Circular arc surface edge grinding device of cylindrical component

A component and arc technology, applied in the field of arc surface edging device, can solve the problems of inaccuracy, complicated operation process, and influence on the grinding effect, and achieve the effect of facilitating promotion and implementation, good effect and uniform grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

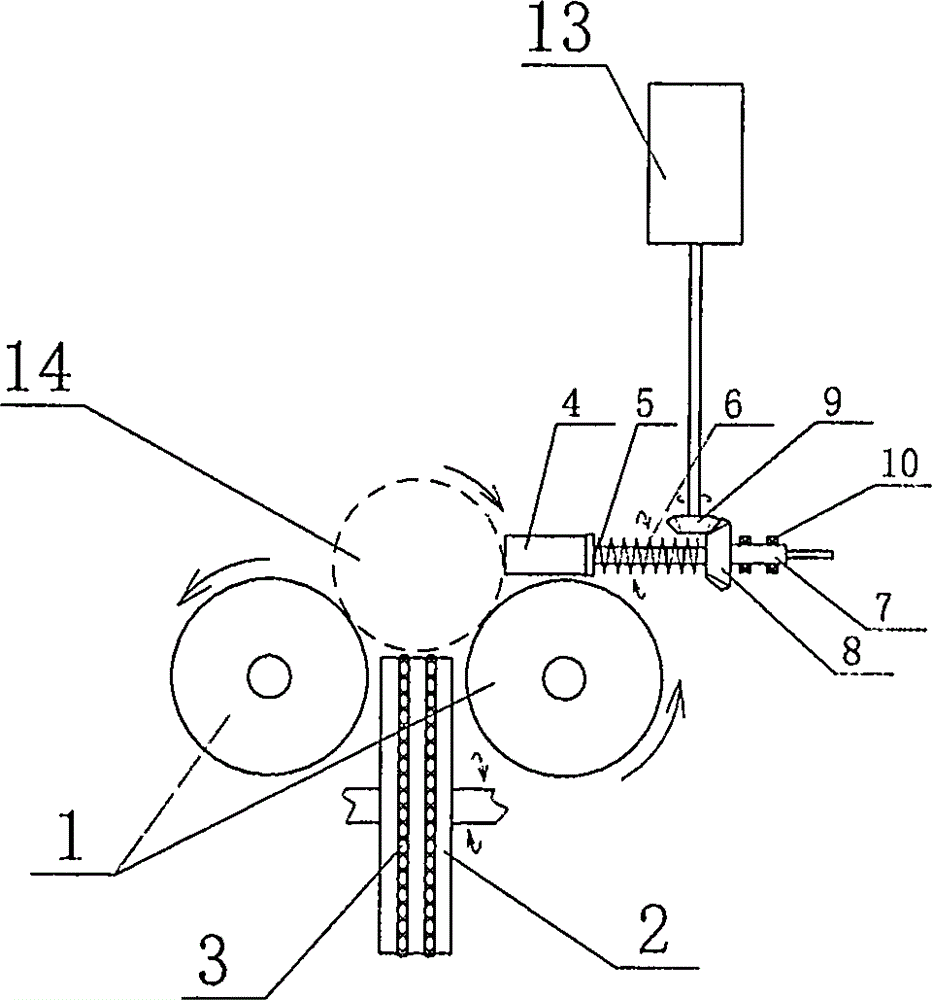

[0011] Embodiment 1: see figure 1 The first type of arc surface edging device for cylindrical members is equipped with a pair of parallel support rollers 1 parallel on the bracket; the two support rollers 1 are preferably kept horizontal. The two support rollers 1 are connected with the drive motor at the same time, and keep rotating in the same direction synchronously. The cylindrical workpiece 14 is placed between the two support rollers 1, so that the cylindrical workpiece 14 is driven by the two support rollers 1 to keep rotating. The two supporting rollers 1 can be rigid rollers or flexible rollers, depending on actual needs.

[0012] The two supporting rollers 1 are in gap fit, and a pushing mechanism is arranged in the gap between the two supporting rollers 1 . The pushing mechanism should include a plurality of horizontal rollers 2, and each roller 2 is connected to the power mechanism by transmission. An annular groove is arranged on the circumferential surface of e...

Embodiment 2

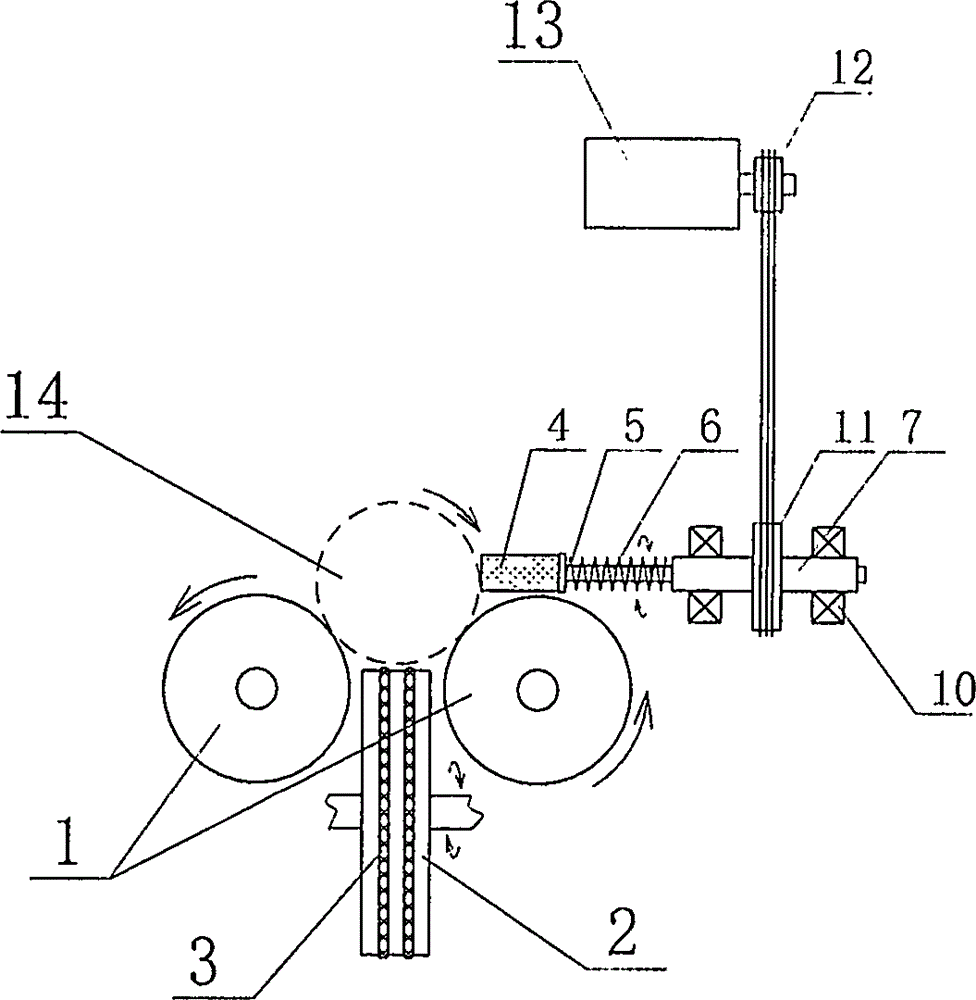

[0015] Example 2: see figure 2 , the arc surface edging device of the second cylindrical member, the content is the same as that of embodiment 1, the difference is that the transmission mechanism is changed, the transmission mechanism of the present embodiment is to install the driven pulley 11 on the rotary sleeve 7, Drive pulley 12 is installed on the motor rotating shaft, and drive pulley 12 is connected with driven pulley 11 by belt transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com