Magnetostrictive displacement sensing flowmeter and flow measuring method

A magnetostrictive and flowmeter technology, applied in the direction of volume/mass flow generated by electromagnetic effects, can solve the problems of inability to realize automatic control, flowmeter measurement error, high maintenance cost, etc., achieve high reliability, eliminate pulsation, and resist Strong pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

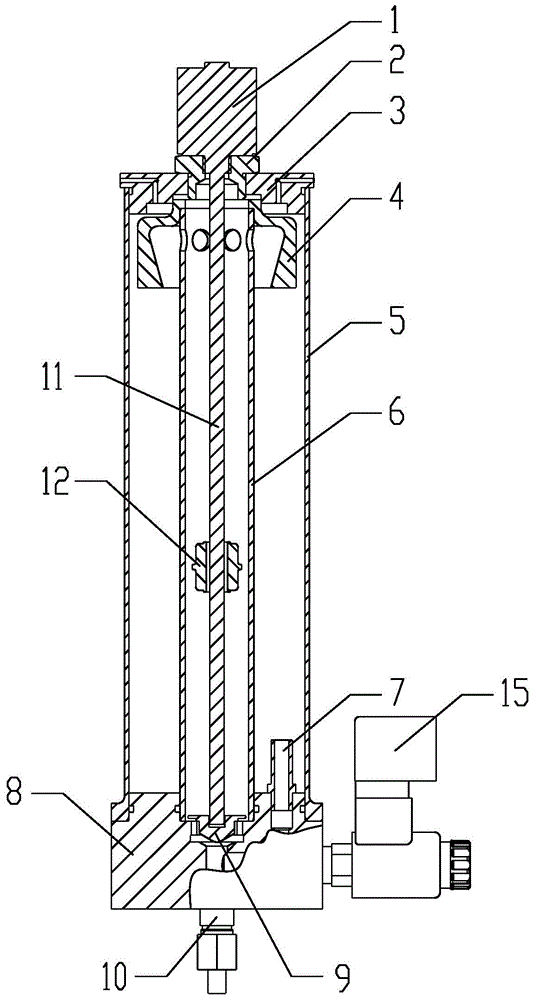

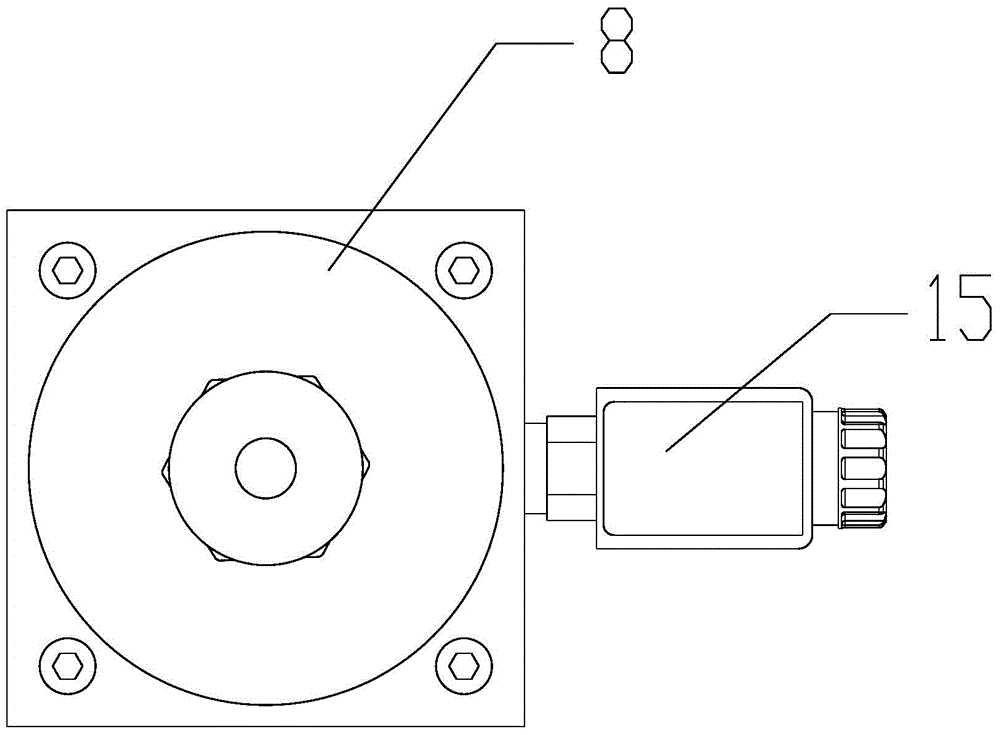

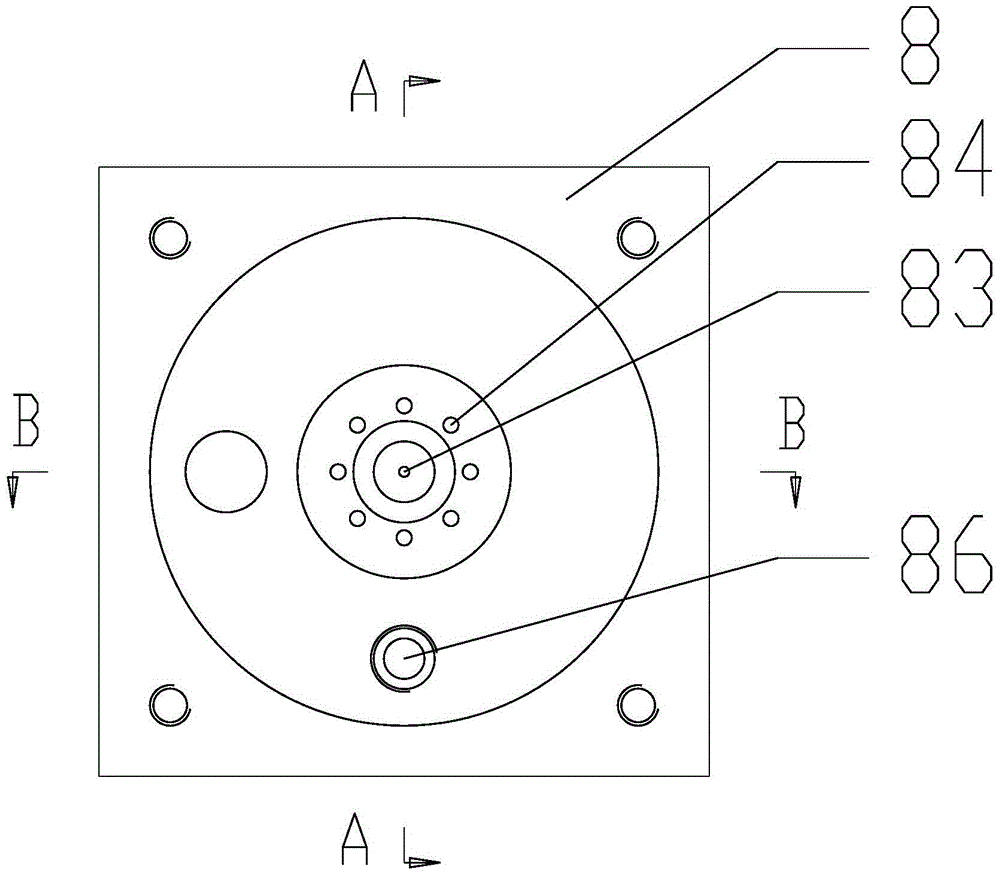

[0032] Such as Figure 1-Figure 7 As shown in the figure, a magnetostrictive displacement sensor flowmeter includes a sensor electronic chamber 1, a transition joint 2, a tank cover 3, an overflow tank 5, a metering barrel 6, a valve block 8, a damping gasket 9, a straight joint 10, and a measurement The waveguide 11 and the magnetic ring buoy 12 are characterized in that: the measuring waveguide 11 is a circular magnetostrictive material with a copper wire inside, the lower end of the measuring waveguide 11 is connected to the damping washer 9, the upper end of the measuring waveguide 11 is connected to the The sensor electronic warehouse 1 is connected, and the magnetic ring buoy 12 is freely movably set on the measurement waveguide 11. At the same time, the measurement waveguide 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com