Thread sleeve type mounting bracket for balcony wall-mounted type solar water heater heat collection plate as well as mounting method and application thereof

A technology for solar water heaters and mounting brackets, which is applied to solar thermal devices, solar thermal power generation, heating devices, etc., and can solve the problem of inability to realize continuous adjustment of the inclination angle of solar water heater collector plates, inability to adapt to changes in direct sunlight angles, and inability to adapt to balcony installation and other issues, to achieve good economic and social benefits, low manufacturing costs, and enhance the effect of heat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

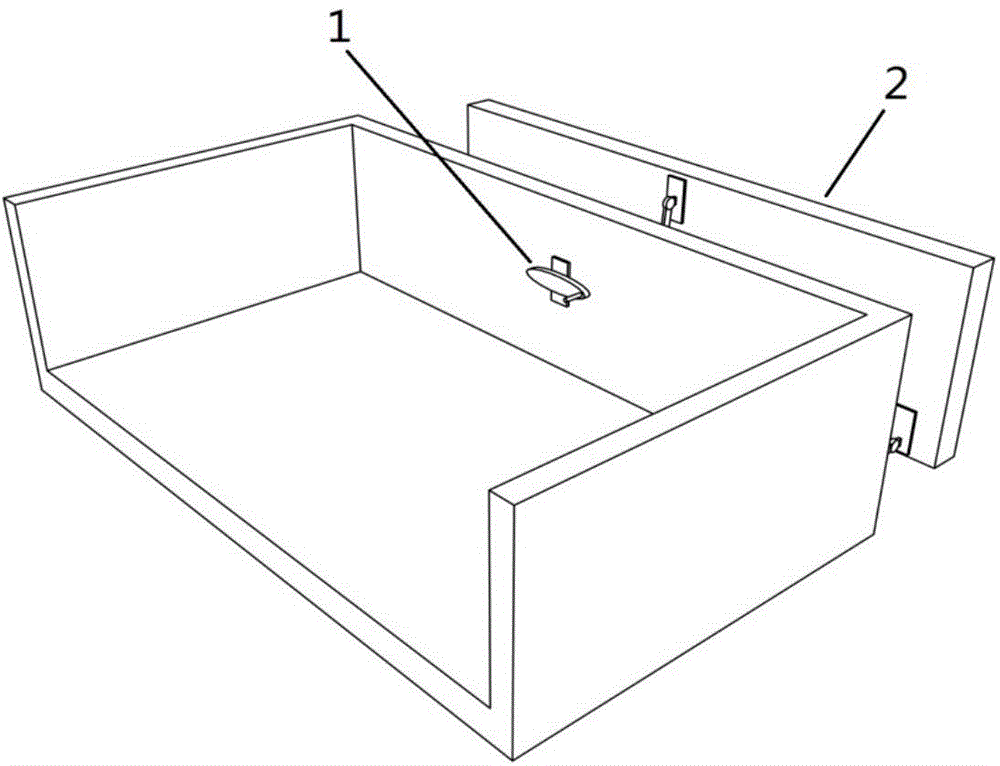

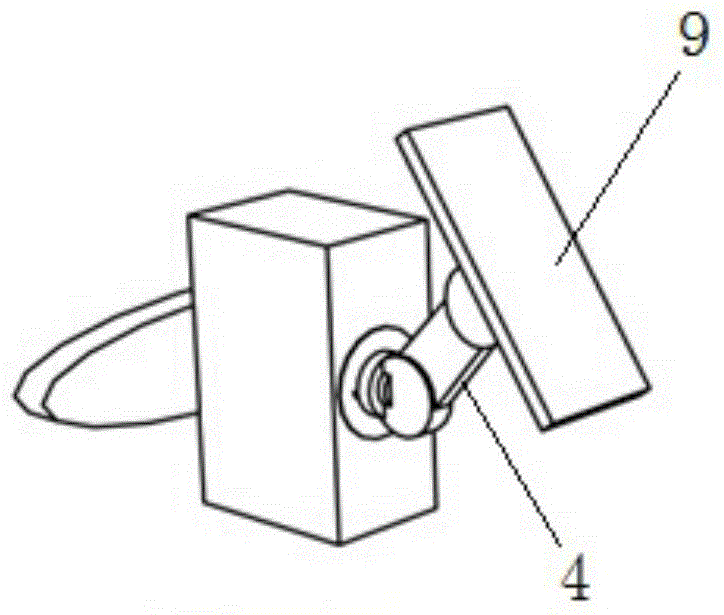

[0032] This embodiment provides a threaded sleeve-type installation bracket for a balcony wall-mounted solar water heater collector plate, the installation bracket includes a support rod, a drive rod and a connecting rod; the end of the support rod is fixed on the balcony wall On the outside, the front end of the support rod is hinged to the back of the heat collecting plate 2; The driving rod is positioned above the supporting rod, and the driving rod can be fixed on the upper edge of the balcony wall. When in use, the connecting rod 4 is pushed by the driving rod, so that the angle of the connecting rod 4 changes, and the angle of the heat collecting plate 2 is correspondingly rotated to realize the angle adjustment of the heat collecting plate 2 .

Embodiment 2

