Tower crane construction technology used for super high-rise building steel structure

A construction technology and super-high-rise technology, applied in the direction of building structure, building material processing, construction, etc., can solve the problems of engineering efficiency, quality and cost with imperfect technology, and achieve reasonable function configuration and layout, correct calculation, Reasonable effect of process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

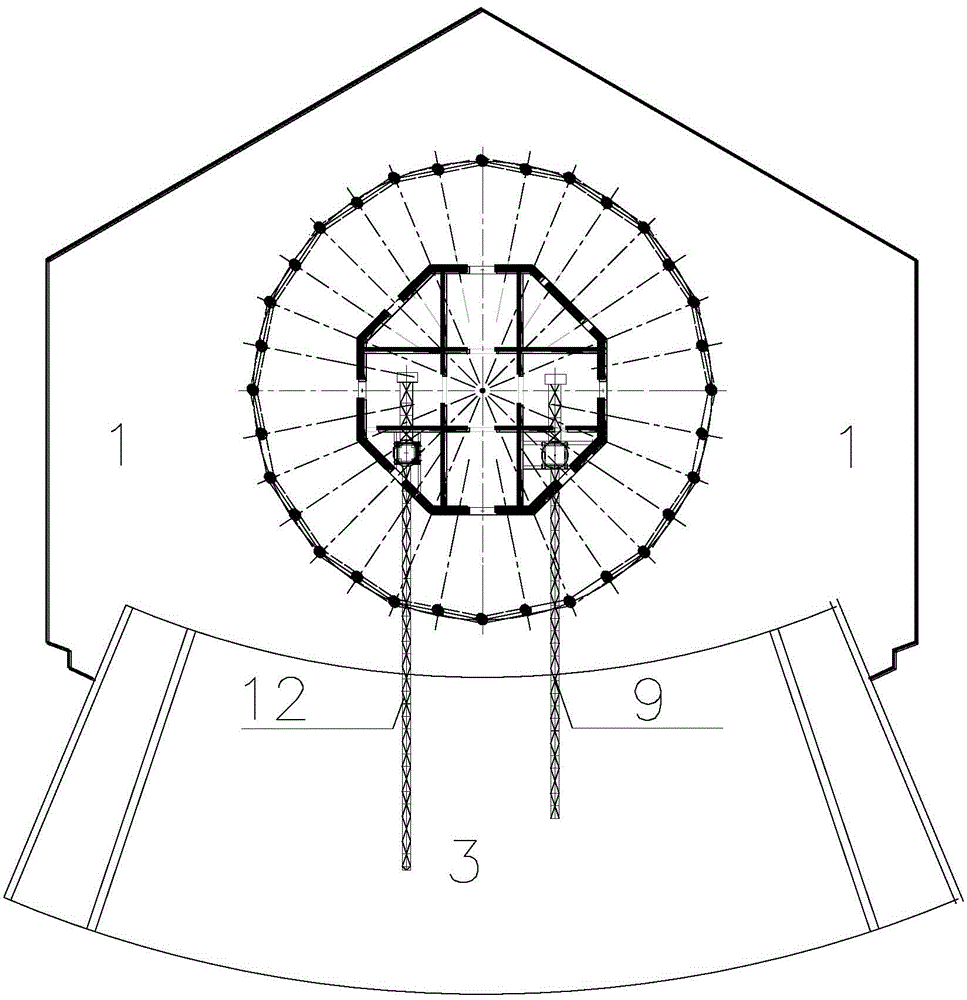

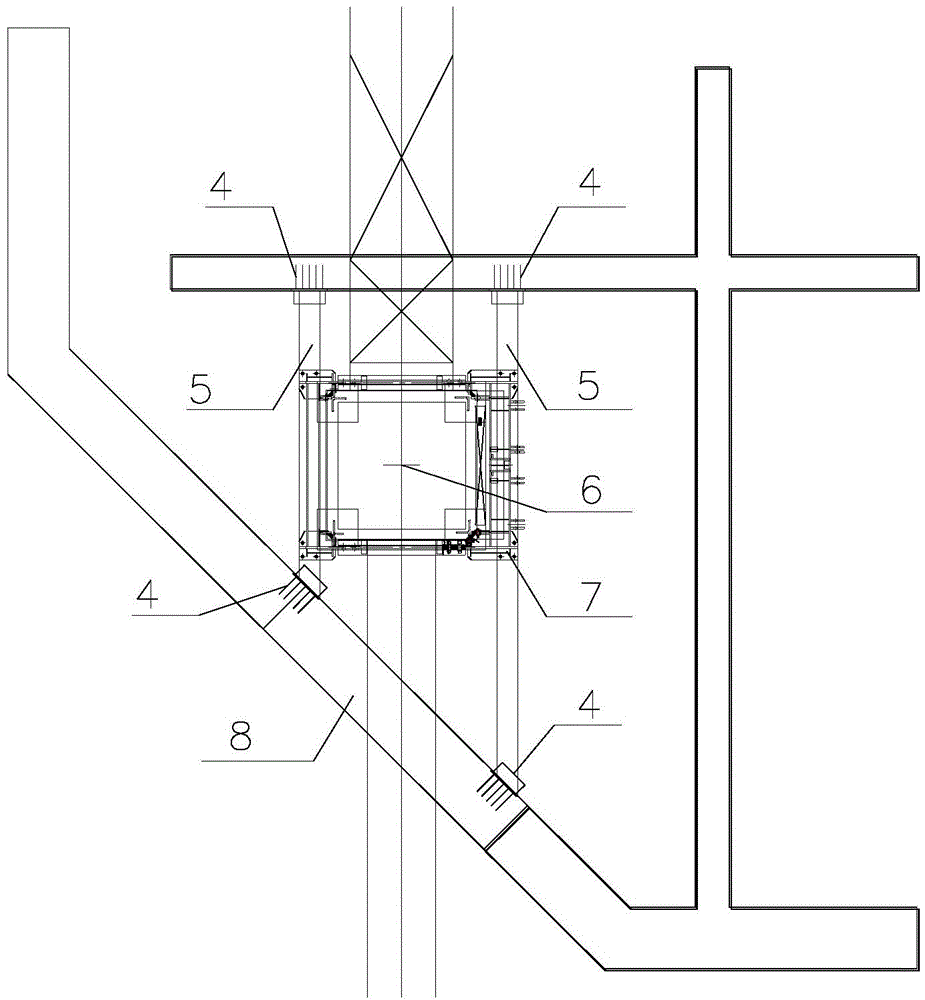

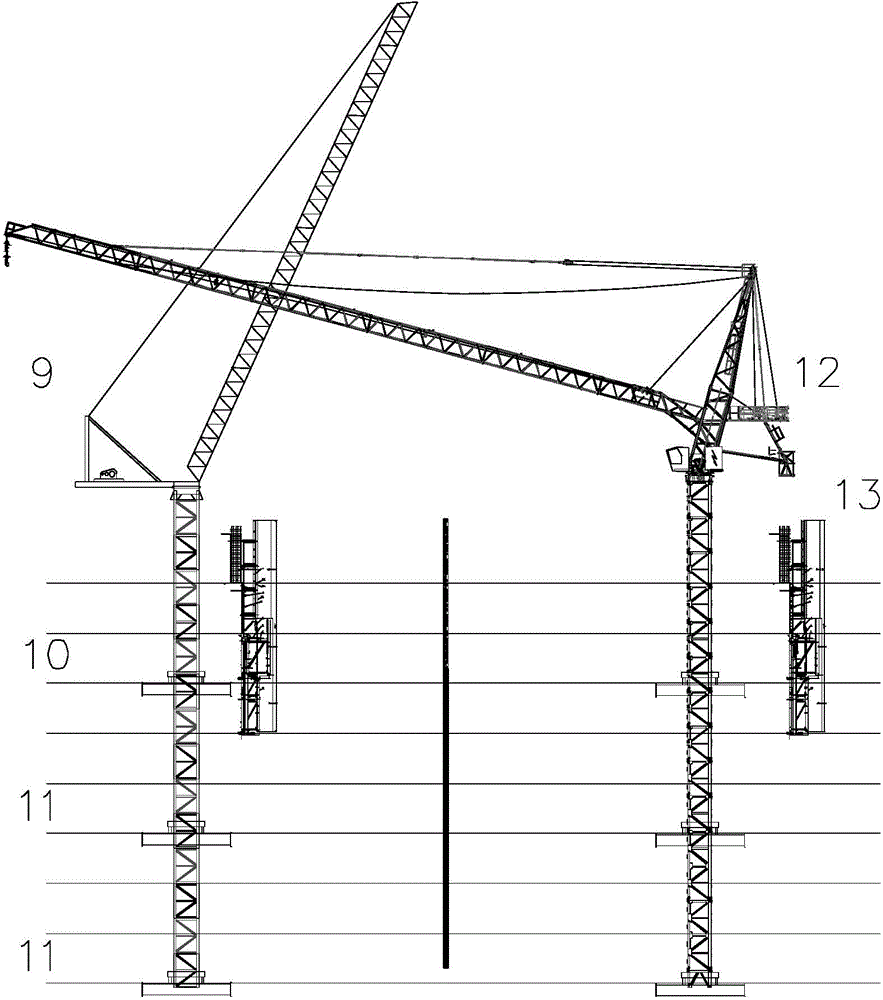

[0028] Now take the drafting of a project as an example to illustrate. The main building parameters of the example are: the main building has 60 floors above ground, 4 floors underground, the total building height is 280 meters, and the total construction area is about 180,000 square meters. The main building adopts an outer frame and inner tube structure system. The plane of the core tube is octagonal, which is a reinforced concrete structure, and steel columns are inserted inside; the outer frame is hexagonal, and the outer frame columns are steel concrete columns, and the outer frame floor is steel beams. , Composite floor slab of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com