sealed battery

A sealed, battery technology, used in batteries, battery pack parts, circuits, etc., can solve the problems of inability to process, increase material costs, processing costs, and high manufacturing costs, achieve high laser welding strength, reduce manufacturing costs, and reduce manufacturing costs. The effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

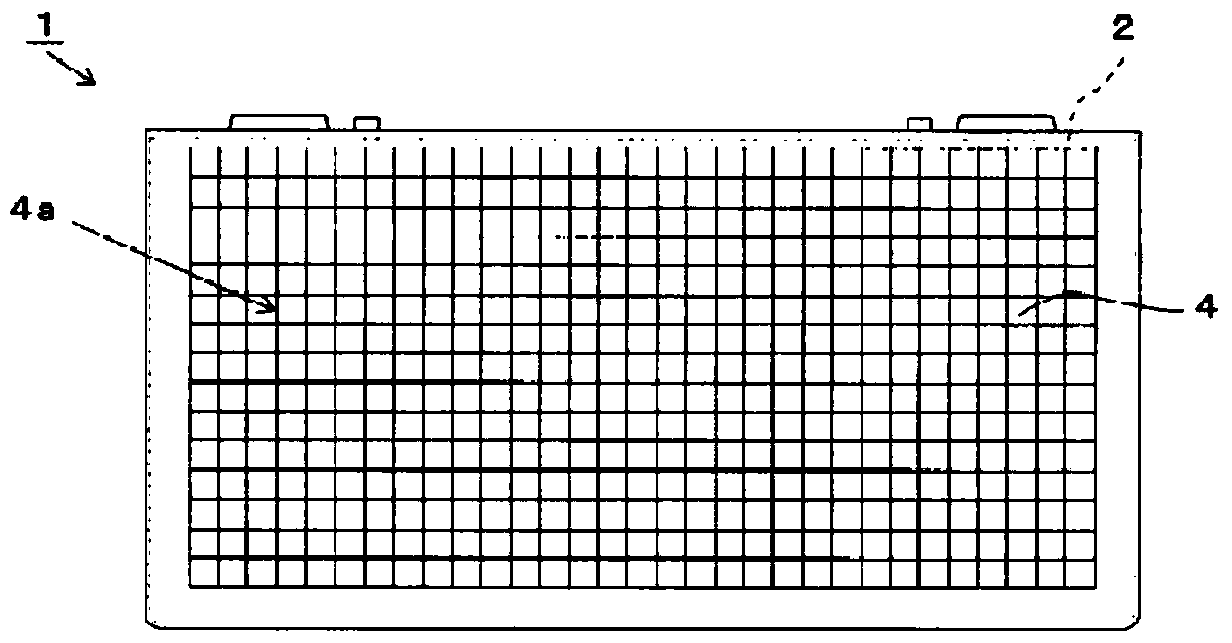

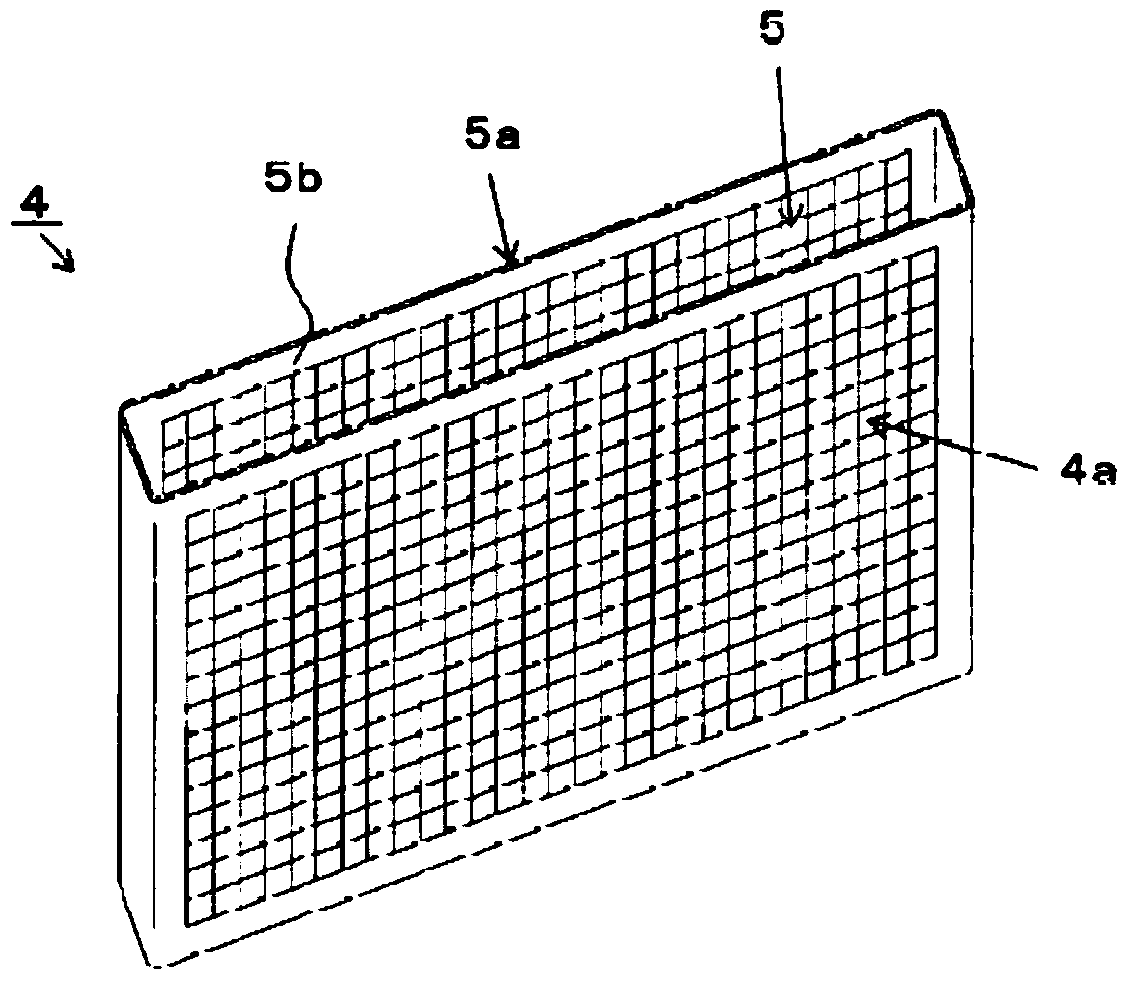

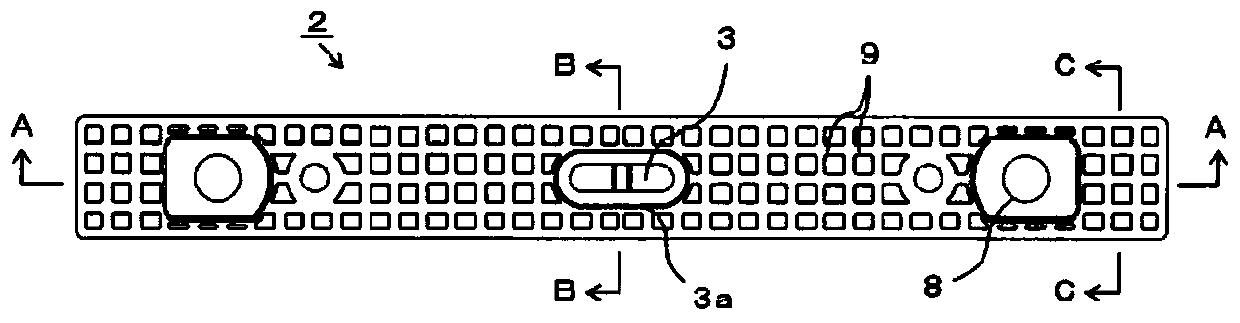

[0063] use Figure 1 to Figure 13 A sealed battery 1 according to one embodiment of the present invention will be described. figure 1 It is a front view of a sealed battery 1. The cover plate 2 is fitted into the opening 5 on the plane side of the case main body 4 that accommodates power generating elements such as electrolyte, wound electrode body, and separator, and along the cover plate 2 The peripheral edge 5a of the opening portion 5 and the opening portion 5 are laser welded, and the opening portion 5 is sealed by the cover plate 2 .

[0064] The casing main body 4 is a stretched aluminum alloy plate or a thin stainless steel plate. Here, it is an aluminum alloy plate, and the cylindrical shape with a bottom is formed into an elongated rectangular parallelepiped. The flat side of the bottomed square cylindrical casing body 4 is opened, and a rectangular opening 5 is formed inside the cylindrical inner wall surface. In addition, on the plane and the back of the case ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com