Tandem type upright ladder for maintaining high-voltage lines

A technology for high-voltage lines and ladder columns, applied in overhead lines/cable equipment, ladders, buildings, etc., can solve problems such as high-voltage line instability, maintenance accidents, and unfavorable environmental protection, and achieve the effect of convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

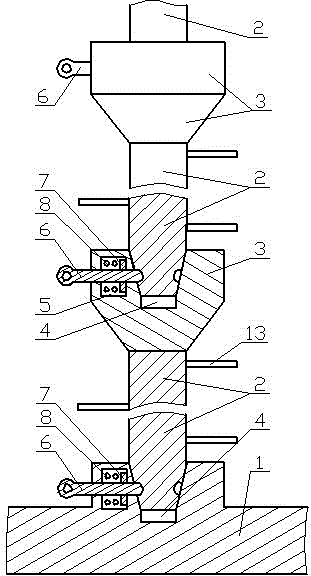

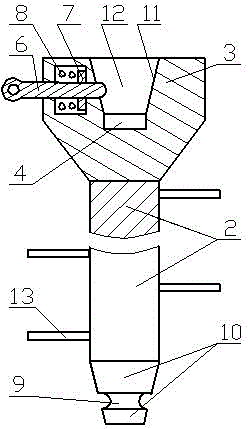

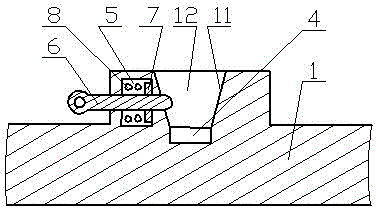

[0044] The series-connected upright high-voltage line maintenance ladder of the present invention mainly includes a chassis 1, a ladder column, a lock hole 5, a brake pin 6, a lock spring 8, a fixed plate 7, a lock groove 9, an outer cone surface 10, and an inner cone hole 12. Inner cone surface 11;

[0045] The protruding circle in the middle of the chassis 1 has an inner cone hole 12, a clearance groove 4 is provided under the inner cone hole 12, and a lock hole 5 is provided between the convex circle surface and the inner cone hole 12; The surface of the column body is fixed with a folding foot 13 that can be folded to one end of the connecting head 3 of the ladder column body. There is an outer cone surface 10 at one end of the ladder column body and a connecting head 3 at the other end. There is an inner taper hole 12 inside, a gap groove 4 inside the inner taper hole 12, and a lock hole 5 between the connecting head 3 and the inner taper hole 12; the lock hole 5 is horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com