Test stand for power systems of automobiles, and automatic test method of working conditions

A power system and test bench technology, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as the impracticality of dynamic working condition simulation, and achieve the effect of strong authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

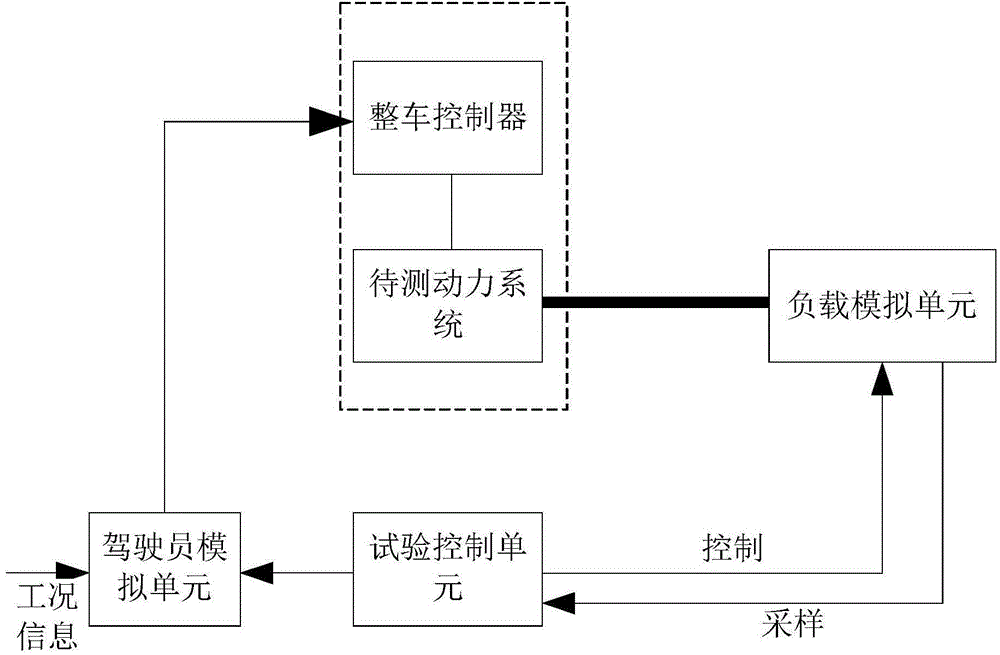

[0036] like figure 1 As shown, a vehicle powertrain test bench includes:

[0037] The load simulation unit is used to simulate the road load and is connected to the drive system to be tested; the load simulation unit is generally selected as a controlled rotating device, such as a dynamometer.

[0038] The test control unit is used to control the load simulation unit; the test control unit is based on vehicle information set in advance, such as vehicle weight, windward area, road resistance and other parameters, and at the same time according to the current actual vehicle speed, using the principle of vehicle dynamics to calculate The resistance suffered by the vehicle is transmitted to the load simulation unit in the form of target torque.

[0039] A driver simulation unit, the input interface of the driver simulation unit is used to input working condition information, and is also provided with a control interface for connecting with the vehicle controller of the power syst...

