Air compression energy storage and thermal power plant-based joint control system and method

A technology of compressed air energy storage and joint control, which is applied in heating systems, hot water central heating systems, heating methods, etc., can solve the problems of low wind energy absorption capacity of the power grid, reduce start-up and stop costs, reduce output, Effect of reducing heating output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention provides a combined control system and method based on compressed air energy storage and thermal power plants in the case of heating in winter. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

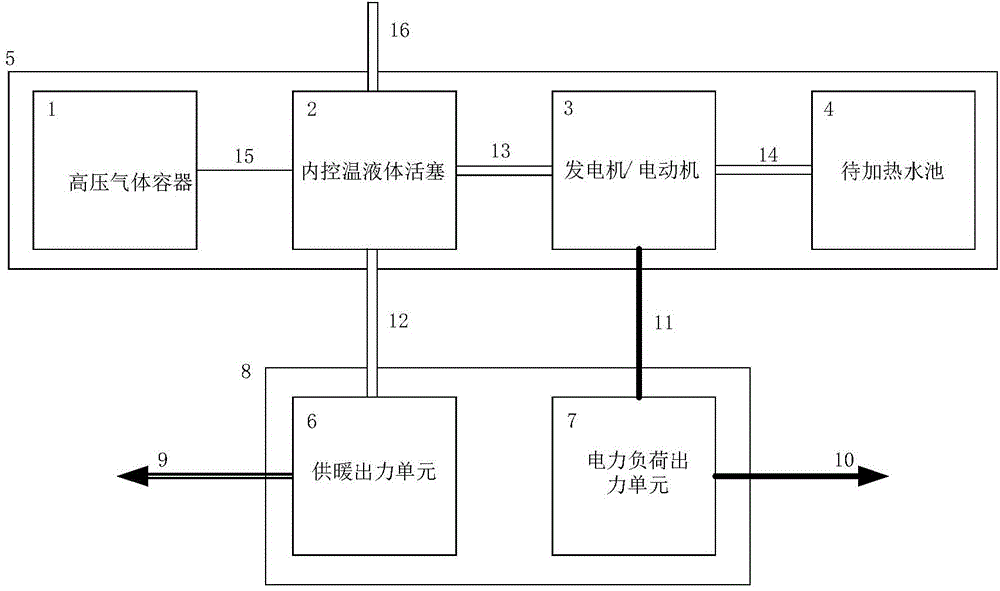

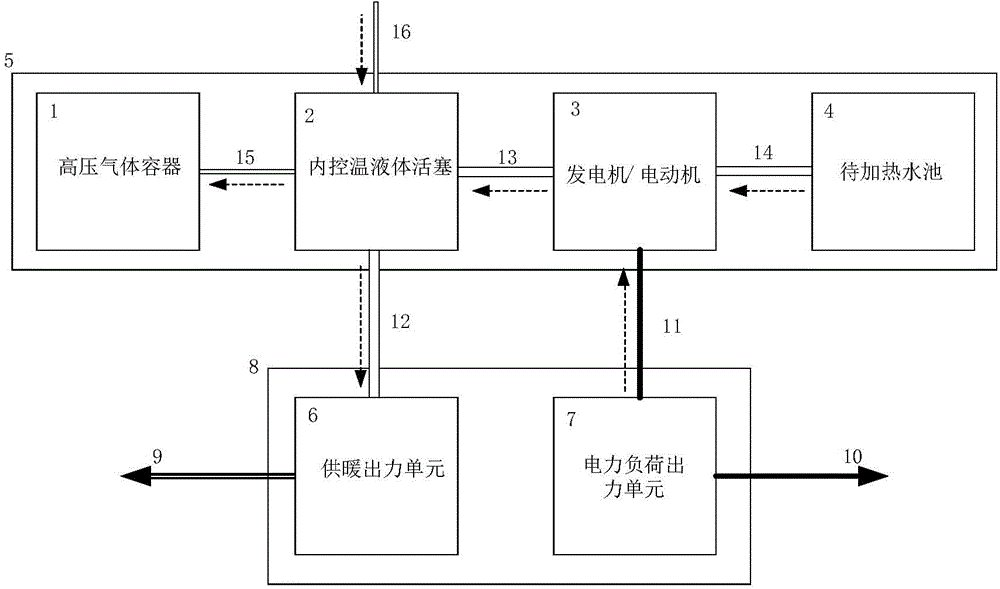

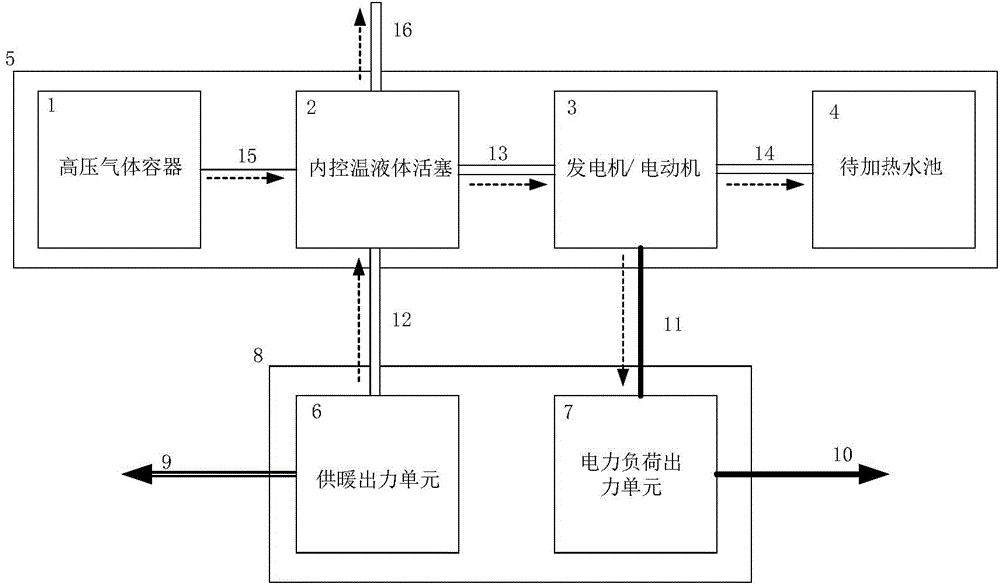

[0026] figure 1 It is a schematic diagram of system connection of a control scheme of the present invention.

[0027] The system consists of a liquid temperature-controlled compressed air energy storage device 5 and a thermal power plant 8 .

[0028] The liquid temperature-controlled compressed air energy storage device 5 is composed of a high-pressure gas container 1, an internal temperature-controlled liquid piston 2, a generator / motor 3, and a pool to be heated 4; wherein the high-pressure gas container 1 and the internal temperature-controlled liquid piston 2 pass through the high-pressure gas pipeline 15 connection, the internal temperature control liquid piston 2 and the gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com