Method for the functional control of a sensor for detecting particles and sensor for detecting particles

A functional inspection and sensor technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., to achieve the effects of improving life, reducing evaluation thresholds, and reducing evaluation limits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

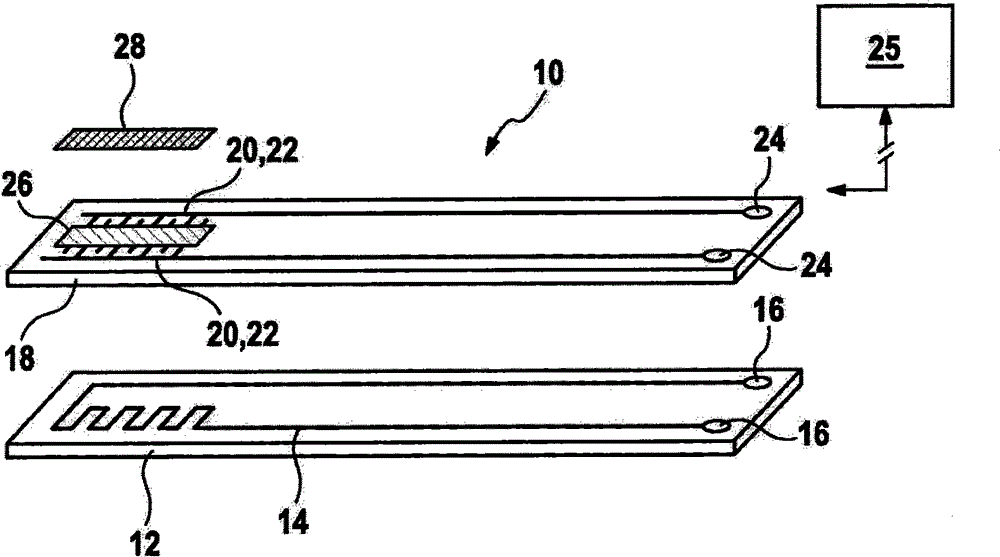

[0032] figure 1 Shown is a sensor 10 for detecting particles, in particular soot, in a gas flow, for example an exhaust gas flow of an internal combustion engine, for installation in the exhaust gas line of a motor vehicle. Sensor 10 is designed, for example, as a soot sensor and is preferably arranged downstream of a soot filter in a motor vehicle with a diesel internal combustion engine.

[0033]The sensor 10 comprises a plate-shaped carrier layer 12 which is at least partially produced from an electrically insulating material, for example from a ceramic such as aluminum oxide. A heating element 14 is integrated in carrier layer 12 , which can be connected to a suitable voltage source via contacts 16 and serves to burn off sensor 10 of possibly deposited particles, such as soot particles.

[0034] Arranged on the carrier layer 12 is a plate-shaped substrate 18 which is at least partially produced from an electrically insulating material, for example from a ceramic such as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com