Embodiment 2

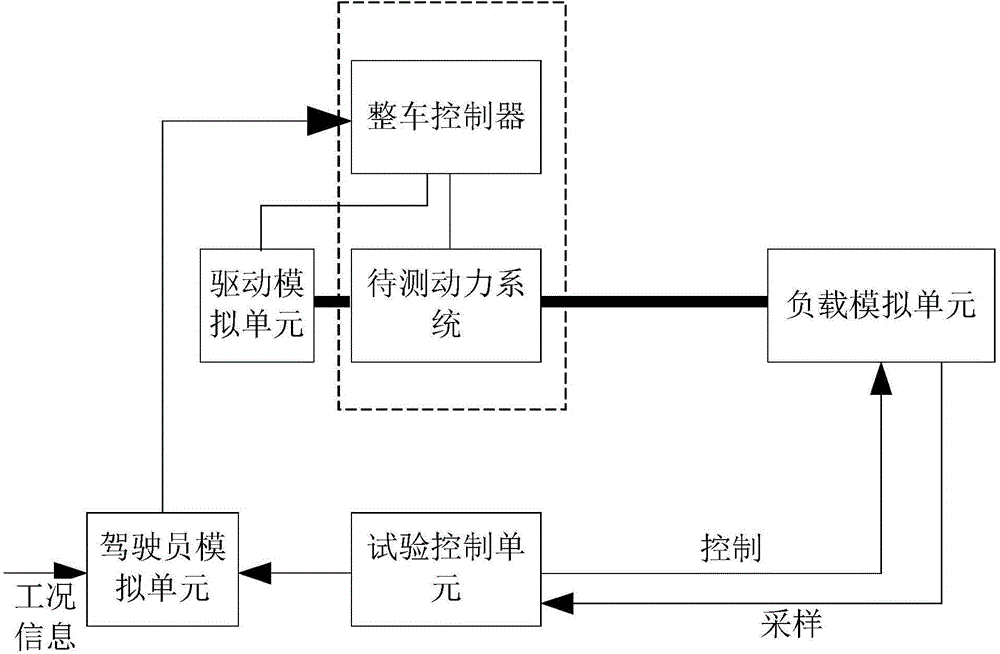

[0045] like figure 2 As shown, the difference from Embodiment 1 is that the test bench further includes a driving simulation unit for simulating the driving equipment. The driving equipment refers to the engine, driving motor, etc. If the driving simulation unit simulates the engine and the power system to be tested is an electric power system, the test system as a whole simulates a hybrid power system.

[0046] In Embodiment 1, the vehicle controller can exert control on the power system to be tested, specifically to control the driving mechanism in the power system to be tested. In embodiment 2, because the driving simulation unit is added, in order to control the acceleration and deceleration of the power system to be tested, it is also necessary to control the driving simulation unit.

[0047] If the driving simulation unit simulates the motor, the vehicle controller can control the driving simulation unit for simulating the motor through the corresponding motor controll...

Embodiment 3

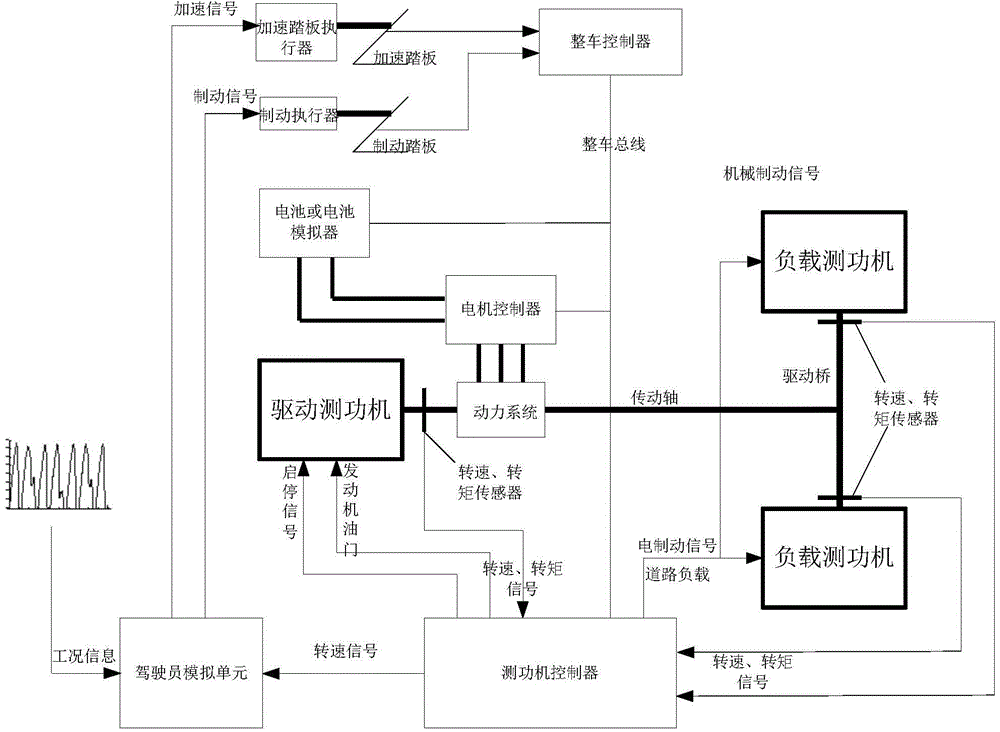

[0052] The difference between this embodiment and embodiment 2 is:

[0053] First, the control interface of the driver simulation unit is connected to the vehicle controller through the execution device. The above-mentioned actuators refer to the accelerator pedal actuator and the brake actuator. The acceleration signal and the brake signal generated by the driver simulation unit are sent to the accelerator pedal actuator and the brake actuator respectively, and they respectively control the accelerator pedal and the brake pedal. . Both the accelerator pedal and the brake pedal are part of the vehicle whose power system is to be tested, and this form can also take into account the testing of the accelerator pedal and the brake pedal. In addition, the brake pedal is also associated with the vehicle's mechanical brake mechanism, thereby enabling testing of the mechanical brake mechanism as well.

[0054] Second, the test control unit (in this embodiment, the test control unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com