A dirty oil filter cartridge

A filter cartridge, dirty oil technology, applied in the direction of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of filter impact, reduce the service life of the filter, increase the labor load of the staff, etc., to achieve protection Filter, impact reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

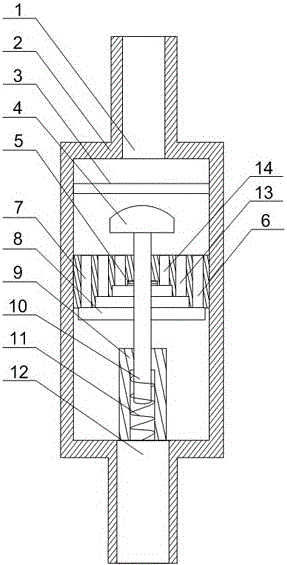

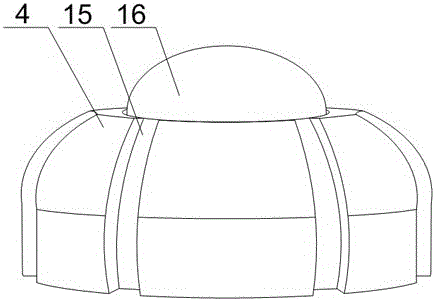

[0021] like figure 1 and figure 2 As shown, this embodiment includes a cylinder body 2 and an oil inlet 1 and an oil outlet 12 provided at the upper and lower ends of the cylinder body 2, and an isolation plate 7 is installed in the cylinder body 2, and the two ends of the isolation plate 7 They are respectively provided with discharge hole groups, and also include a support base 9 fixed in the cylinder body 2. A movable rod 10 is slidably arranged in the support base 9. A groove is arranged at the lower end of the support base 9. The lower end of the movable rod 10 passes through a spring. 11 is connected to the bottom of the groove, the upper end of the movable rod 10 passes through the isolation plate 7 and a stopper 4 is fixed at its end, the stopper 4 is facing the oil inlet 1, and the stopper 4 includes a frustum-shaped body, A ball 16 is rotated at the top of the body, and a plurality of guide grooves 15 along the axial direction of the cylinder body 2 are annularly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com