Fully hydraulic down-the-hole rotary percussion drill bit for piling in rock and soil layer

A combination drill bit and hydraulic impact hammer technology, which is applied in the direction of drill bit, earthwork drilling, drilling equipment, etc., can solve the problem that the pneumatic down-the-hole hammer hole wall is easy to collapse, and it is impossible to drill super large and super deep rock pile holes. Problems such as high damage rate of the main engine, achieve the effect of reduced output torque requirements, low cost, and reduced drilling pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

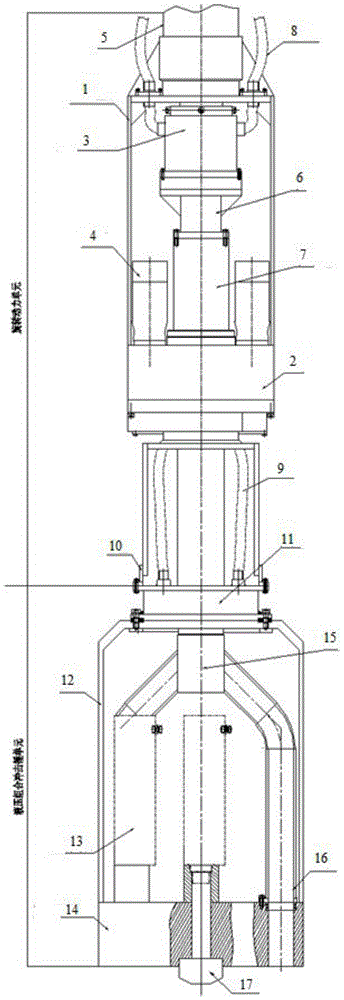

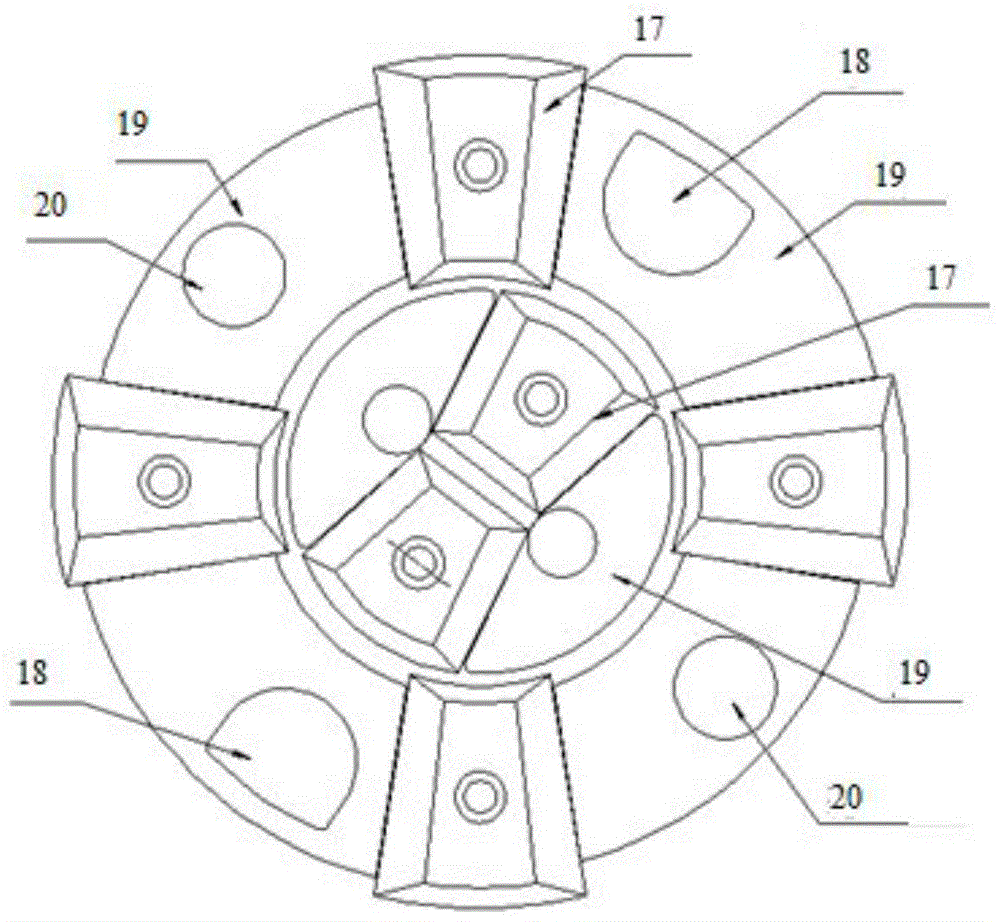

[0019] Figure 1-2 As shown, when working, the rotary power unit in the full hydraulic down-the-hole rotary impact drill bit is output by the hydraulic motor 4 or the hydraulic reducer through the gear set, and at the same time drives the rotation of the hollow shaft 6 and the hydraulic oil rotary joint 3, and drives Rotation of the hydraulic combined impact hammer unit to achieve rotary grinding; at the same time, the hydraulic combined impact hammer unit in the fully hydraulic down-the-hole rotary impact combined drill bit is transmitted from the impact energy output by the hydraulic hammer to the inlaid alloy hammer plate 17 on the fixed parent body 14 of the impact hammer , The impact energy of the inlaid alloy hammer plate 17 directly acts on the rock layer to achieve impact crushing; through the simultaneous action of rotating grinding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com