Novel curved jaw locking pliers

A technology of high-powered pliers and round mouth, applied in the field of new round-nosed high-powered pliers, can solve the problems of decreased clamping force of high-powered pliers, damage to workpiece surface, and increased replacement frequency of high-powered pliers, so as to increase processing speed, increase service life, reduce The effect of physical exertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

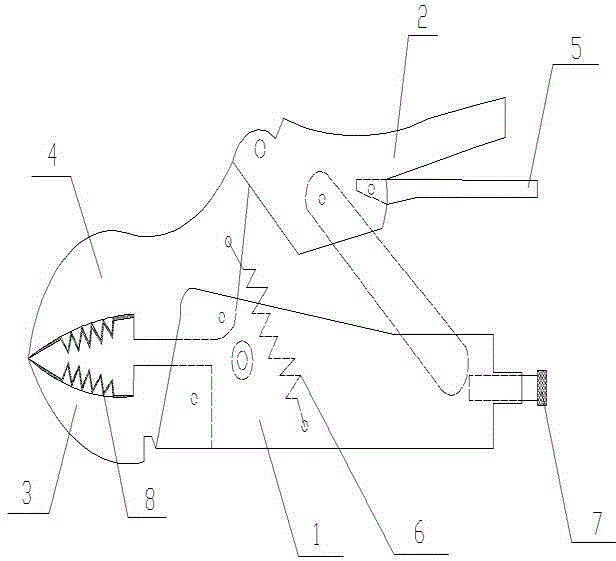

[0009] A new type of round-mouth pliers, comprising an upper pliers arm 1 and a lower pliers arm 2, an upper pliers mouth 3 is fixed on the head of the upper pliers arm 1, a lower pliers mouth 4 is arranged below the upper pliers mouth 3, and a lower pliers mouth 4 Connected with the lower tong arm 2 by rivets, the top of the lower tong arm 2 is provided with a movable pressing rod 5, the other end of the movable pressing rod 5 is fixed in the lower tong arm 2, and the middle part of the upper tong arm 1 is provided with a tension spring 6. 6 is connected with the lower pliers mouth 4, the tail of the upper pliers arm 1 is provided with an adjusting nut 7, and the upper pliers mouth 3 and the lower pliers mouth 4 are provided with a nickel-plated coating 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com