Simple pulley type reinforcement steel shear

A pulley and force-enhancing technology is applied in the field of simple pulley-enhanced steel bar shears, which can solve the problems of small shearing force, inconvenient maintenance and high cost, and achieve the effects of improving shearing force, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

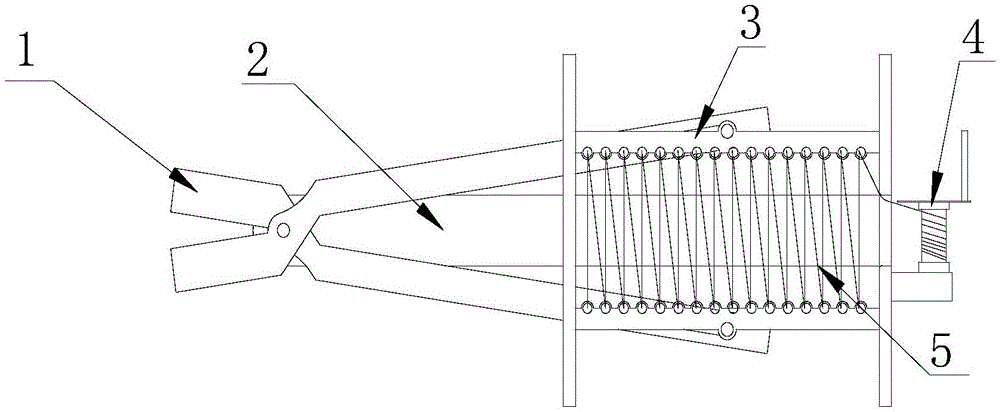

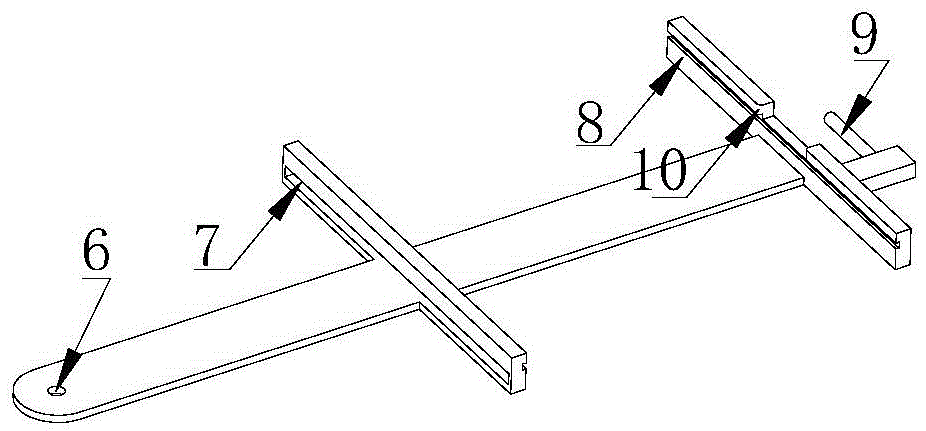

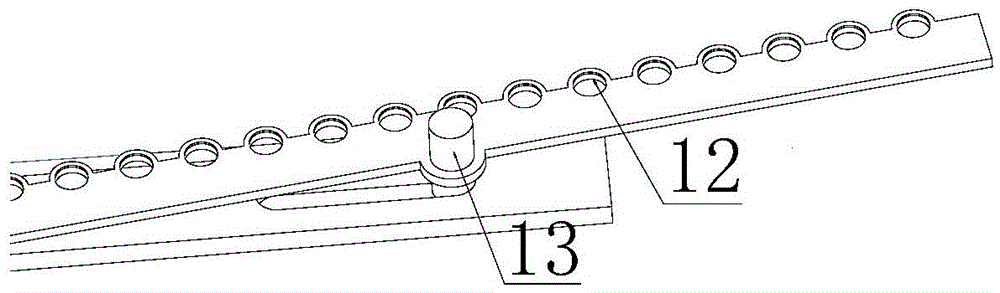

[0014] The invention adopts a simplified pulley block (threading hole) to increase the force, and improves the shearing force of the traditional steel bar shears. Such as figure 1 As shown in the figure, a simple pulley-type reinforced steel bar shear includes a pair of knife scissors 1, a frame 2, a limit frame 7, a limit plate 8, a take-up handle 4, a take-up handle installation shaft 9, two nylon ropes Frame 3, nylon rope 5, force pin 13.

[0015] Such as figure 2 As shown, the two blades of the pairing scissors 1 are hingedly fixed to one end of the frame 2, the limit plate 8 is installed on the other end of the frame 2, the take-up handle installation shaft 9 is installed on the limit plate 8, and the take-up The handle 4 is hinged on the take-up handle installation shaft 9; the limit frame 7 is installed on the frame 2 for installing the nylon rope frame 3; the tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com