A construction method for dehydrating high-viscosity mud filled with pipe bags

A construction method and pipe bag technology, which can be used in filling, foundation structure engineering, construction, etc., and can solve the problems of difficult consolidation of weak mud layers, slow consolidation speed, and high cost of sand filling materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

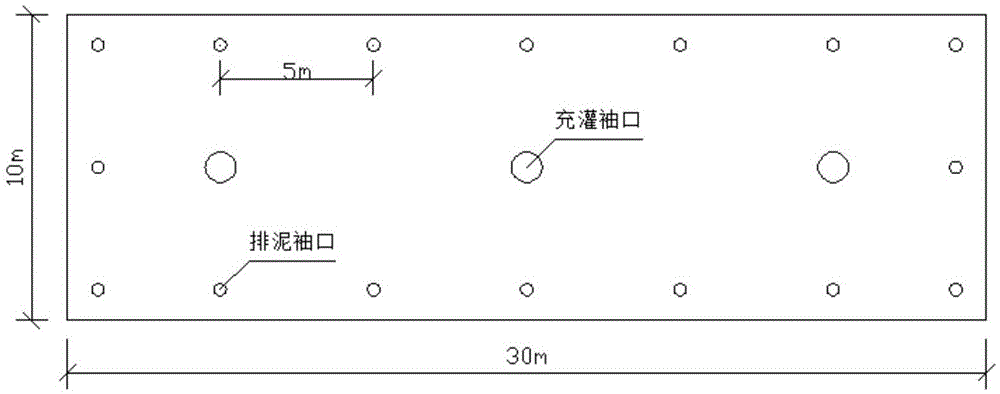

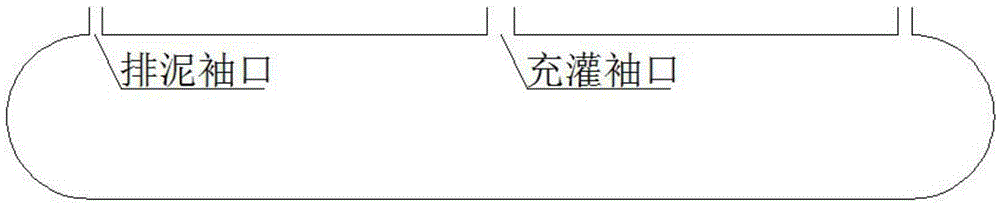

[0018] (1) Make the tube bag, and set up the mud discharge cuff while opening the filling cuff in the tube bag.

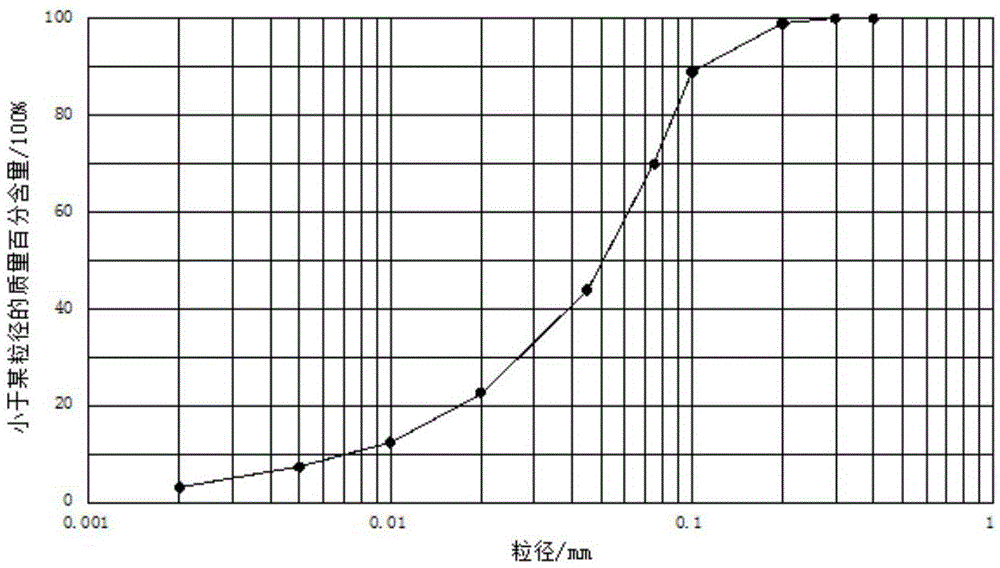

[0019] (2) For filling mud with a clay content greater than 10% and a sand content of only 30%-50%. The mud filling concentration is lower than 25%, and the low concentration is beneficial to the sedimentation and separation of soil particles with different particle sizes.

[0020] (3) For tube bags that require less than 1 hour for one filling to reach 85% fullness. When filling the pipe bag, tighten the mud discharge cuff, stop filling after the pipe bag is filled to 85% fullness, stand still for 10 minutes to fully settle the sand particles in the slurry in the pipe bag, and then untie the mud discharge cuff to release the surface layer of the pipe bag water and mud with more fine particles. After repeated filling and mud discharge for several times, the thickness of the pipe bag reaches 50cm and then stop filling.

[0021] (4) For tube bags that take more th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap