Clamping device for cylindrical work-piece line cutting machining

A clamping device and wire cutting technology, applied in the field of mechanical processing, can solve the problems of accuracy requirements affecting dimensional accuracy and shape tolerance, easy deformation, poor rigidity, etc., and achieve low processing accuracy requirements, low production costs, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

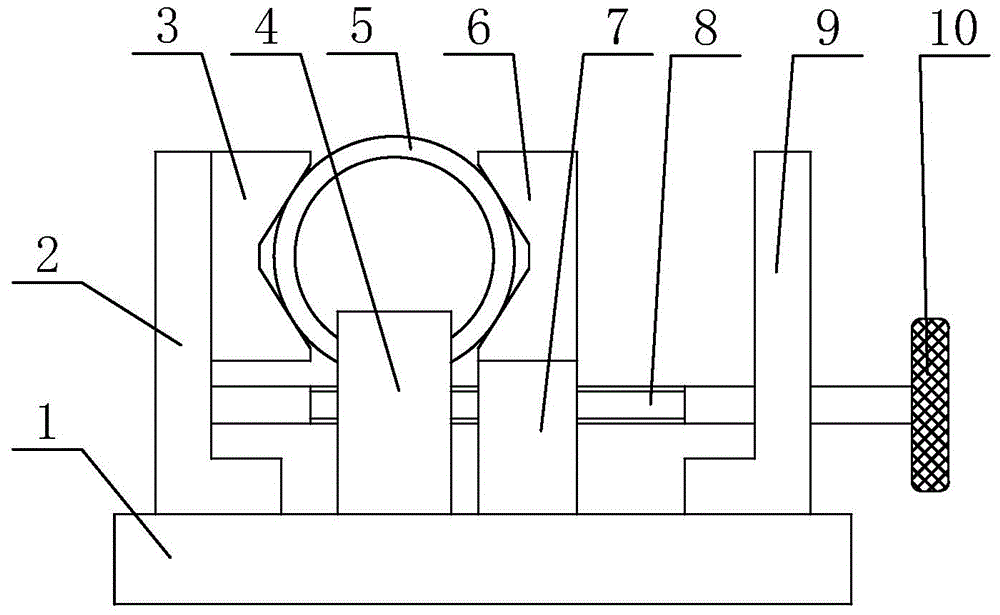

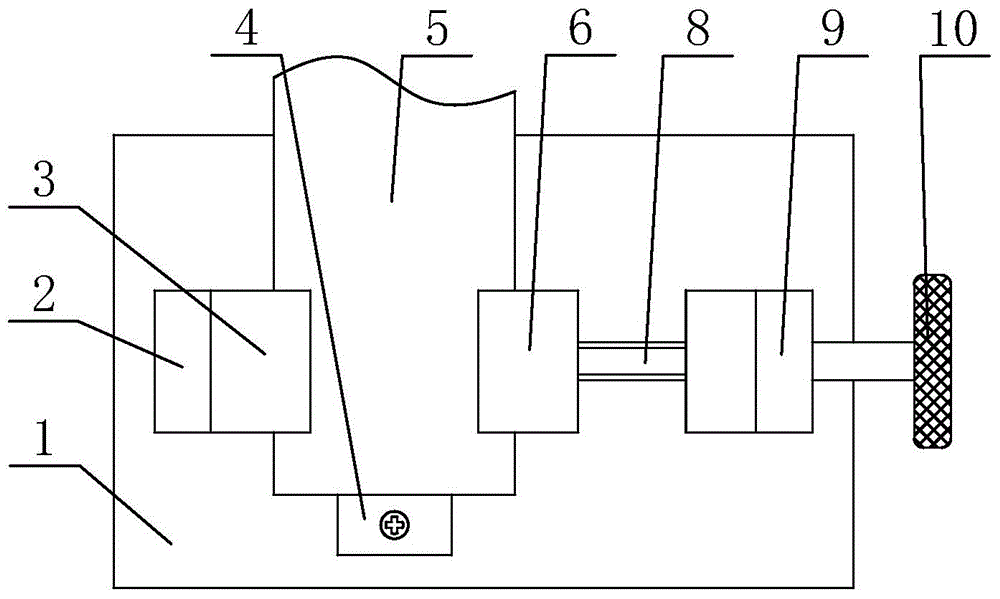

[0019] like figure 1 and figure 2 The shown clamping device for wire cutting processing of a cylindrical workpiece includes a rectangular base 1, a symmetrically arranged L-shaped bracket 1 2 and an L-shaped bracket 2 9, and also includes a positioning device for positioning the end of the workpiece 5 to be processed. Plate 4, the V-shaped cushion block 3 and the V-shaped pressing head 6 for clamping the workpiece 5, the sliding support 7 for supporting the V-shaped pressing head 6 and the sliding support 7 for driving the The upper side of the rectangular base 1 is a screw 8 that moves back and forth; one end of the upper side of the rectangular base 1 is fixedly provided with the L-shaped support 2, and the other end of the upper side of the rectangular base 1 is fixedly provided with the L-shaped support 2 9. A V-shaped spacer 3 is fixedly installed on the L-shaped support 2, and the upper side of the rectangular base 1 is located between the L-shaped support 2 and the L-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com