Flat-plate collector double-group slope type semi-automatic cover plate assembly machine

A flat-plate collector and slope type technology, which is applied in the field of flat-plate collector double-group slope type semi-automatic cover plate assembly machines, can solve the problems of complicated changes, complex systems, and large machine footprint, and can meet the scope of product specifications. Wide, flexible and versatile, the effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is the best example of the double-group slope-type semi-automatic cover plate assembly machine for flat-plate collectors described in the present invention, and does not limit the scope of protection of the present invention.

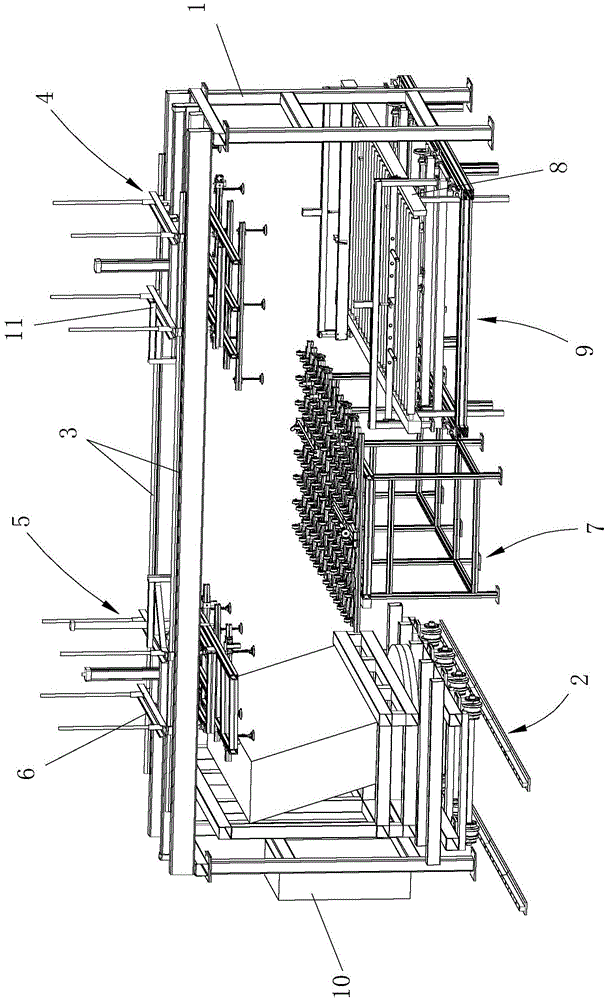

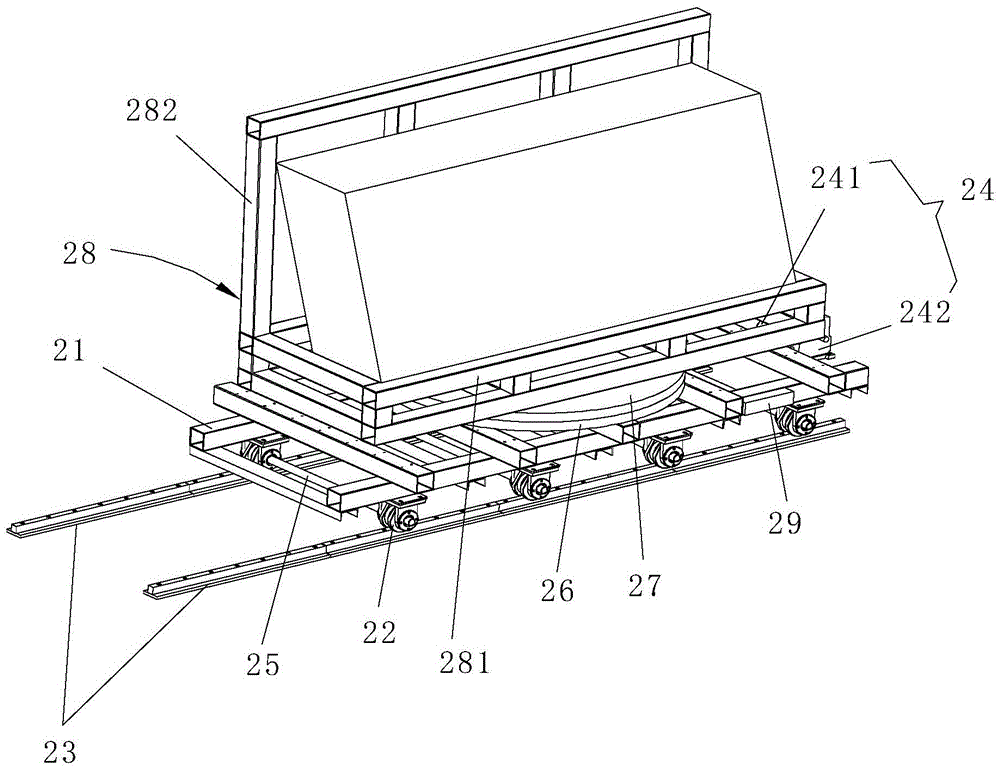

[0030] Please refer to figure 1 , the figure shows a double-group slope-type semi-automatic cover plate assembly machine for flat-plate collectors, including a gantry frame 1, and a slope-type cover plate loading vehicle 2 is arranged in turn in the assembly area below the gantry frame 1 for the cover. The cover plate positioning mechanism 7 for positioning the board before assembly and the frame positioning mechanism 9 for positioning the frame, the frame positioning mechanism 9 is provided with a frame roller line 8 for conveying the frame, and the top of the gantry 1 is provided with a main rail 3 , the main rail 3 is slidably connected with a first slider seat 6 and a second slider seat 11, and the first slider seat 6 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com