Air damper

An air shock absorber and air groove technology, used in the field of auto parts, can solve the problems of unsatisfactory shock absorption effect, complex production process, slow recovery speed, etc., and achieve good shock absorption effect, high safety and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

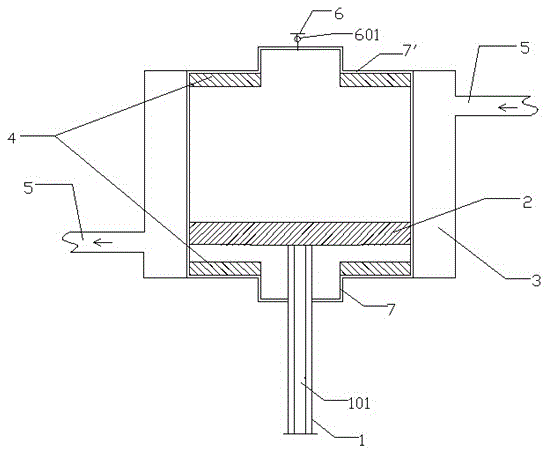

[0014] Such as figure 1 and figure 2 As shown: an air shock absorber, including a cylinder body, the two ends of the cylinder body are fixed on the gland I7 and gland II7', and the gland I7 and gland II7' are located on one side of the cylinder body. A layer of elastic parts 4 is fixed, and a piston 2 that reciprocates along the wall of the cylinder body is arranged between the two layers of elastic parts 4. The piston 2 is fixed on one end of the piston rod 1, and the other end of the piston rod 1 extends to the outside of the gland Ⅰ7. The rod 1 is provided with a plurality of air grooves 101 fixed together with it, and the other side of the gland II 7' is fixed with an air inlet and outlet 6, and the air inlet and outlet 6 is provided with a filter device 601 for filtering air, and the outer casing of the cylinder body is connected with Cooling barrel 3, the inlet and outlet of the cooling barrel 3 communicate with the automobile cooling circulation system.

[0015] Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com