Medium board and manufacturing method thereof

一种制作方法、中介的技术,应用在中介板及其制作领域,能够解决制作方法复杂等问题,达到避免热应力生成的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

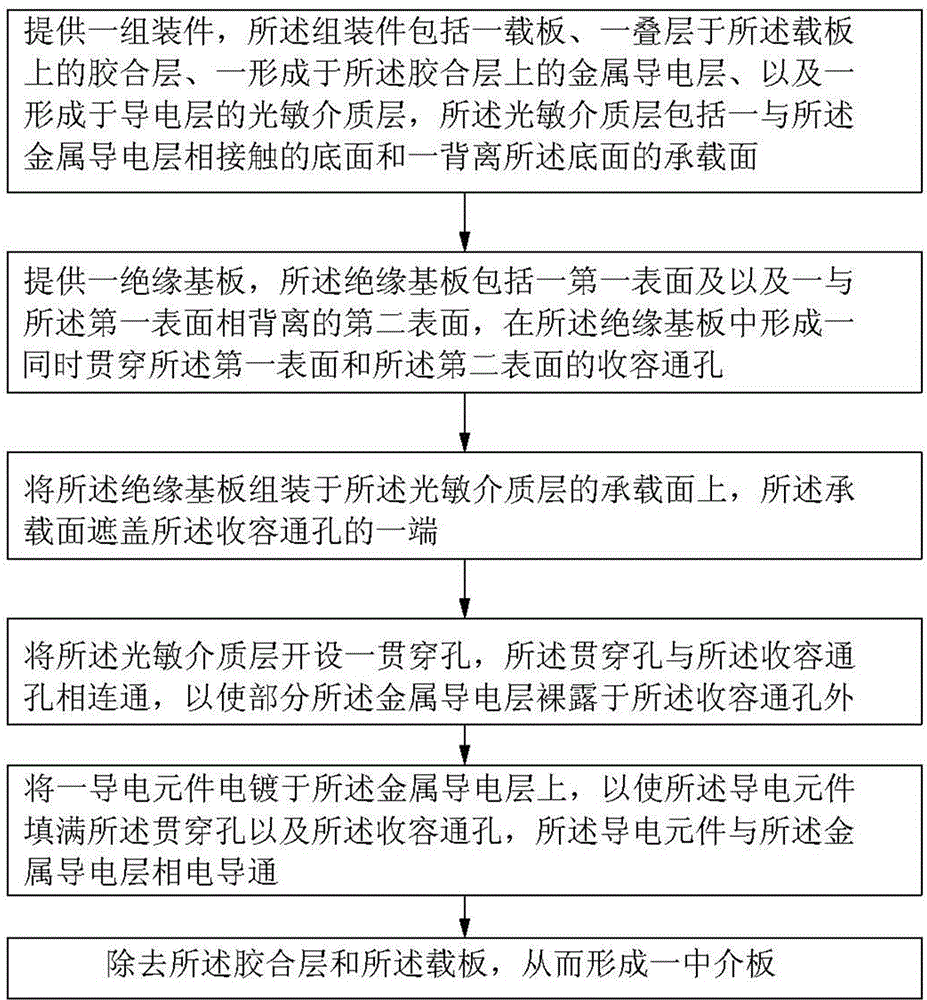

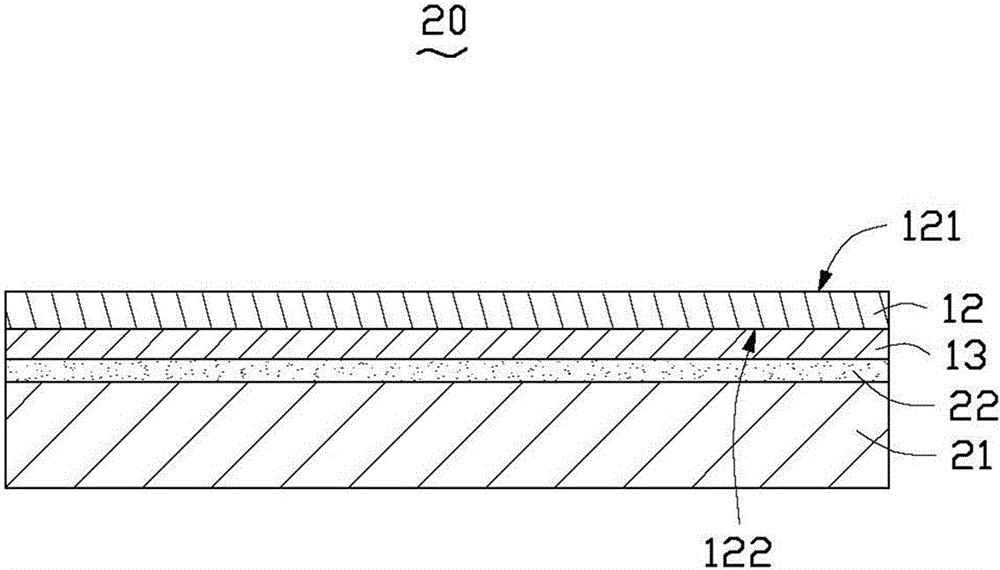

[0020] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

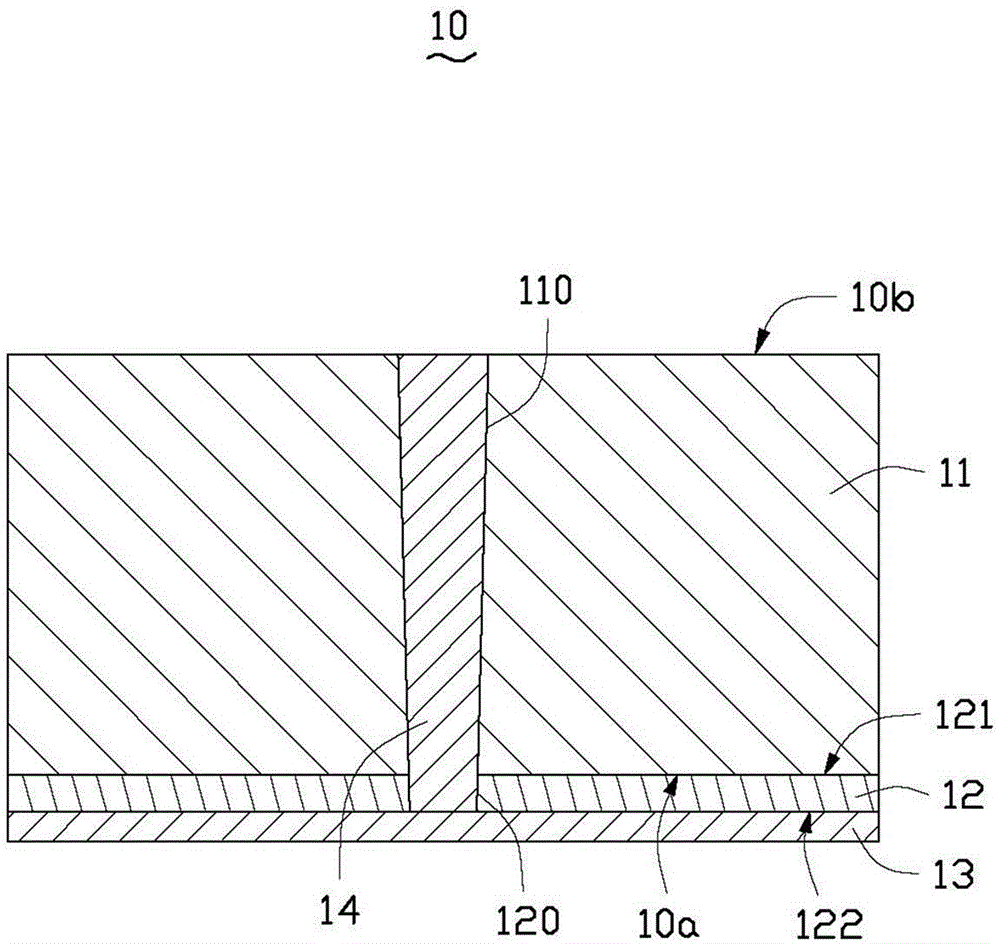

[0021] see figure 1 , the interposer 10 provided by the embodiment of the present invention includes an insulating substrate 11 , a photosensitive dielectric layer 12 , a metal conductive layer 13 and a conductive element 14 .

[0022] The insulating substrate 11 includes a first surface 10a and a second surface 10b away from the first surface 10a. The insulating substrate 11 can be made of thermosetting resins such as phenolic resin, epoxy resin, polyimide, etc., or thermoplastic resins such as polyethylene, polypropylene, polyvinyl chloride, or glass or ceramics. . In this embodiment, the insulating substrate 11 is made of glass. The insulating substrate 11 defines a receiving through hole 110 penetrating through the first surface 10 a and the second surface 10 b simultaneously.

[0023] The photosensitive medium layer 12 is formed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com