Reforming reactor fan-shaped barrels capable of reducing catalyst leakage

The technology of reforming reactor and fan-shaped cylinder is applied in the direction of catalytic reforming of naphtha, which can solve the problems of long-term operation hidden danger, damage and different expansion of the device, so as to eliminate catalyst leakage, reduce production cost, The effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

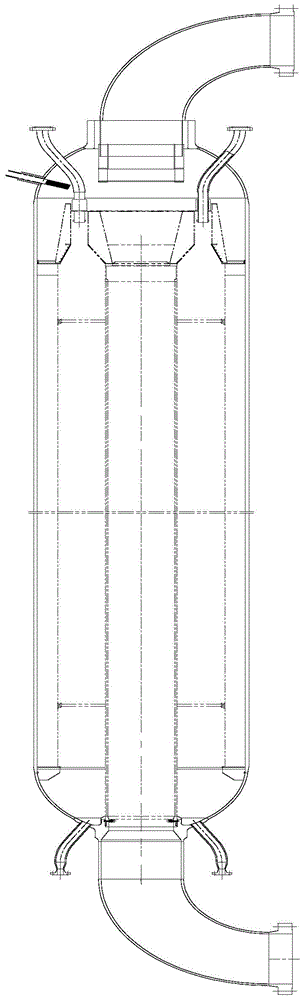

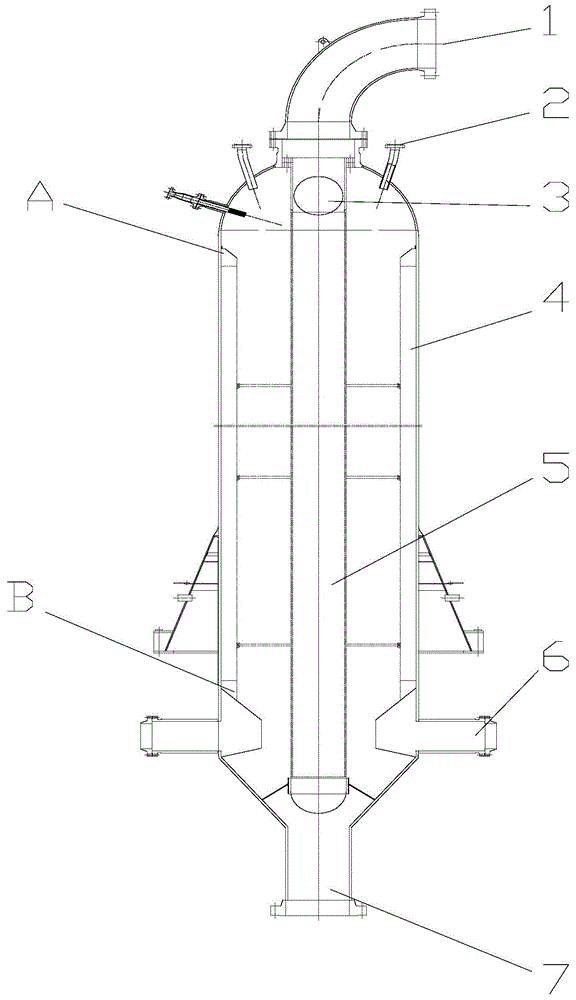

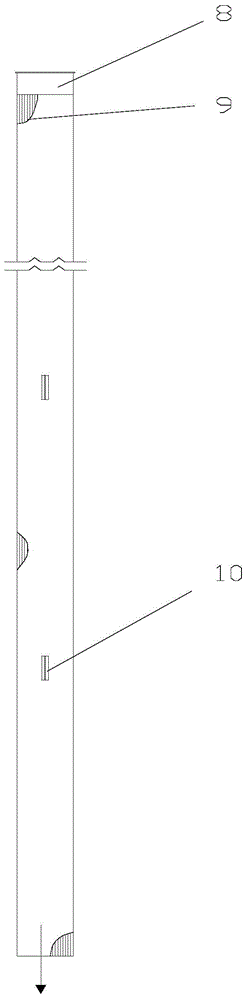

[0019] use image 3 , Figure 4 The fan-shaped cylinder of the reforming reactor shown is a Johnson mesh fan-shaped cylinder, and is used figure 2 The structure is installed in the reforming reactor. The upper part of the fan-shaped tube 4 of the reforming reactor is at the top of the reactor, and is basically flush with the weld seam line of the reactor head. The top of the fan-shaped tube is sealed, and the top smooth pipe is wedge-shaped. The angle between the wedge-shaped slope and the back of the fan-shaped tube is 45 degrees. The fan-shaped cylinder is evenly distributed along the inner wall of the reactor, and 3 to 5 sets of support frames 10 are used to make it close to the inner wall of the reactor, which reduces the wear of the catalyst on the fan-shaped cylinder; the opening at the bottom of the fan-shaped cylinder is connected with the manifold 11 at the bottom of the reactor, The way of connection is that there is an annular groove at the bottom of the fan-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com