Modified polypropylene and polyethylene composite pipe with high performance

A polyethylene composite pipe, high-density polyethylene technology, applied in rigid pipes, pipes, pipeline protection and other directions, can solve the problems of short service life, polyethylene pipe failure, easy wear, etc., to improve wear resistance and prolong use. Life and wear reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

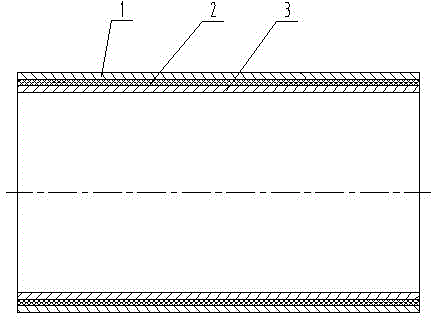

[0016] The high-performance modified polypropylene and polyethylene composite pipe shown in the accompanying drawings has a three-layer composite structure, with polypropylene layer 1, metal skeleton layer 2, high-density polyethylene, and nanocomposite layer 3 in sequence from outside to inside.

[0017] The metal skeleton layer 2 is a mesh skeleton structure formed by spirally winding high-strength steel wires left and right. In this embodiment, the high-strength steel wires of the metal skeleton layer 2 are high-strength copper-coated steel wires.

[0018] The polypropylene layer 1 is a polypropylene pipe extruded from a modified polypropylene material.

[0019] The high-density polyethylene and nanocomposite layer 3 is compounded by adding nanoparticles to high-density polyethylene, and its thickness is 1.0-2.0 mm. In this embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com