Sand screening and punching construction method of churn drill

A construction method and technology of percussion drilling, which are applied in earth-moving drilling, flushing wellbore, wellbore/well components, etc., can solve the problem that the thickness of sediment at the bottom of super-large diameter end-bearing piles easily exceeds the standard, the volume of mud drilling slag is large, and the The problems of too much equipment investment, etc., can improve the construction quality of pile foundation, reduce the investment of machinery and equipment, and speed up the cycle speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

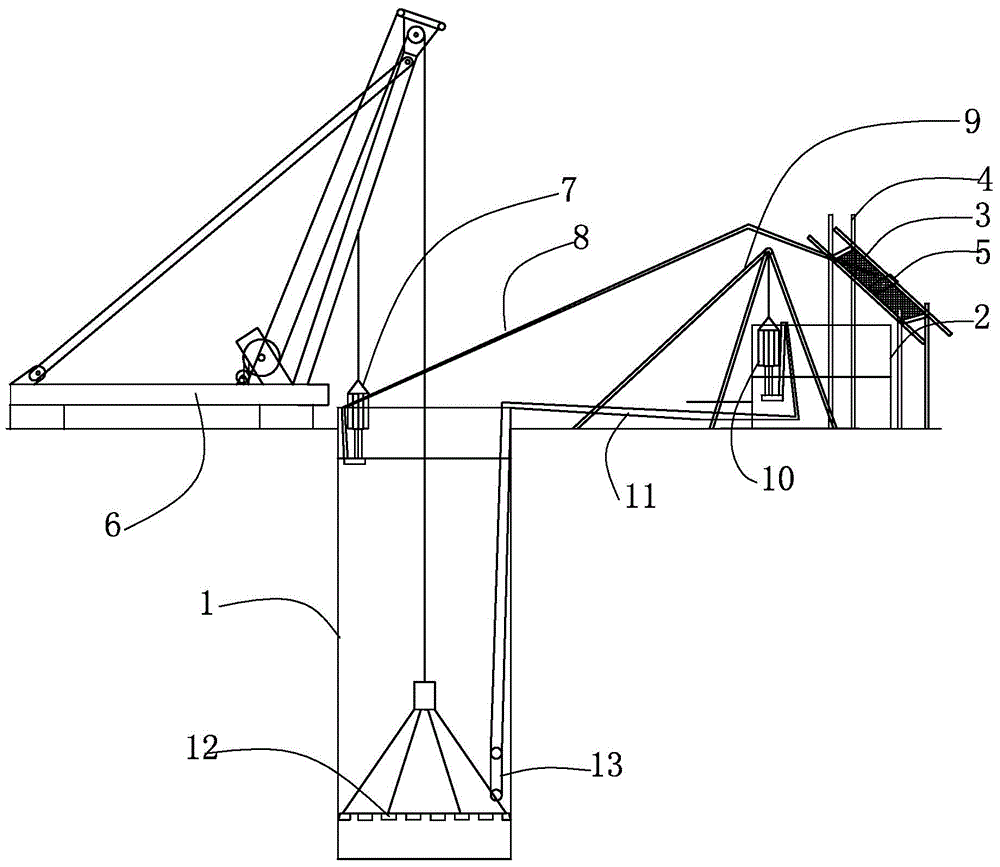

[0015] The device used in the present invention is as figure 1 As shown, the specific implementation steps are as follows:

[0016] (1) A mud tube 2 for storing mud is arranged near the pile hole 1, a filter screen 3 is arranged above the mud tube 2, the filter screen 3 is fixed on a filter screen bracket 4, and one end of the filter screen 3 is high One end is set with a low slope, and the edge of the lower end of the filter screen 3 is located outside the edge of the mud cylinder 2; a vibrator 5 is arranged in the middle of the filter screen;

[0017] (2) Suspend a slurry pump 7 on the handlebar of the impact drill 6 by a chain block, suspend the slurry pump 7 in the pile hole 1, connect the slurry pump 7 to a slurry pipe 8, and place the slurry pump 7 The outlet of the slurry outlet pipe 8 is placed above the filter screen 3;

[0018] (3) a tripod 9 is set on one side of the mud tube 2, a slurry delivery pump 10 is suspended by a chain block on the support point of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com