation and long-term use, and unreasonable insulator size design, etc. , to achieve the effect of facilitating construction and installation, improving connection reliability, and high bearing capacity suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

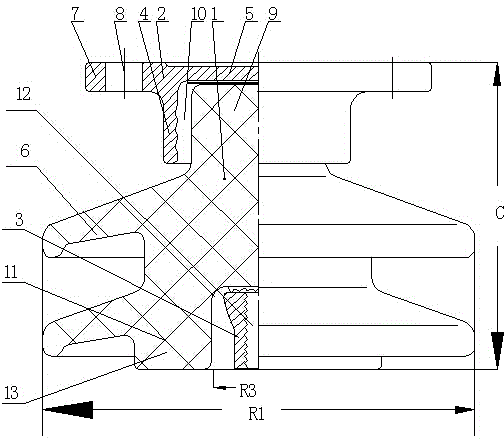

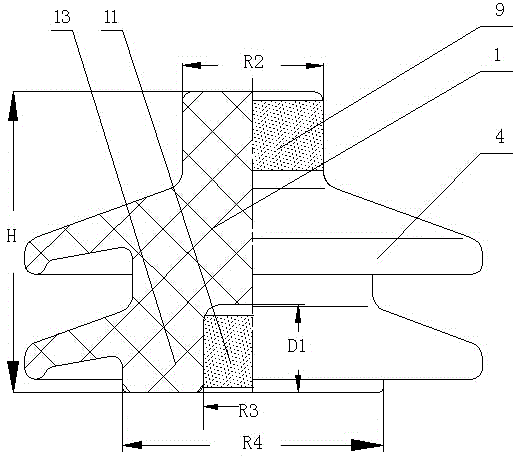

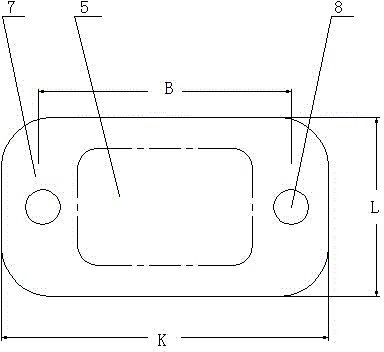

[0033] like figure 1 , 2 As shown in , 3, the post insulator for 1500V rigid overhead catenary includes a porcelain body 1 and a metal attachment, the metal attachment and the porcelain body are glued together, and the metal attachment includes an upper metal attachment 2 and a lower metal attachment 3, and an upper metal attachment The accessory has a lower glued part 4 and an upper top surface 5 above, and an umbrella skirt 6 is arranged in the middle of the porcelain body, and the feature is that both sides of the upper top surface 5 have extensions 7 beyond the glued parts, The extension part and the upper top surface form a rectangular integral structure, such as image 3 As shown, there is a mounting hole 8 on the extensions on both sides, and the diameter of the mounting hole is 18 mm. Described rectangular structure is the shape viewed against the top surface, su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com