A batch cement pouring method for large sculptures

A technology of cement and sculpture, which is applied in the field of architectural gardens, can solve the problems of inability to meet the strength requirements of large sculptures, high artistic taste requirements of operators, and high labor costs, and achieve complex and beautiful appearances, uniform and beautiful appearances, and low labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

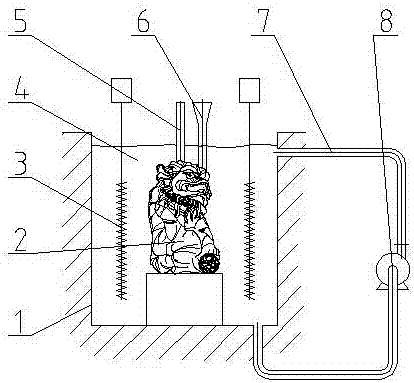

[0019] like figure 1 Shown, be used for pouring equipment of the present invention and comprise pouring tank 1, steel bar frame clamping, agitator 3, cement pump 8, steel bar frame clamping mold is fixed in pouring tank 1, and steel bar frame clamping is to make with steel bar and mold 2 skeletons with similar shapes, the size of the skeleton is smaller than the size of the mold 2, the size of the pouring groove 1 is, the length and width are 1.5-2 times the length and width of the casting mold 2, and 1.5 times the height, and the pouring groove 1 is provided with advanced At the outlet, a cement pump 8 is correspondingly connected with the pipeline 7 for the inlet and outlet of the pouring trough 1, and 3-4 low-speed agitators 3 are arranged in the pouring trough 1.

[0020] Mold making:

[0021] Make a plaster sample that needs to be cast or take a sample directly on the existing sculpture, and spray it on the sample with plastic or rubber. The plastic or rubber can be PET ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com