Double-drive toggle rod mechanism for servo mechanical press and control method thereof

A technology for servo machinery and presses, which is applied in the field of drive toggle mechanism for mechanical presses, can solve problems such as functional limitations of presses with diverse movement modes, and achieve improved performance and applicability, rich functions, and simple and convenient control methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

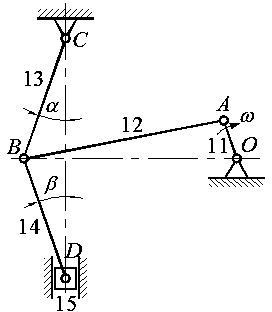

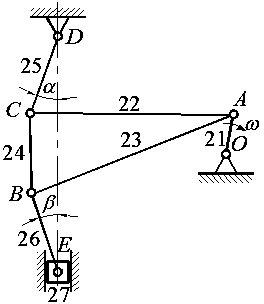

Image

Examples

Embodiment 1

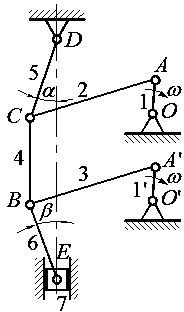

[0029] The schematic diagram of working mechanism of the present invention is as image 3 As shown, the dual-drive toggle mechanism for the servo mechanical press of the present invention includes a first crank 1, a second crank 1′, a first connecting rod 2, a second connecting rod 3, a first toggle 4, a second Toggle 5 and third toggle 6, wherein one end of the first crank 1 is connected with the fuselage to form a revolving pair O, and the other end of the first crank 1 is connected to one end of the first connecting rod 2 to form a revolving pair A. The other end of the rod 2 is respectively connected with one end of the first toggle 4 and one end of the second toggle 5 to form a rotary joint C, and the other end of the second toggle 5 is connected with the fuselage to form a rotary joint D. The second crank 1′ One end of the second crank 1' is connected to the fuselage to form a revolving pair O', the other end of the second crank 1' is connected to one end of the second c...

Embodiment 2

[0034] The schematic diagram of working mechanism of the present invention is as Figure 4 As shown, the difference between the dual-drive toggle mechanism for servo mechanical presses of the present invention and Embodiment 1 is that the other end of the second connecting rod 3 is connected to the other end of the first toggle 4 and the third toggle 6 respectively. One end of the swivel pair B and the other end of the first connecting rod 2 are respectively connected with one end of the first toggle 4 and one end of the second toggle 5 to form a swivel pair C, respectively located on both sides of the axis DE of the fuselage guide rail.

[0035] The working principle of the present invention is: the rotary pair B and the rotary pair C in the toggle mechanism of the present invention are located on both sides of the axis DE, when the slider 7 is at the top dead center, the rotary pair B and the rotary pair C are at a distance from the axis DE furthest position. When working, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com