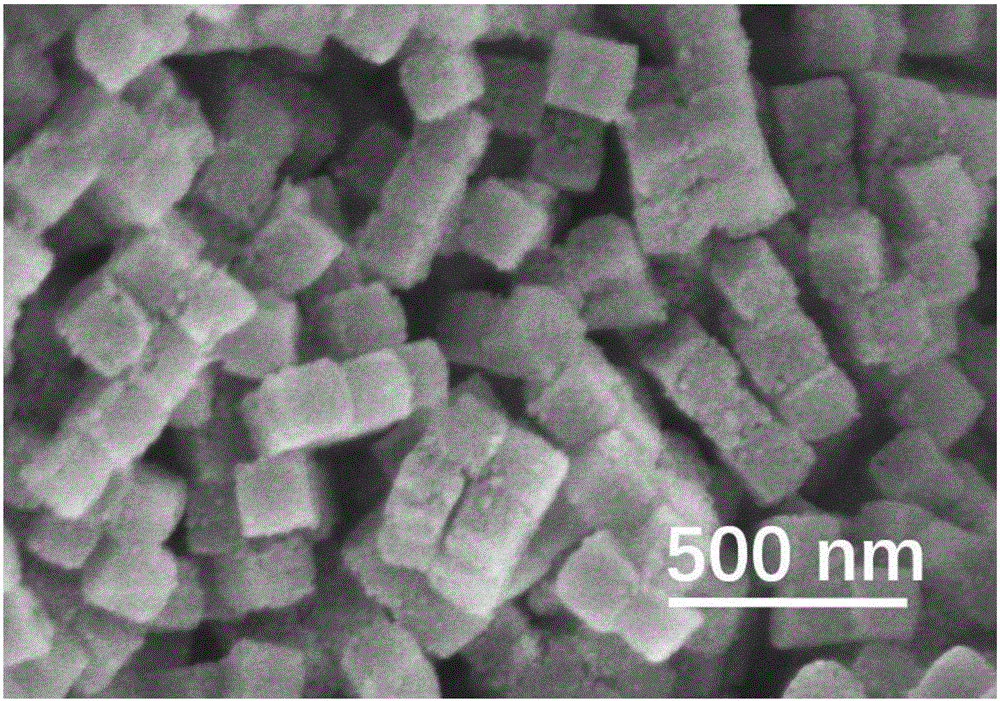

Preparation method of carbon-nitrogen-codoped NiFe2O4-Ni nanocomposite material with cubic structure

A nano-cube and composite material technology, which is applied in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of low conductivity and rate, low specific capacitance, etc., and achieves fewer synthesis steps, simple operation methods, The effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A carbon-nitrogen co-doped NiFe 2 o 4 The preparation method of / Ni nano cubic structure composite material, concrete steps are as follows:

[0036] (1) Synthesis and preparation of the precursor: Take 100ML aqueous solution, add 0.267g nickel acetate, 4g PVP, 0.1g sodium citrate and fully stir to dissolve. Take another 100ML aqueous solution and add 1.3g potassium ferricyanate solid, stir well to dissolve. Slowly add the potassium ferricyanate solution dropwise into the nickel acetate solution, stir for 30min and then place it at room temperature. After 24 hours, centrifuge, wash with water and alcohol for three times, then dry and set aside.

[0037] (2) Calcination process: Weigh a certain amount of precursor with an analytical balance, place it in a porcelain boat and put it into a tube furnace, inject nitrogen protective gas, and set a heating program. The heating rate is 1°C / min. Raise the temperature to 300°C for 2 hours and then cool down to room temperatur...

Embodiment 2

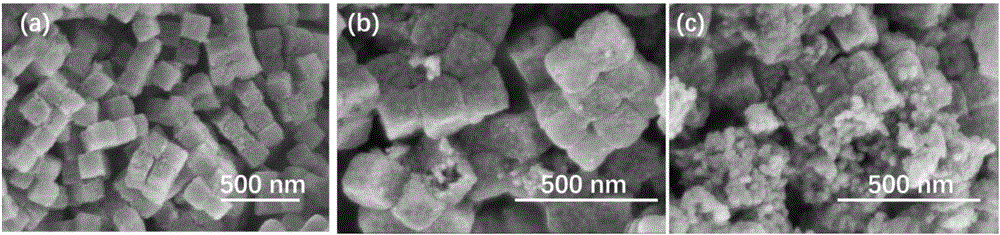

[0046] A carbon-nitrogen co-doped NiFe 2 o 4 The preparation method of / Ni nano cubic structure composite material, concrete steps are as follows:

[0047] (1) Synthesis and preparation of the precursor: Take 100ML aqueous solution, add 0.267g nickel acetate, 4g PVP, 0.1g sodium citrate and fully stir to dissolve. Take another 100ML aqueous solution and add 1.3g potassium ferricyanate solid, stir well to dissolve. Slowly add the potassium ferricyanate solution dropwise into the nickel acetate solution, stir for 30min and then place it at room temperature. After 24 hours, centrifuge, wash with water and alcohol for three times, then dry and set aside.

[0048] (2) Calcination process: Weigh a certain amount of precursor with an analytical balance, place it in a porcelain boat and put it into a tube furnace, inject nitrogen protective gas, and set a heating program. The heating rate is 1°C / min. Respectively raise the temperature to 300°C, 350°C, and 400°C for 2 hours, then ...

Embodiment 3

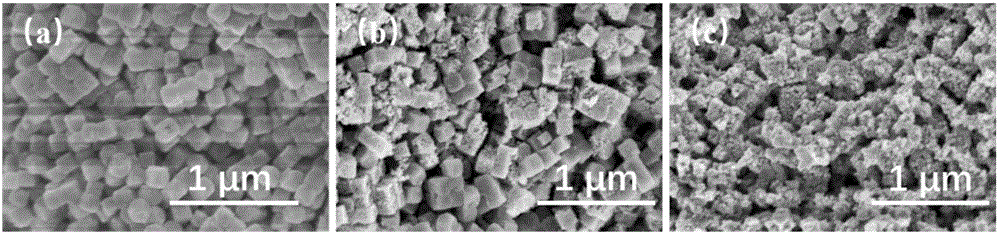

[0051] A carbon-nitrogen co-doped NiFe 2 o 4 The preparation method of / Ni nano cubic structure composite material, concrete steps are as follows:

[0052] (1) Precursor synthesis and preparation: Weigh 0.142g nickel acetate and 0.25g sodium citrate dissolved in 100ML aqueous solution to prepare solution A; weigh 0.07g potassium ferricyanate and 0.3g PVP dissolved in 100ML aqueous solution to prepare solution B . Slowly add solution B to solution A under stirring conditions, continue stirring for 30 min after the dropwise addition, stop stirring, and let stand at room temperature for 20 h. Centrifuge, wash with water, and wash with ethanol three times each, then dry and set aside.

[0053] (2) Calcination process: Weigh a certain amount of precursor with an analytical balance, place it in a porcelain boat and put it into a tube furnace, inject nitrogen protective gas, and set a heating program. The heating rates were 0.5°C / min, 1°C / min, and 5°C / min, respectively. Raise th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com