A variable cross-section hybrid vault reticulated shell for storage tanks

A variable cross-section and mixed-type technology, applied to the roof, building type, building components, etc., can solve the problems that cannot reflect the design principles of the vaulted reticulated shell tank, the adverse effects of the lower tank body, and the uneven stress of the reticulated shell. Achieve easy identification and classification, ensure safety and economy, and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

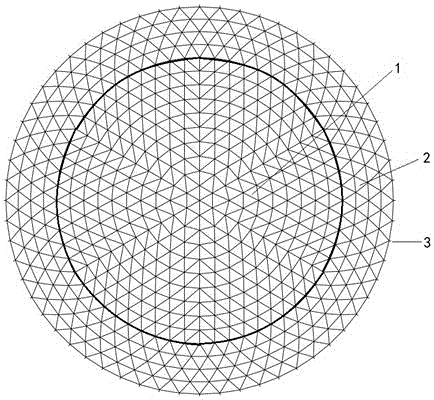

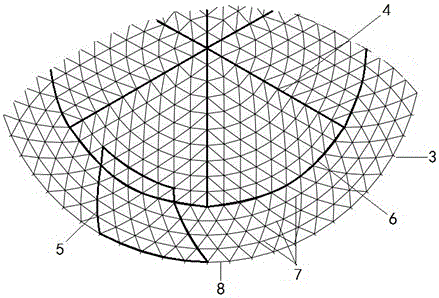

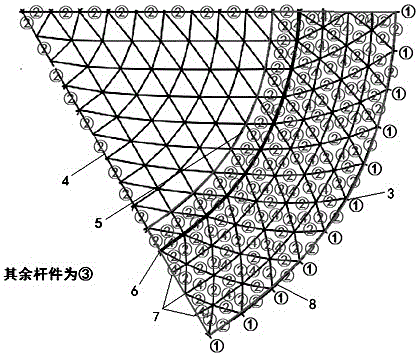

[0030] A hybrid vault reticulated shell storage tank with a volume of 30,000 m3 has a span of 46m and a height of 6.16m. The radius of the spherical reticulated shell is 46m. The entire reticulated shell has 10 rings, of which the Kaivit type reticulated shell occupies the middle part. 8 rings, 2 rings in the outermost ring are joint square reticulated shells. A 3mm steel skin is laid on the top, converted into a surface load of 500Pa, which is part of the fixed load; the additional load is 1200Pa.

[0031] Use the general finite element software ANSYS to establish the finite element model of the vaulted reticulated shell storage tank, such as Figure 5 shown. Among them, the space beam unit BEAM188 is used for the rod, and the shell unit SHELL181 is used for the tank wall. Under the premise of meeting the requirements of the strength, stiffness and overall stability of the reticulated shell, the rod specification uniformly adopts WH150×100×5×8mm, that is, the H-shaped steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com