Machine tool

A technology for machine tools and clamping arms, which is applied in the field of machine tools and can solve the problem that the clamping arms cannot be restored to the swinging action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

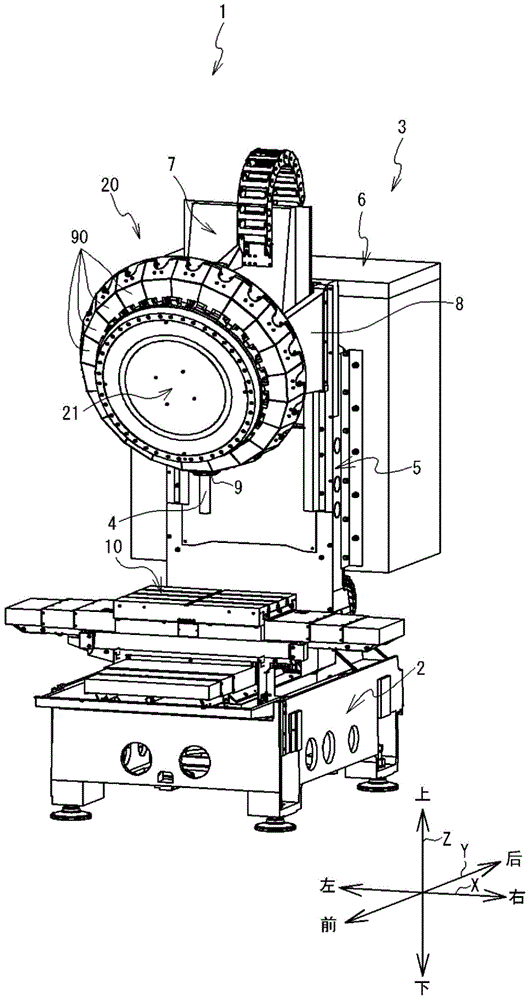

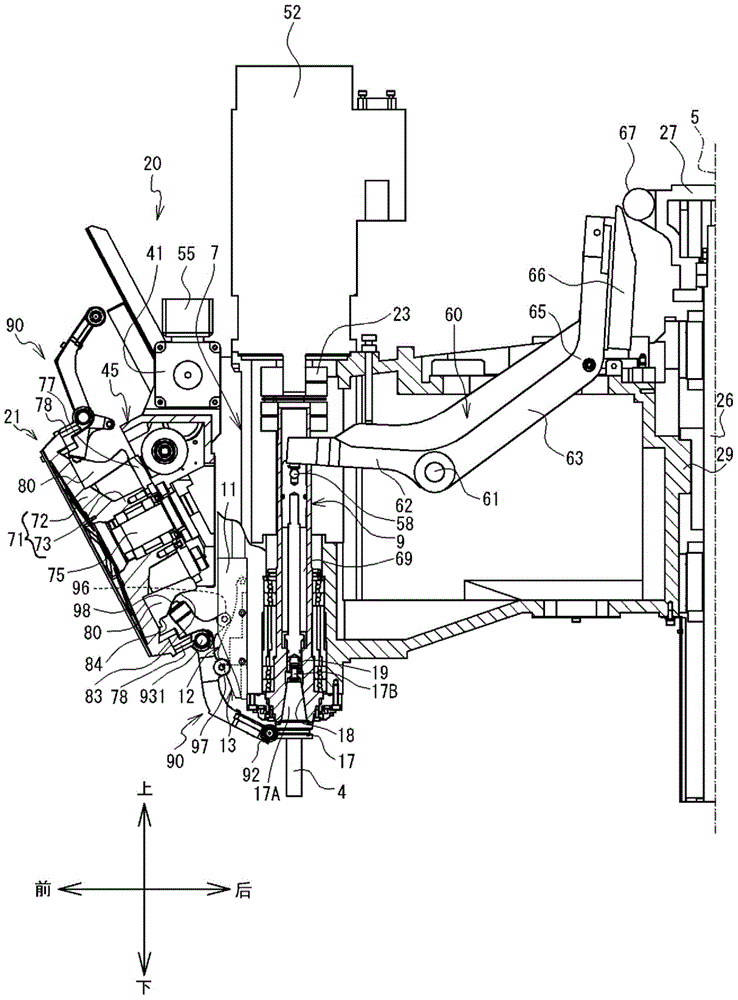

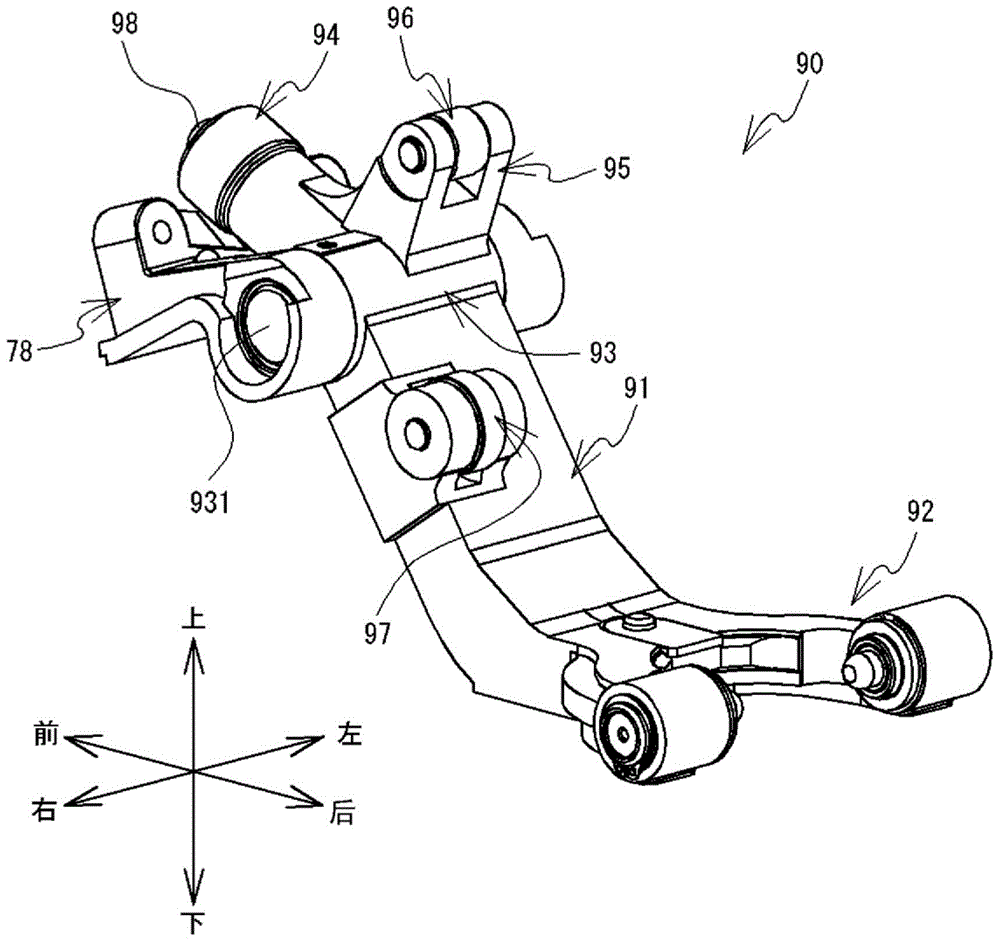

[0029] Embodiments of the present invention will be described with reference to the drawings. The following description uses up and down, left and right, and front and rear as indicated by arrows in the figure. The left-right direction, front-rear direction, and up-down direction of the machine tool 1 are the X-axis direction, the Y-axis direction, and the Z-axis direction of the machine tool 1, respectively. The Z-axis origin is the mechanical origin of the Z-axis. The machine origin is a position where the machine coordinates of the X-axis and the Y-axis are zero, and the machine coordinates of the Z-axis reach the upper limit of the machined object.

[0030] refer to figure 1 The structure of the machine tool 1 will be described. The machine tool 1 includes a machine base 2, a machine tool body 3, a workbench 10, a tool changing device 20, and the like. The base 2 is a substantially rectangular parallelepiped metal base. The machine tool main body 3 is provided behind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com