Unit and casing with a cooling jacket

A technology of cooling jacket and shell, applied in the direction of casing/cover/support, electromechanical device, electrical components, etc., can solve the problem of processing labor and other problems, and achieve the effect of eliminating reprocessing, efficient heat transfer, and high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

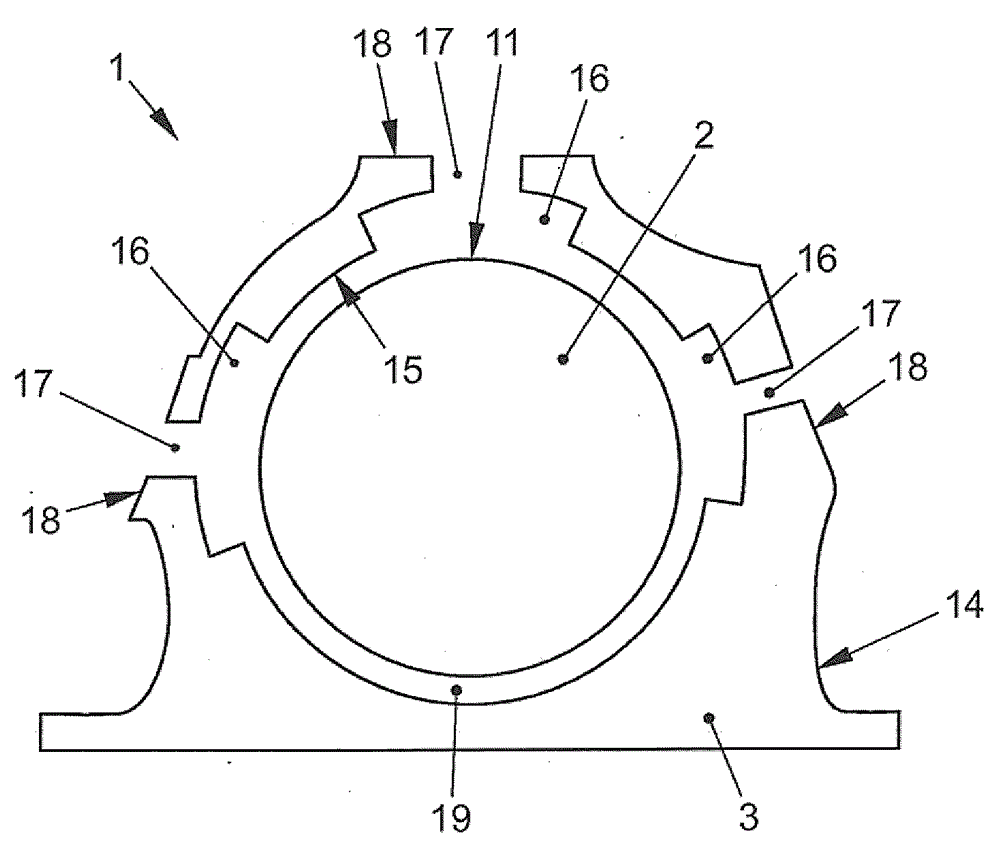

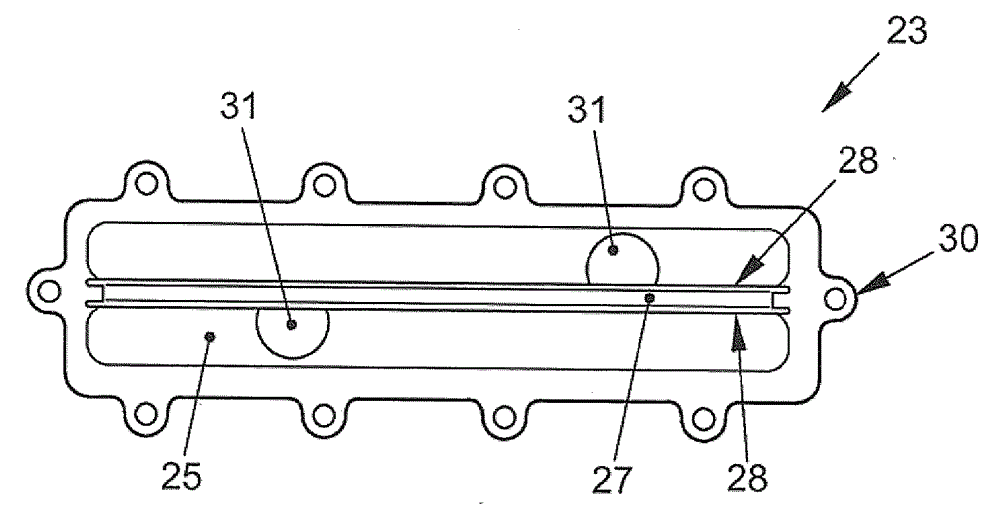

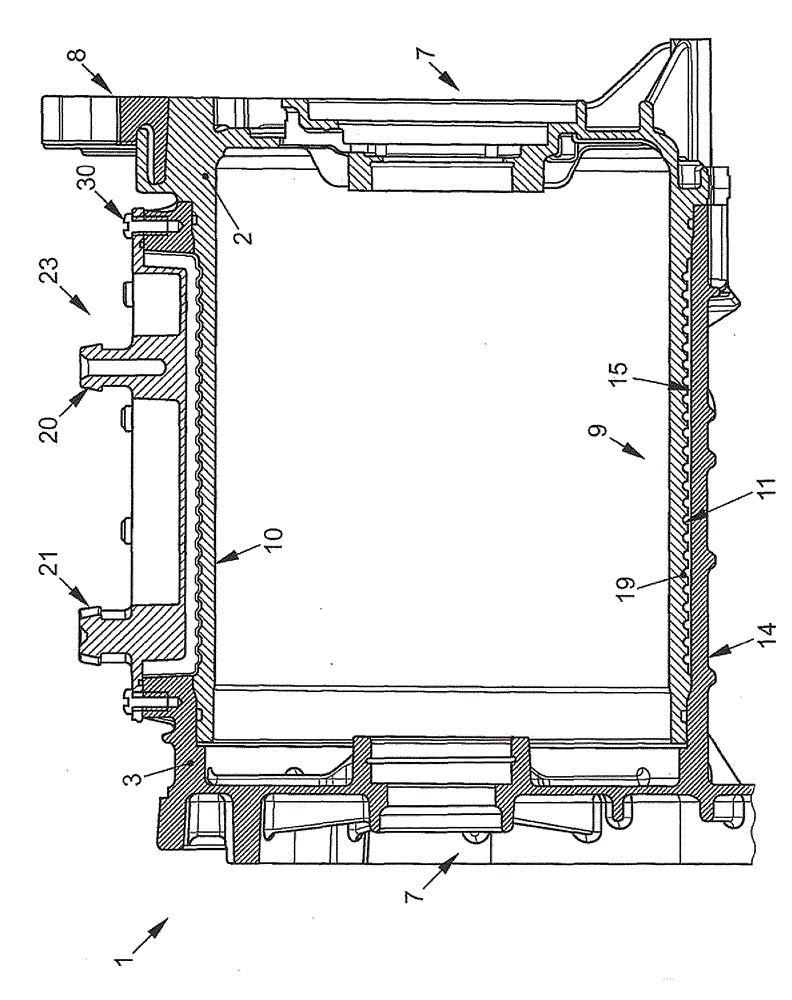

[0039] Figures 1 to 4 shows the housing 1 for the motor, which consists of the figure 1 and 2 The internal part shown in 2 and the image 3 3 components shown in the outer part. Figure 4 The housing 1 is shown with an inner part 2 and an outer part 3 . The housing 1 has a cooling jacket in which a coolant circulates and which receives and dissipates the heat of the electric motor. According to the invention such a housing can also be used for other heat sources or coolers to be cooled. The housing 1 according to the invention is described by way of example with the application of an electric motor. The motor includes a stator 4 and a rotor 5 . The rotor 5 is connected to a shaft 6 , which is fixed in the housing 1 for rotational movement via bearings 7 . The housing 1 consists of an inner part 2 and an outer part 3 , which conduct coolant.

[0040] figure 1 , 2 4 and 4 show the inner part 2, which comprises a bearing end shield 8 and a pipe section 9 having a pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com