Valve ball conical surface locking structure of flushing-resistant eccentric ball valve

A technology of locking structure and eccentric ball, which is applied in the direction of valve device, cock including cut-off device, engine components, etc., can solve the problems that affect the valve cut-off performance, and the spherical surface and the valve seat are difficult to fit tightly, so as to avoid serious deformation and Difficult to process accurately, strong erosion resistance, and the effect of improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

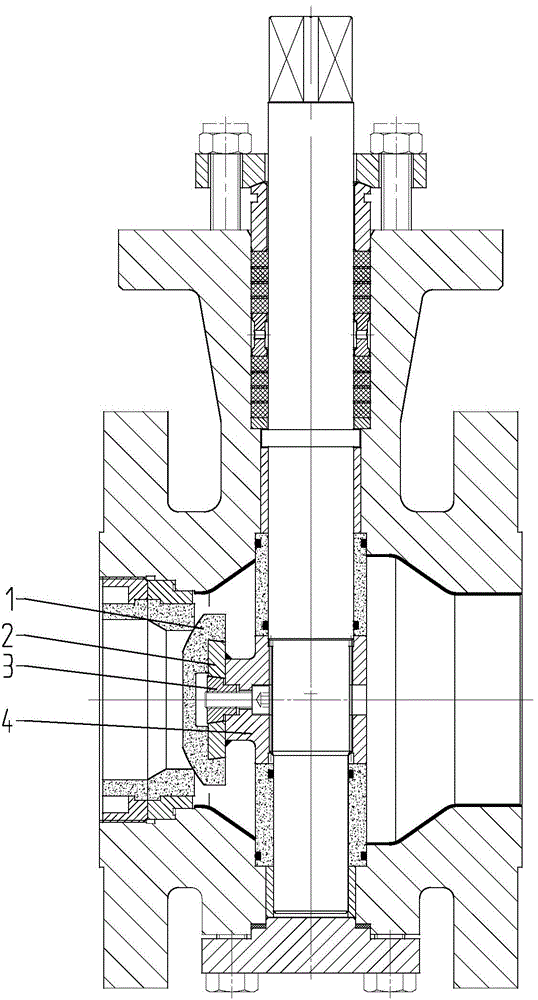

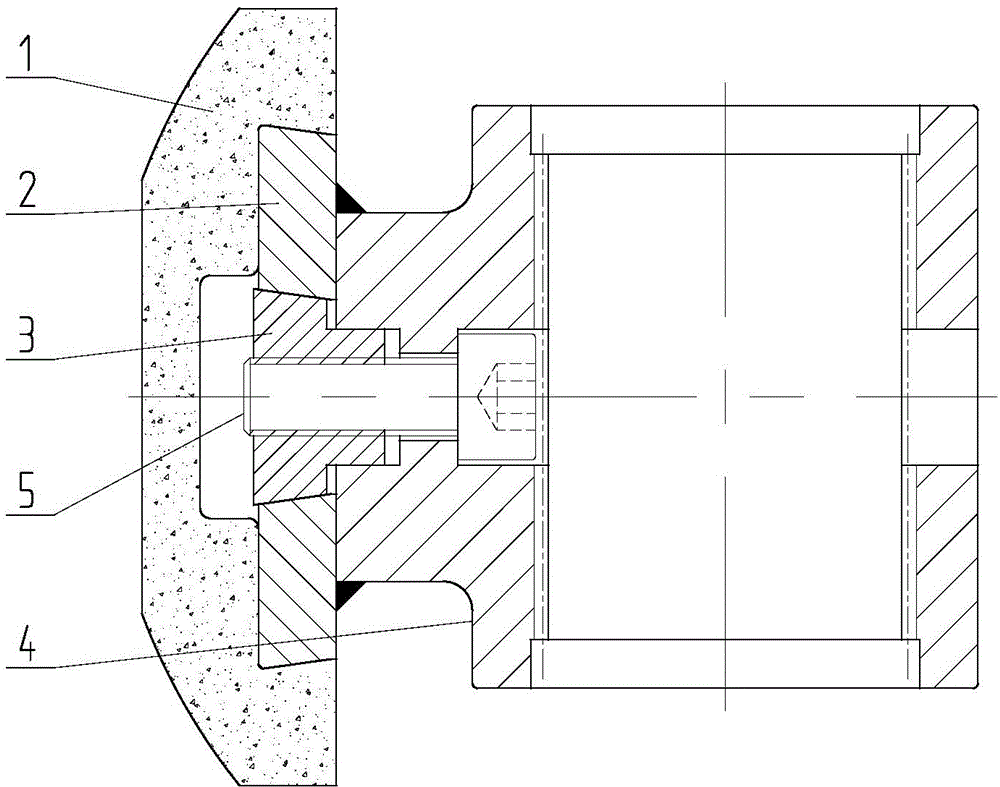

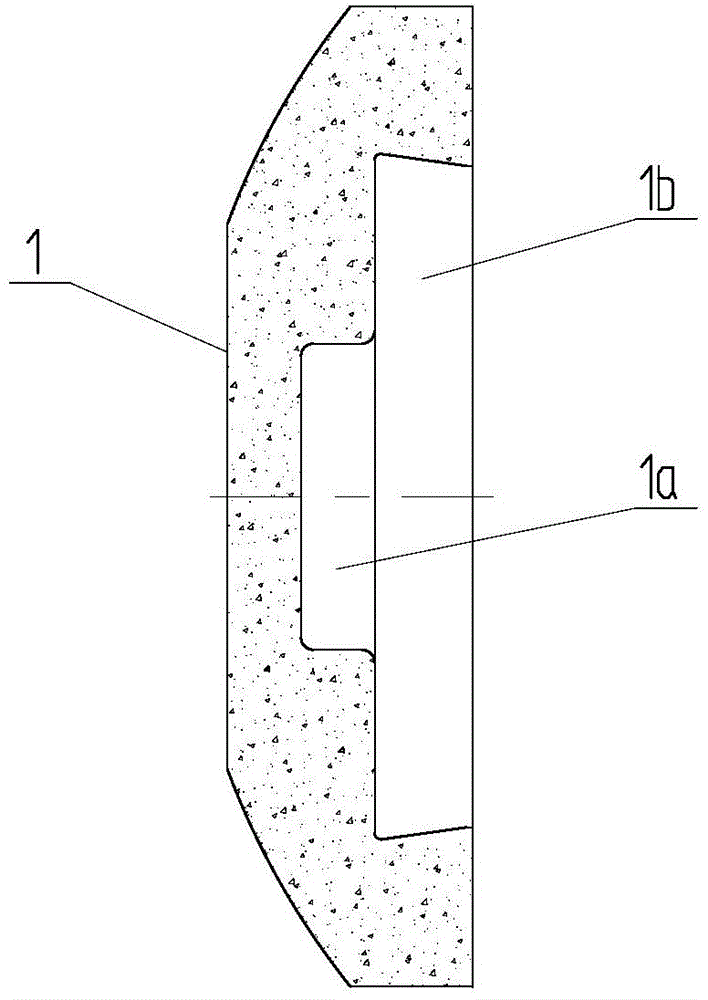

[0024] Such as Figure 1~7 As shown, the present invention mainly includes an erosion-resistant spherical surface 1, an expansion ring 2, a locking block 3, and an eccentric ball handle 4. A positioning hole 4a is provided on one side of the eccentric ball handle 4, and the locking block is connected with a screw 5 in the positioning hole 4a. 3.

[0025] The inner front end surface of the positioning hole 4 a is the positioning surface of the locking block 3 , and the inner rear end surface of the positioning hole 4 a is the positioning surface of the screw 5 .

[0026] Such as Figure 7 As shown, the side of the eccentric ball handle 4 facing away from the positioning hole 4a is provided with a counterbore 4b. When the screw 5 is installed, it first passes through the counterbore 4b and then enters the positioning hole 4a.

[0027] Such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com