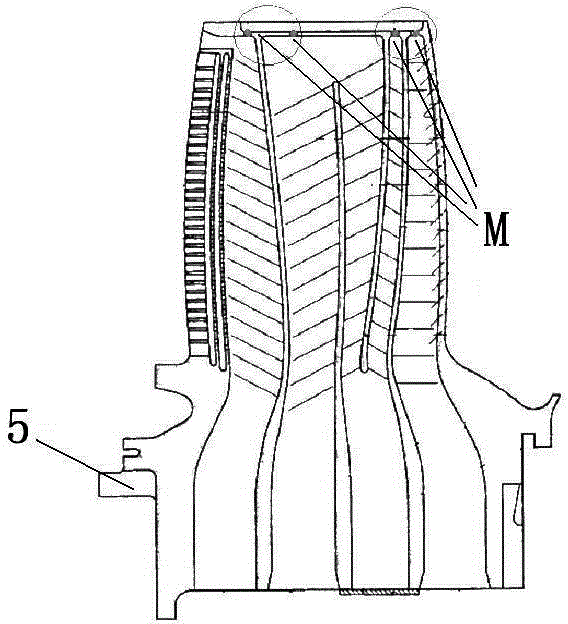

Locally-free-telescopic single crystal blade-used complex-structured ceramic core preparation technology

A technology for ceramic cores and single crystal blades, which is applied in the field of superalloys to achieve the effects of reducing production costs, good economic benefits and engineering application prospects, and ensuring overall integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

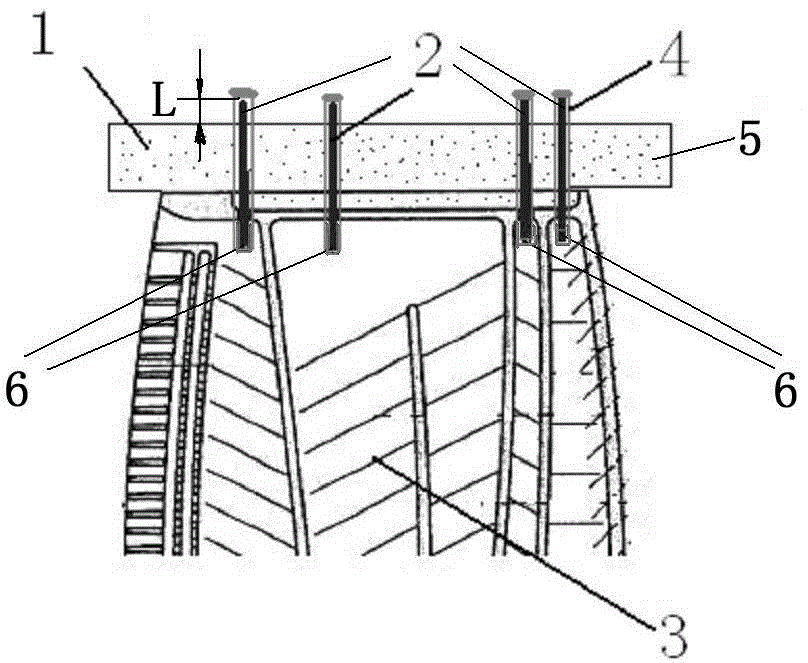

[0039] At first select quartz glass tube as 2# ceramic core, its diameter is 1 millimeter, 2 # ceramic core 2 sides are coated with wax film thickness to be 10 microns, and core end face is coated with wax mold thickness and is 0.5 millimeter;

[0040] 1# and 3# ceramic cores are made of silica material. 1# ceramic core 1 and 3# ceramic core 3 need to reserve a seat hole 6 of the same size as ceramic core 2, the diameter of the seat hole is 10 microns larger than the diameter of 2# ceramic core 2, and the length of the seat hole is 1 mm; 1# ceramic core 1 and 3# ceramic core 3 have independent positioning core head 5, 2# ceramic core 2 is combined with 1# ceramic core 1 and 3# ceramic core 3 on 1# core The length of the outcrop L is 1 mm; the 2# ceramic core 2 is dip-coated with a thin layer of wax film as a whole, and then the 2# ceramic core 2 and the 1# ceramic core 1 and 3# after the dip-coated wax film are treated The ceramic core 3 is combined and put into the wax mold ...

Embodiment 2

[0043] First select the quartz glass tube as the 2# ceramic core, its diameter is 0.6 mm, the thickness of the wax film on the side of the ceramic core 2 is 5 microns, and the thickness of the wax mold on the end face of the core is 0.5 mm;

[0044] 1# and 3# ceramic cores are made of silica material. 1# ceramic core 1 and 3# ceramic core 3 need to reserve a seat hole of the same size as ceramic core 2, the diameter of the seat hole is 10 microns larger than the diameter of core 2, and the length of the seat hole is 1 mm; 1# Ceramic core 1 and 3# ceramic core 3 have independent positioning core heads, and the outcrop size on 1# core after 2# ceramic core 2 is combined with 1# ceramic core 1 and 3# ceramic core 3 is 1 mm; then put the processed 2# ceramic core 2 and 1# ceramic core 1 and 3# ceramic core 3 into the wax mold to press the blade wax mold.

[0045]The injection temperature of the blade wax mold is 65°C, the pressure is 0.3MPa, the injection time is 20 seconds, and ...

Embodiment 3

[0047] First select the quartz glass tube as the 2# ceramic core, its diameter is 2 millimeters, 2 # ceramic core 2 sides are coated with wax film thickness is 30 microns, and core end face is coated with wax mold thickness and is 1.5 millimeters;

[0048] 1# and 3# ceramic cores are made of alumina material. 1# ceramic core 1 and 3# ceramic core 3 need to reserve a seat hole of the same size as ceramic core 2, the diameter of the seat hole is 10 microns larger than the diameter of 2# ceramic core 2, and the length of the seat hole is 3 mm ; 1# ceramic core 1 and 3# ceramic core 3 have independent positioning core heads, 2# ceramic core 2 is combined with 1# ceramic core 1 and 3# ceramic core 3 on the 1# ceramic core The outcrop size is 1 mm; then put the processed 2# ceramic core 2 and 1# ceramic core 1 and 3# ceramic core 3 into the wax mold to press the blade wax mold.

[0049] The injection temperature of the blade wax mold is 55°C, the pressure is 0.3MPa, the injection t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com