A production line for gluing and hemming of automobile door covers

A door cover gluing and production line technology, which is applied to the surface coating device, coating, feeding device, etc. It is difficult to guarantee and other problems to achieve the effect of stable and reliable product quality, smooth production rhythm, and short transformation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0026] Best practice:

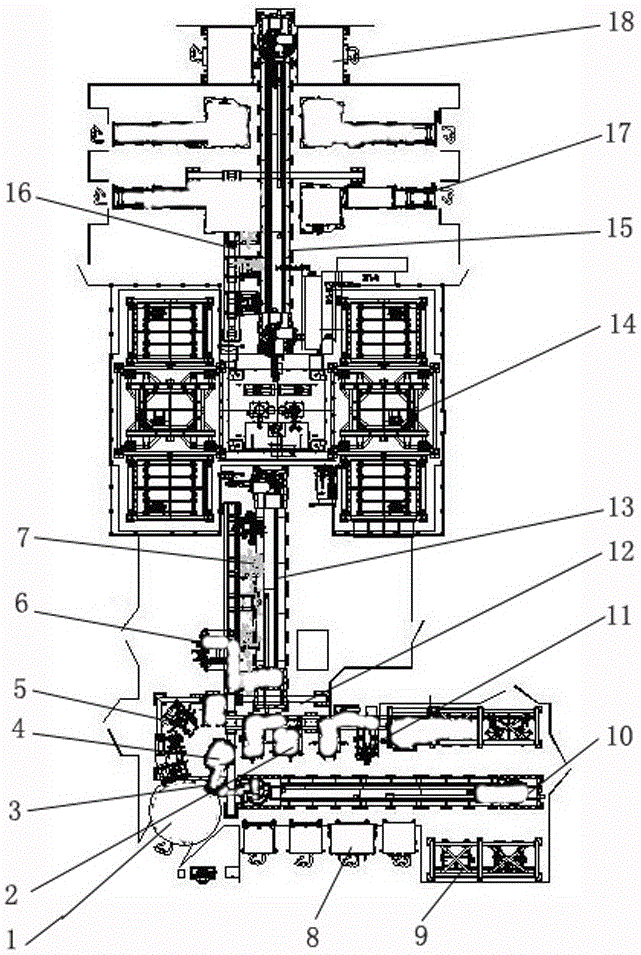

[0027] Such as figure 1 As shown, a production line for gluing and hemming of automobile door covers includes two parts of a gluing production line and a hemming production line docked with each other. The inner panel tetrahedron rotary table 1, glue gun, six-axis fixed robot 4, inner panel gripper storage rack 5 are arranged on one side, and the outer panel positioning platform 8 and the combined platform switching storage area 9 are arranged on the other side of the combining platform 12 , outer panel seven-axis robot 10, outer panel gripper storage rack 11; the hemming production line includes a pre-edging special machine 6, a press 14 and an inner hemming special machine 17 from front to back, and the pre-hemming special machine 6 and the press A fastening gripper storage frame 7 and a fastening seven-axis robot 13 are arranged between the presse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com