Shock-absorption buffer shaft and application

A buffer shaft, input shaft technology, applied in the direction of couplings, elastic couplings, vehicle parts, etc., can solve the problem of not being able to withstand two-way action, vibration damping and shock resistance, smooth torque output, energy-absorbing materials that absorb less impact energy, Secondary impact and other problems, to achieve the effect of reducing impact stress, smooth torque output, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

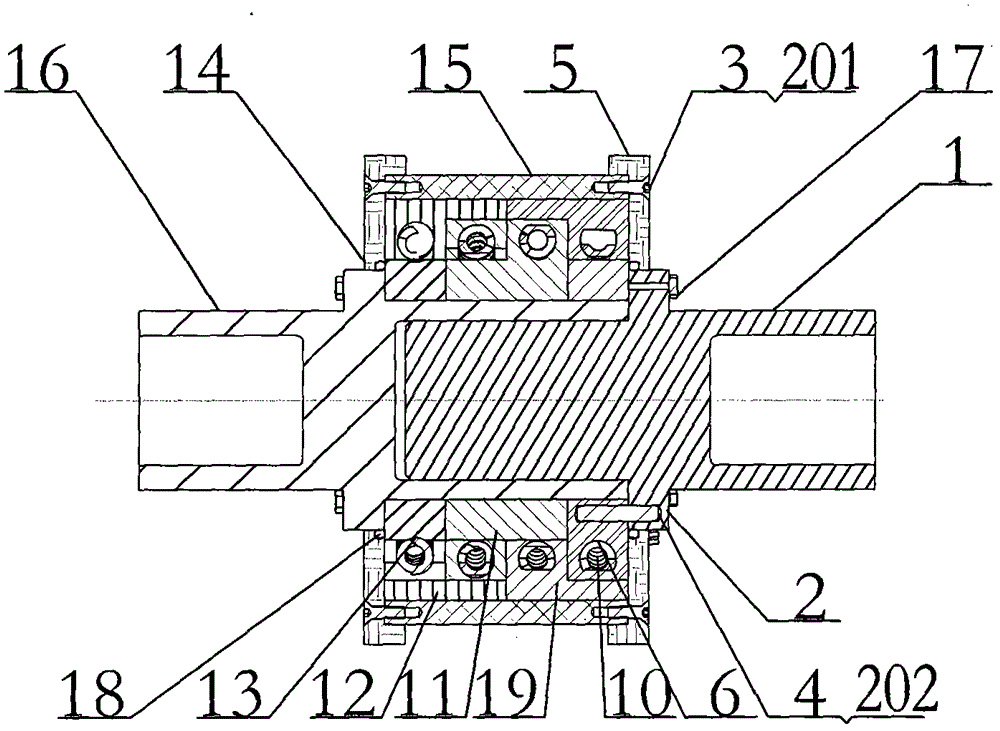

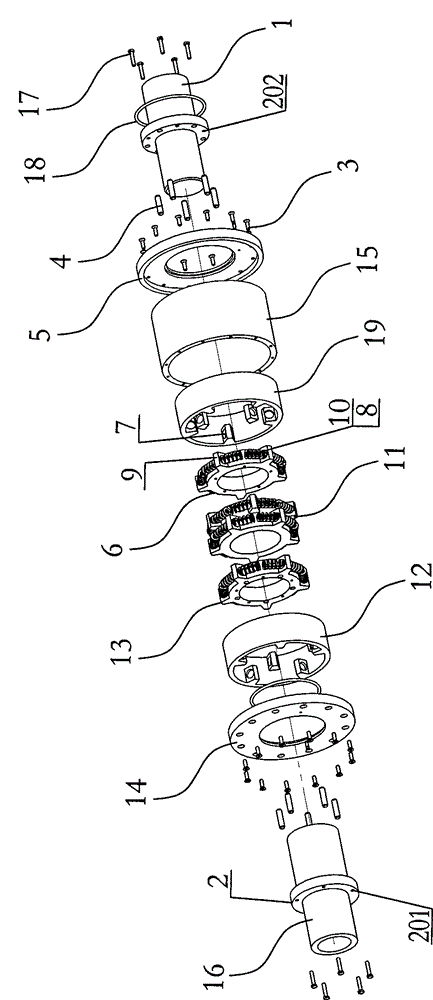

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

[0027] figure 1 , 2 As shown: a shock absorbing buffer shaft includes an input shaft 1, a fastening bolt 3, a force transmission pin 4, an input end cover 5, an input tooth plate 6, a spring 10, an input tooth cover 19, a double tooth plate 11, an output tooth set 12, Output tooth plate 13, output end cover 14, outer casing 15, output shaft 16, limit screw 17 and O-shaped sealing ring 18.

[0028]Both the input shaft 1 and the output shaft 16 are provided with a ring of flange flanges 2, and a plurality of limit screw holes 201 are evenly opened on the two flange flanges 2, and the two opposite inner end surfaces of the two flange flanges are uniformly arranged. There are a plurality of force transmission counterbores 202, and the plurality of force transmission counterbores 202 of the input shaft 1 are connected to the input crankset 6 through the force transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com