[0034] This embodiment provides a threaded sleeve mounting bracket for the heat collecting plate of a balcony wall-mounted solar water heater. The structure is as described in Embodiment 1. In the hole, the end of the drive rod is located in the balcony. During operation, in the balcony, by pushing the end of the driving rod, the driving rod pushes the connecting rod 4 to change the angle of the connecting rod 4 . Since the driving rod runs through the through hole on the wall, when the end of the driving rod is manually pushed, the driving rod travels more stably during the process of being pushed, and the position deviation does not occur, and the adjustment is smoother.

Embodiment 3

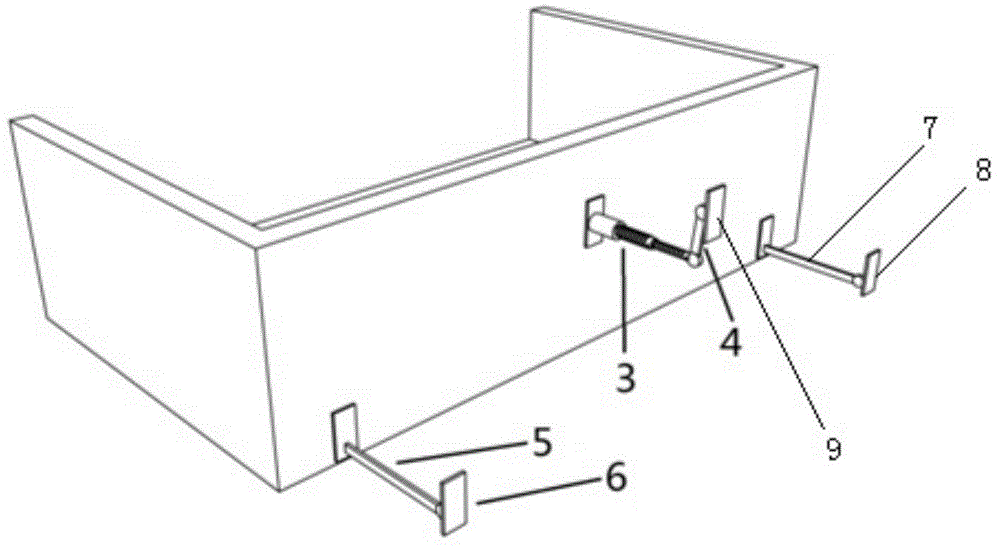

[0036] This embodiment provides a threaded sleeve-type installation bracket for the heat collector plate of a balcony wall-mounted solar water heater. And the second support rod 7, the length of the first support rod 5 and the second support rod 7 is 45cm, the spacing between the first support rod 5 and the second support rod 7 is 140cm, the first support rod when installed on the wall Bar 5 and the second support bar 7 are located on the same horizontal line, and the drive bar is positioned on the mid-perpendicular line between the first support bar 5 and the second support bar 7, and the vertical distance from the drive bar to the first support bar is 60cm. through holes in the wall. The installation positions of the three are as follows: figure 2 with Figure 4 shown.

[0037]The advantage of the technical solution provided by this embodiment is that the installation positions of the first support rod, the second support rod and the driving rod form an isosceles triangl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com