Vacuum cooling warehousing and vacuum delivering system for high-viscosity materials

A vacuum-pumping and high-viscosity technology, applied in the chemical industry, can solve the problems of uneven local temperature, inaccurate measurement, uneven local temperature, etc., and achieve the effects of avoiding moisture residue, rapid and uniform cooling, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

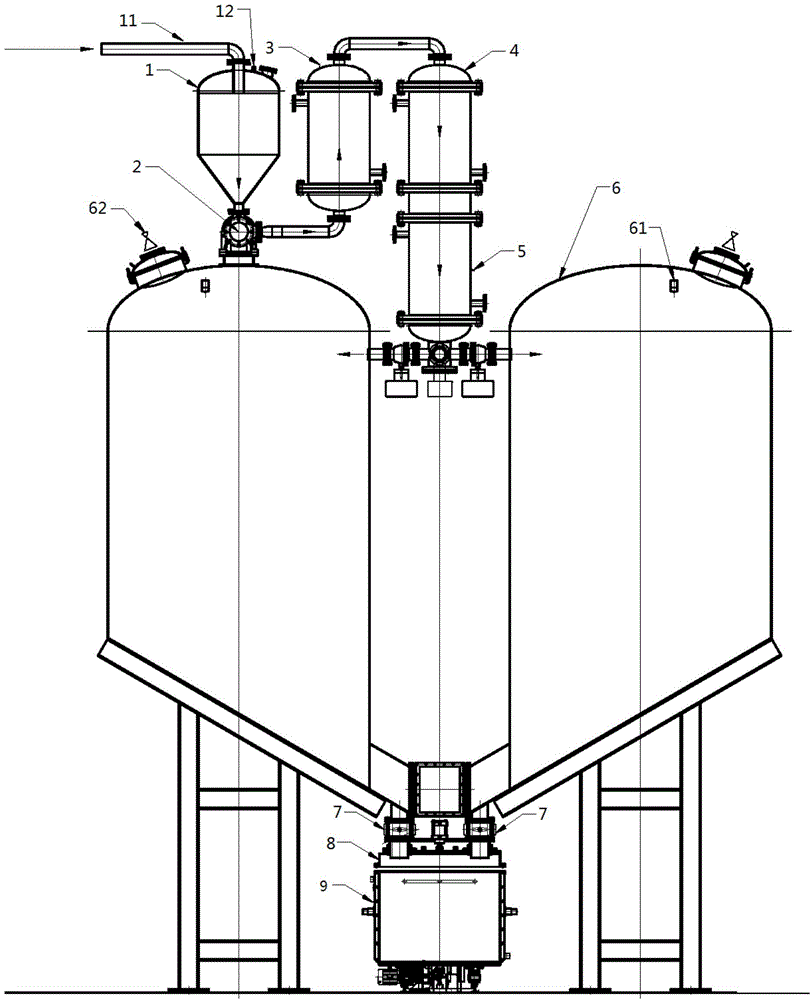

[0018] refer to figure 1 , a high-viscosity material vacuum cooling into the warehouse and vacuum out of the warehouse system, including a hot and humid gas extraction tank 1, the upper part of the hot and humid gas extraction tank 1 is provided with a feed pipe 11 and a vacuum port 12, and the hot and humid gas extraction tank 1 The lower part is an inverted cone, and the bottom of the inverted cone is provided with a discharge port, which is connected to the feed port of the material pump 2; the material pump 2 is a gear pump, with a feed port on the upper part and a discharge port on the side. The side outlet of the material pump 2 is connected in series with the first condenser 3, the second condenser 4, and the third condenser 5. The first condenser 3, the second condenser 4, and the third condenser 5 are tube-and-tube condensers. wherein the first condenser 3 flows upwards, the second condenser 4 and the third condenser 5 flow downwards; the bottom of the third condenser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com