Three-dimensional moving mechanism for 3D argil printing

A technology of motion mechanism and three-dimensional motion, applied in the field of 3D printing, can solve problems such as complex process and low efficiency, and achieve the effect of broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

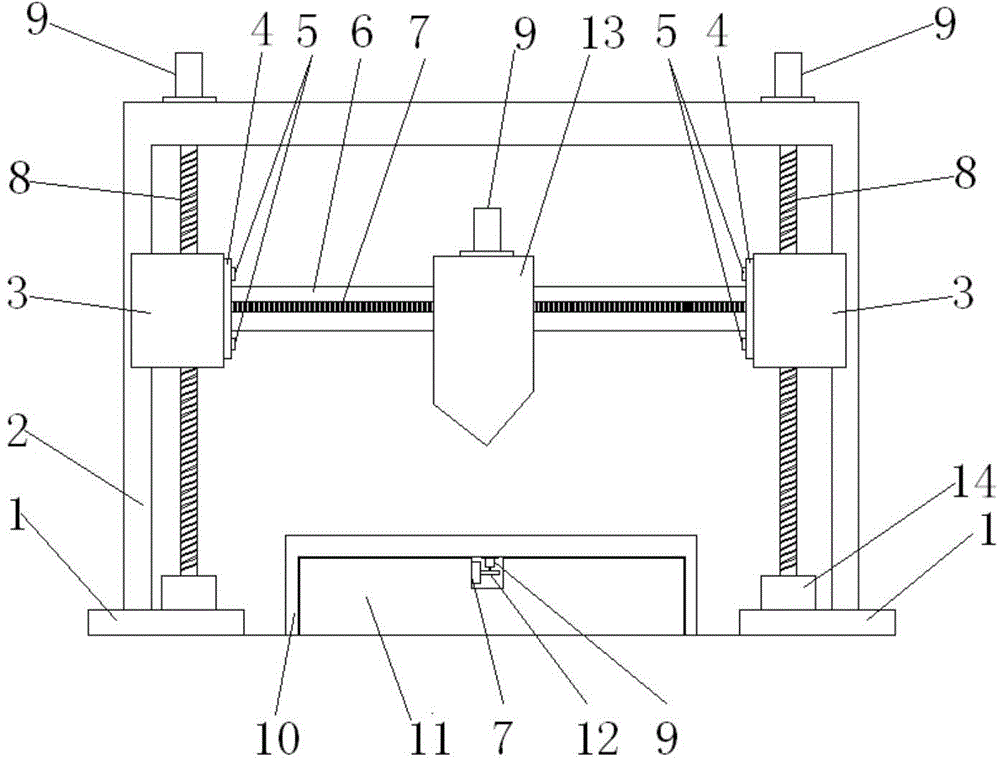

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Referring to the accompanying drawings, a three-dimensional motion mechanism for 3D printing clay includes three parts: a traverse motion mechanism, a lifting motion mechanism, and a worktable motion mechanism.

[0014] The traversing motion mechanism is composed of a mounting base B4, a screw 5, a traversing guide rail 6, a rack 7, a motor 9, and a printing head 13. The mounting base B4 is connected with the slider 3 and the traversing guide rail 6 through the screw 5, the rack 7 is fixed on the traversing guide rail 6, the slider 3 is installed on the back of the print head 13, and is slidably connected with the traversing guide rail 6, and the print head 13 motors 9 are installed on the top, and gears 12 are installed on the shaft ends to engage with racks 7 . The horizontal movement mechanism can adjust the left and right positions of the printing...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap