Preparation method of noctilucent fibers capable of emitting red light in darkness

A technology of luminous fiber and red light, applied in the field of preparation of luminous fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Provide a kind of preparation method of the luminous fiber that can emit red light in the dark, comprise steps are:

[0022] (1) Preparation of light conversion agent:

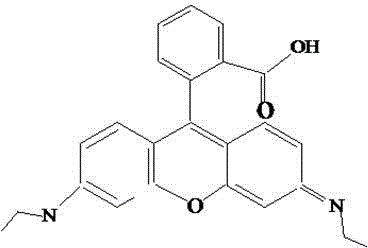

[0023] Add 1 part of 3-hydroxy-N,N-dimethylaniline into a container containing 30 parts of deionized water, stir (stirring speed 500 rpm), and add 1 part of 2-hydroxybenzaldehyde under gradual heating conditions , when the temperature rises to 50°C, add 0.02 parts of anhydrous zinc chloride and H 2 SO 4 0.02 parts. Seal the container and react for 18 hours at a constant temperature of 50°C with stirring. Open the container and stir constantly to evaporate the water. Finally, it was dried at 110° C. for half an hour to obtain a light conversion agent.

[0024] (2) Preparation of luminous particles:

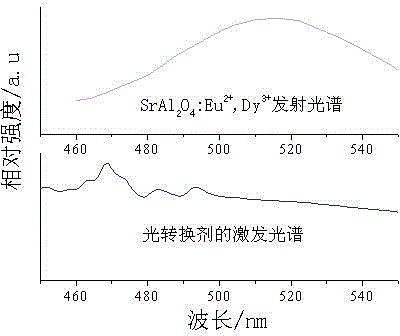

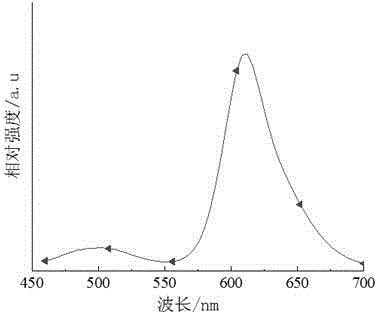

[0025] 0.1 part of photoconversion agent prepared in step 1 and SrAl 2 o 4 :Eu 2+ , Dy 3+ 5 parts and 20 parts of polyethylene terephthalate were mixed, melted and granulated to make luminous par...

Embodiment 2

[0028] Provide a kind of preparation method of the luminous fiber that can emit red light in the dark, comprise steps are:

[0029] (1) Preparation of light conversion agent:

[0030] Add 3 parts of 3-hydroxy-N,N-dimethylaniline into a container containing 40 parts of deionized water, stir (stirring speed 550 rpm), and add 3 parts of 2-hydroxybenzaldehyde under gradual heating conditions , when the temperature rises to 50°C, add 0.07 parts of anhydrous zinc chloride and H 2 SO 4 0.07 parts. Seal the container, and react at a constant temperature of 50° C. with stirring for 19 hours. Open the container and stir constantly to evaporate the water. Finally, it was dried at 110° C. for half an hour to obtain a light conversion agent.

[0031] (2) Preparation of luminous particles:

[0032] 0.15 part of the light conversion agent prepared in step (1) was mixed with SrAl 2 o 4 :Eu 2+ , Dy 3+ 7 parts and 26 parts of polycaprolactam were mixed, melted and granulated to make...

Embodiment 3

[0035] Provide a kind of preparation method of the luminous fiber that can emit red light in the dark, comprise steps are:

[0036] (1) Preparation of light conversion agent:

[0037] Add 7 parts of 3-hydroxy-N,N-dimethylaniline into a container containing 50 parts of deionized water, stir (stirring speed 600 rpm), and add 7 parts of 2-hydroxybenzaldehyde under gradual heating conditions , when the temperature rises to 50°C, add 0.1 parts of anhydrous zinc chloride and H 2 SO 4 0.1 part. Seal the container and react at a constant temperature of 50° C. with stirring for 20 hours. Open the container and stir constantly to evaporate the water. Finally, it was dried at 110° C. for half an hour to obtain a light conversion agent.

[0038] (2) Preparation of luminous particles:

[0039] Mix 0.2 parts of the light conversion agent prepared in step (1) with SrAl2O4:Eu2+, 10 parts of Dy3+, and 30 parts of polypropylene to make luminescent particles.

[0040] (3) Baking and drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminous brightness | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com