Blanking fracture surface quality detection system based on machine vision and blanking fracture surface quality detection method based on machine vision

A machine vision and detection system technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of low efficiency, lack of accuracy and standardization, slow manual detection speed, etc., to improve service life, improve production efficiency, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

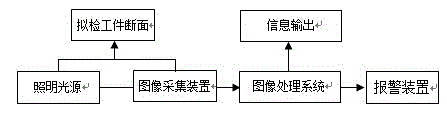

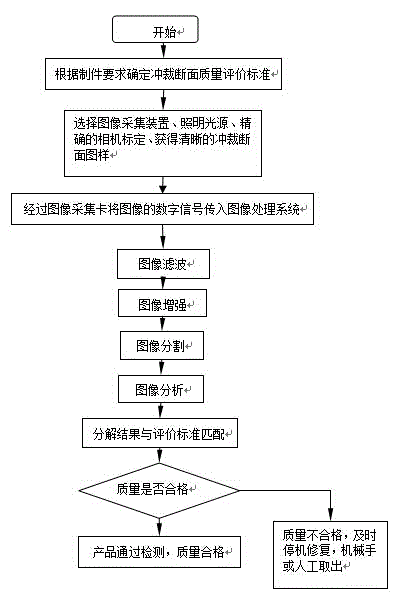

[0024] The structure diagram of the present invention is as figure 1 As shown, the punching section quality inspection system based on machine vision of the present invention includes an image acquisition device, an illumination source and an image processing system, wherein the illumination source is placed at a position capable of illuminating the workpiece to be inspected, and the image acquisition device is placed The position of the workpiece is to be detected, and the signal output end of the image acquisition device is connected with the signal input end of the image processing system.

[0025] In this embodiment, the above-mentioned image acquisition device is an industrial camera.

[0026] In this embodiment, the above-mentioned illumination light source is an LED light source.

[0027] In addition, the above-mentioned image processing system is also connected with an alarm device. The above image processing system is also connected with a display device. For infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com