Reciprocating compressor and method for driving same

A compressor, reciprocating technology, applied in the direction of machines/engines, liquid variable capacity machinery, mechanical equipment, etc., can solve the problems of increasing the vibration noise of the compressor, wear, emission noise and the vibration can not be effectively offset, etc. The effect of reducing vibration noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0096] Meanwhile, the previous embodiment shows that the filter unit is provided on the passage of the refrigerant gas to filter foreign matter before the refrigerant gas is introduced into the air hole. However, these embodiments show that when the compressor is continuously operated for a predetermined period, the cylinder is vibrated periodically to remove foreign matter stuck in the air hole of the cylinder, thereby preventing clogging of the air hole in advance.

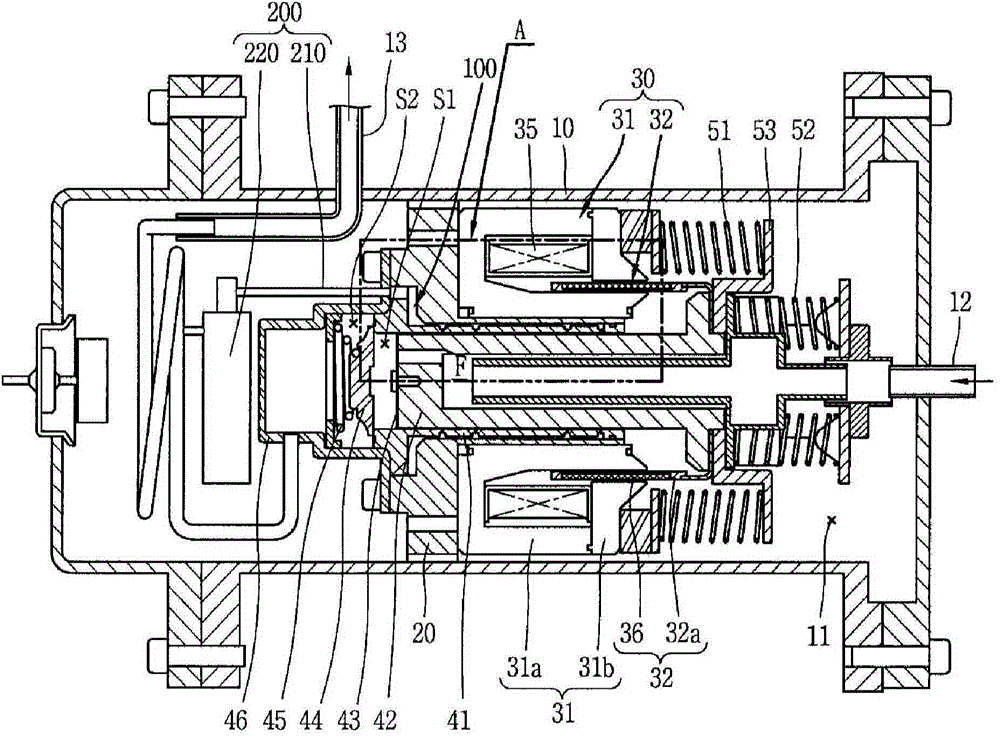

[0097] Figure 12 is a longitudinal sectional view showing a main part of another embodiment of a fluid bearing for a reciprocating compressor according to the present invention, Figure 13 is shown based on Figure 12 A schematic diagram of the foreign matter removal structure of the compressor controller, and Figure 14 is shown based on Figure 13 A block diagram of the foreign body removal process.

[0098] For example, if Figure 12 to Figure 14 As shown in , the operation duration t1 of the compressor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com